Two CTP installations for Kodak

Kodak installed a CTP system at Saraighat Offset Press in Guwahati. The company has opted for a Q800 Trendsetter in a move to improve the speed and productivity of their pre-press operations.

14 May 2015 | By Anand Srinivasan

Bhargav Bharadwaj, partner at Saraighat Offset Press, said, “With the new Trendsetter equipment, we have improved our management of dot gain. This was very important to us since we produce high-quality covers and brochures. Now, we can deliver top notch output with sharper and brighter images.”

According to Bharadwaj, the new Trendsetter will constitute nearly 80% of their plate-making requirements.

The new Trendsetter will run Kodak’s process-free Sonora plates. This combination, Q800 and Sonora plates will totally eliminate the processing step required by traditional thermal plates. “Subsequently, providing significant energy, water, and waste reductions, without making sacrifices on productivity or print capabilities,” added Bharadwaj.

There are plans for Saraighat to also integrate Kodak’s Prinergy workflow, to streamline the operations.

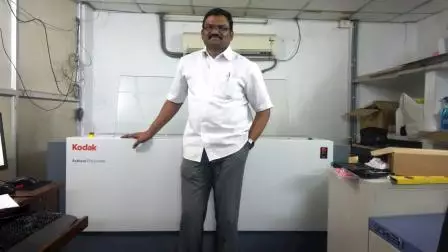

The second install for Kodak is at Sai Likhita in Hyderabad.

This commercial and publishing printer has installed Kodak’s Achieve platesetter. This will replace the old platesetter. “The old platesetter was becoming a drag on the operations productivity, delivering slow output speeds of six plates per hour,” said Venkateswara Rao, proprietor at Sai Likhita.

This commercial and publishing printer has installed Kodak’s Achieve platesetter. This will replace the old platesetter. “The old platesetter was becoming a drag on the operations productivity, delivering slow output speeds of six plates per hour,” said Venkateswara Rao, proprietor at Sai Likhita.“With the new system in place, we are now able to produce five times as many plates per hour of the same size while delivering high image quality with excellent reliability and consistency,” he added.

For a company that produces over 200 printing plates in a day, the Achieve platesetter has helped reap big improvements across its entire operation, in combination with Sonora process-free plates.

“Not only have we improved productivity with quicker outputs, but there is also a considerable increase in image quality that we can deliver now. Adding to this, Sonora has eased out our operations where the imaging output matches that of the mainstream processed plates,” concluded Rao.

See All

See All