How Vishwamdev Bhotica built a factory - with a little bit of music on the side - The Noel D'Cunha Sunday Column

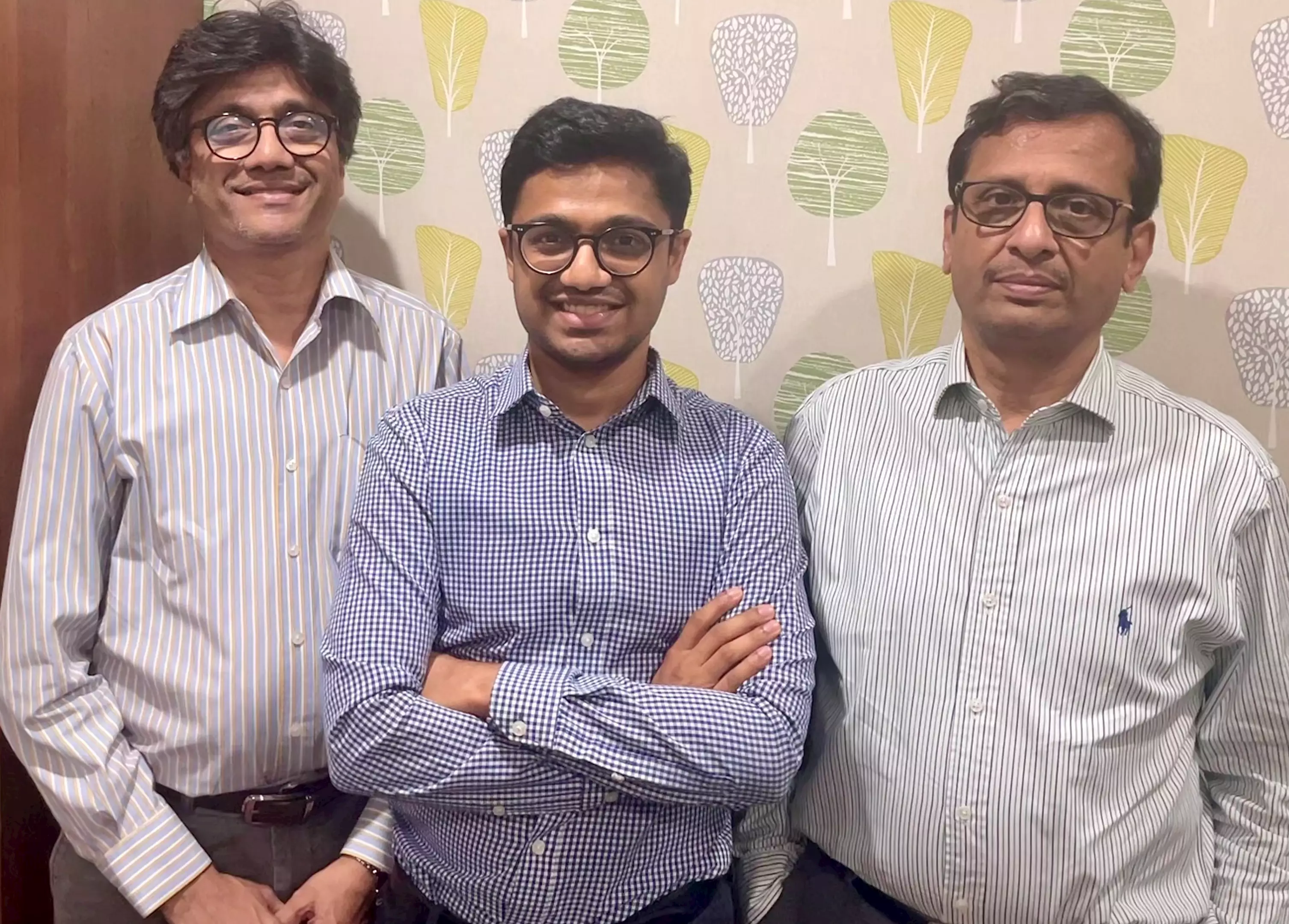

He is young, he is well informed. There is no faux naivety about him. He knows he is part of a huge print legacy, and so, he is determined to create the perfect blueprint for the future of Sapco.

A Sunday Column special with the 32 year-old man who loves rock and roll, plus all things packaging

01 May 2022 | By Noel D'Cunha

When he is not busy working in his family-owned company, Vishwamdev Bhotica loves to jam with his music band – In Between, and strumming his Fender American Elite Stratocaster. For Bhotica, music is the long hard path to happiness. And music comes naturally to the 32-year-old gen-next in the Bhotica family. “No formal education,” he says, “I got into music by listening in school and being influenced by friends.”

