Made in India: Flexgreen inline gloss coating – HRK9542

Flexgreen Inline Gloss Coating – HRK9542 is a UV LED coating for inline applications for gravure jobs, especially on paperfoil laminates substrate and laminated board for sheetfed printing, Rajesh Srivastava, VP, sales and marketing at Chemicals Business, Uflex, explains to Rahul Kumar

05 Oct 2020 | By PrintWeek Team

Flexgreen is the brand name for the LED product range offered by Uflex Chemicals. Uflex deploys UV LED curing technology with benefits of cost and performance. Energy-cured products are used in multiple application processes, including offset, gravure, flexo and screen coaters. Flexgreen Inline Gloss Coating – HRK9542 is a UV LED coating for inline applications for gravure jobs, especially on paperfoil laminates substrate and laminated board for sheetfed printing. This coating is based on a radical chemistry, which provides instant curing when passed through a UV LED lamp of 385 to 395-nm wavelength.

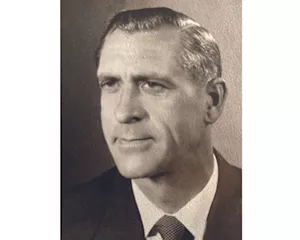

According to Rajesh Srivastava, VP, sales and marketing at Chemicals Business, Uflex, with major advancements in LED technology, today’s users of Flexgreen not only experience savings in operational costs but also have the satisfaction of using an eco-friendly product, compared to the traditional UV technologies. The chemicals division of Uflex was established in 1993. “The journey thusfar has been extraordinary,” says Srivastava. “We have driven this business with a single- minded focus on making the finest products available to the packaging community.”

Today, the company offers solventbased and solvent-less PU laminating adhesives, water-based laminating adhesives for paper/ foil structures, PU ink binders and flexo and gravure inks for high speed printing. It also offers a variety of primers, top coats, heat seal coatings, barrier coatings for PE replacements, water-based blister coatings, energy curable coatings, UV coatings, solvent-based matt and gloss coatings, UV LED coatings, water-based flexo and gravure inks, radiation curable inks and so on. “These solutions are suitable for both inline and offline applications, and are user-friendly,” he adds.

The coating The HRK9542 is a UV LED coating is applied to impart glossy and smooth appearance, apart from visual effects. UV LED coating offers a good processing, high reactivity and a good flow-out. It provides good mechanical/chemical resistance and enables clear and high-contrast images on a printed paper substrate through gravure process.

The HRK9542 was launched in the third quarter of 2019 from Uflex’s manufacturing facility at Noida. Srivastava says all potential gravure customers with jobs in paper foil for flexible packaging and metallised board for sheetfed printing use it for an added advantage of inline coating, which dramatically improves productivity. “We realise the cost pressures of our industry and so, we offer a superior import substitute at a very competitive price and performance,” he explains. “This being an inline LED coating, it helps save an extra pass (to do offline UV coating) and thus saves on machine, labour and opportunity costs.

"More than that, UV LED curing offers significantly lower operating costs compared to traditional mercury-based UV lamp due to energy savings, fewer consumable parts, and lower maintenance costs." UV LEDs typically use about 30-70% less energy compared to traditional UV curing.

Moreover, the operating life of traditional UV lamps is around 1,000-1,100 hours compared to LED lamps, which is at 20,000-30,000 hours. The coating is a combination of specialised oligomers, monomers and dedicated photoinitiators, which respond to this particular wavelength (385 to 395-nm) and then produces free radicals that initiate crosslinking with binders (monomers and oligomers) in a polymerisation reaction. This formulation also incorporates some additives to impart slip, stability and resistance properties.

The market

“In India, we have met with significant success in almost all key markets, including Kanpur region, Delhi-NCR, Hyderabad and Bengaluru. As regards to exports, we are in an advanced stage of product’s trial and approval and plan to begin our exports soon,” Srivastava says. He adds that for a product like this customers usually look for product availability, cost effectiveness and of course, consistent performance at a high speed. Clients do expect an excellent on-field technical support.

The USP

Srivastava says the USP of this product is its ability to be used inline at a high speed on a gravure machine. “With conventional UV coatings, this was unimaginable due to fire risks and curing limitations, but the introduction of this product has successfully dealt with those challenges,” he adds. “It is a cost competitive solution for an inline LED coating for paper foil flexible converters and metallised board for inline sheetfed offset printing and coating. Compatible with 385 to 395-nm wavelength LED lamps, it can run at high speed up to 350- mpm. Plus, it’s emission-free.”

He adds that the coating offers excellent curing, gloss and smooth appearance, low odour and above all, it comes with legacy and expertise of Uflex Chemicals for an excellent on-field technical and application support. He says currently, only few suppliers are importing similar products from their parent companies in Europe. Uflex Chemicals is the first producer of such coatings in India.

The usage

Srivastava says UV LED offers many advantages, including significantly longer life times, consistent output, more energy efficiency, no ozone emissions, no mercury wastage, much less heat onto substrate and instant on/off technology, which can reduce further the downtime required in waiting for the lamps to come to full power. “There will be an obvious increase in productivity as one saves a complete process of an offline pass, thereby achieving higher machine speed, less wastage, labour cost besides reduced power bills.

Overall, it’s a win-win situation for customer with huge productivity advantage,” he adds. As far as customer service is concerned, Srivastava says, Uflex is committed to its customers and is determined to make their processes easier, simpler and cost-effective. “We offer 24x7 on-field technical support besides product and application related training,” he adds. Looking ahead, Srivastava says as Uflex is amongst the first few manufacturers to introduce UV LED solutions for printing and packaging industry in India, the motivation was to address product availability and cost issues associated with this new generation technology.

“Currently, we are offering complete range of process colours, base colours and coating range, including texture solutions/ speciality coatings such as glitters for offset and narrowweb applications,” he concludes.

See All

See All