They say, rhythm and blues are the main innovators behind the development of rock and roll music. And behind the exuberance of the music there is lots of hard work. All the musical greats have said so. Every hour of their life is dedicated to riyaaz. Bhotica echoes the same note with a studious earnestness. “I love my work, but at the end of the day, it can drain you both physically and mentally. It can impact productivity and creativity. A break, in the form of pursuing a hobby that challenges you, fuels creativity, is life-enriching and in turn makes one a better entrepreneur. I can say that for sure,” says Bhotica, the technical director at Shree Arun Packaging, popularly known as Sapco.

Sapco was founded by Bhotica’s grandfather, Narayan Prasad Bhotica in 1970. It was equipped with letterpress and the mandatory hand-platen punching machines. Until 1995, Sapco operated from a unit in Lower Parel with its wrapper production unit.

“It was my grandfather who saw a future in the printing and packaging industry. He kept wrapper production at the heart of its business, says Bhotica, whose uncle, Hemant and father, Tushar, made Sapco’s first major expansion, moving to Navi Mumbai into a 10,000 sqft site, and a few years later into a 30,000 sqft site. The Sapco top-level confabulations were convened in the car during the longish drives. “The vision was – make Sapco a comprehensive printing and packaging unit – growth in clientele as well as the addition of printing machines, converting and finishing kit. We moved our focus towards the carton packaging vertical and how we could tap into voluminous, repeat orders.”

The origins of print

Bhotica has a diploma in printing technology from Germany and a Master's in Business Management (family-managed business) from SPJIMR, Mumbai. Curiously enough, his first act of printing wasn’t on the shop floor but in a print school in Germany. “I distinctly remember matching colours, and it was one of the finest lessons.”

And how has that helped Bhotica, especially in this day and age of ink kitchens and the science of swatches? “Ink is the first thing you apply on any substrate. It appears differently on each substrate, and since we have multiple paper substrates to choose from we have to keep in mind its inherent colour and absorbency,” he explains.

Although ink adds up to a very small percentage on the cost sheet, it determines the quality of the print to a very large extent. “The registration of each colour, the accuracy of the reproduction, and since recently, the Delta E references. Everything adds up and gives a high-quality print. At Sapco, we are very particular about our ink process and have tried to imbibe this thinking into the DNA of our team.”

The investment chronicles

Today, Sapco operates from a single unit spread over a 60,000 sqft site near Kalyan where it moved in 2021. According to Bhotica, the best thing about the plant is the design. This allows for smooth flow of material between each process.

Bhotica says he took note of what he learned under Boman Moradian in the management school. “We have kept it a U-shaped workflow, which is ideal for our industry. It minimises the time between each process and improves efficiency and floor management. We believe that in a certain space, the quicker the output of the production cycle, the more jobs and quantity we can execute in the same amount of time will help us in making it a more efficient plant. Hopefully, this should reflect in our numbers and most importantly, the bottom line,” he adds.

The company is equipped with a Heidelberg CD 102 six-colour coater press with full UV, a Manroland five-colour press with coater. In the converting and finishing department, it has a Brausse foil stamper, a brand new Bobst Novacut 106E 3.0 with stripping, elevated machine pile height up to 1800mm and a corrugation kit and runs at a speed of up to 8,000 sheets per hour, and a Bobst Expertfold 80 A2 with Accubraille GT. The Bobst Expertfold can run at a belt speed of up to 450m/min. In the pre-press, Sapco is equipped with a Screen CTP, and a Esko Kongsberg sample maker.

Bhotica’s favourite packaging job? “We have a few jobs in which we were able to utilise the machine's maximum features like stripping at the die-cutting stage to reduce manual stripping and quick turnaround. In pasting, we deployed the Speedwave for a large volume lock-bottom carton with partition flaps and a header,” says Bhotica, adding, that he cannot reveal the client names.“There is the client secrecy clause we sign with our clients."

The impressive equipment lines notwithstanding, Bhotica thinks a dream kit for print would be one of the top branded seven-colour coaters, and in die-cutting, it has to be the Bobst Mastercut and for folding-gluing, the Bobst Expertfold.

Sapco is certified with the latest ISO 9001 and has plans to add certifications such as BRC, FSSC, PS9000, SEDEX as per client request.

Corrugation: What a wonderful world

Since 2015, corrugation has become an in-house project. Bhotica says, both his uncle Hemant and father Tushar, who manage the business as directors of Sapco, knew that to do top quality and quick turnaround times with larger volumes, the company would need an automatic flute laminator.

Bhotica says the flute laminator is possibly the most under-rated packaging kit, though Sapco recently invested in one. “We are slightly conservative in our approach. We believe in investing once we have the business rather than adding extra capacity without any surety. Once we started notching a certain critical mass in terms of volumes, the move to invest in an automatic set-up became a straightforward decision. We had planned the investment at the time of moving into our new facility, and things fell into place by the end of 2021.”

How does Sapco choose a kit, what are the technology discussions? We evaluated brand new options as well as used options thoroughly before making our decision,” Bhotica says. “We evaluated based on cost, quality, speed/output, life, feedback by users, number of installations in Western India, parts availability and service backup. We went ahead with a used Meiguang flute laminator serviced by Suba solutions, and are content with our decision.”

The Sapco song

Like many of the best breed of young business owners in Mumbai, Vishwamdev Bhotica holds nothing back. He details the struggles with the pandemic and supply chain crisis, and talks about the various customers and the inherent challenges. He says "Today, a typical customer wants prompt answers, on-time delivery, and perfect quality – on repeat." To achieve this shift after shift, Sapco has educated their team members and customers about how files should be prepared to. Bhotica says, "We have created a training manual for everyone to go through. We keep adding information, however, it is never complete, and since knowledge absorption is never 100%. It's always evolving."

Sapco has 70% repeat orders. Bhotica says, "A typical order is received and expected to be output in its due course considering its process time." Today, the new factory is busy and it is converting paper/board, Kraft, metPET and plastics into numerous packaging formats such as cartons, labels, blister cards, and within cartons - window cartons, braille cartons, fluted cartons, stickered cartons, and many more specialised items.

For Bhotica, packaging means many things. He says, "popular opinion says packaging sells a product. But one needs to appeal to the buyer so that they wish to pick it off the shelves and convey the product contents to a buyer. And finally, it is all about safety to make sure it is safe from damage."

He warms up to the theme, and adds, "When you speak strictly of the process of packaging, yes it is the combination of pre-press, press coming together and creating a wholesome product that is worthy of holding its actual product. Packaging allows the product to speak to its audience and attract them into picking it up off a shelf/adding to the cart and facilitates a buying decision." And above all, each and every job has to be created with love and affection, says the packaging aficionado.

Cartons. That's the future of Sapco. Bhotica says, "Our vision is to be a one-stop carton packaging solution. Secondary and tertiary packaging is also being made by us." What are the plans for 2025? "Sapco aims to have utilised the current setup and possibly expand its footprint within this space either through more specialisations or with more product offerings," Bhotica signs off.

Vishwamdev Bhotica: The Music Man

What is your band called?

I am "in between" bands right now.

The number of shows thusfar?

Been a bunch over the last 15 years in college, with friends and with a few bands.

Describe your members and a typical jamming session?

Some chillers, some serious, the first few sessions have to be planned properly for a productive outcome.

Which was a breakthrough gig for your group?

Jazz (Not Just Jazz by the Bay)

What would be your dream gig?

Wembley Stadium.

Do you play only covers?

We cover mainly, but of late one of the bandmates has put out an album which we hope to play live soon.

Your top ten cult songs?

Green-tinted sixties mind.

Which rock band (living or dead) would you love to play the guitar with?

Guns N’ Roses.

What is the guitar you wield?

It’s a Fender American Elite Stratocaster.

Why and how did you select this axe?

Always wanted one since a while selection was through a lot of research.

How long does it take to prepare for a cover?

Depends on the day, if we’re serious or not.

Describe your favourite music gig?

I would classify the F16’s as a great gig scene in a club in Bombay. I would separate this from international band shows.

Rock N Roll or Blues?

Rock.

Opera or jazz?

Jazz.

Bhimsen or Dylan?

Dylan.

Who or what do you hate about the music scene in India?

Difficult to break through due to less awareness.

What is your favourite phrase in guitaring?

Riffs.

What is your favourite album?

Mr Big’s - Lean Into It. Any Guns N’ Roses album.

Who is the one living legend you would like to meet backstage?

John Mayer.

Live show or cut an album …?

Live show.

One show you attended which blew your brains away?

Mr Big – Bengaluru.

If you were invited to play at Wembley, what would you open your act with?

Welcome to the Jungle.

Other than the guitar, which music talent would you like to have?

Used to play a bit of the keys but lost touch.

Who would be your favourite party guests?

My friends, who else?

Where would you go if you could time-travel?

There’d be a long list of places.

Which song was your childhood obsession?

Sweet Child of Mine.

What advice would you give to your teenage self?

Should have started playing the guitar earlier.

See All

See All