Ahmedabad’s Amba hails diversification to tide over crisis - The Noel D'Cunha Sunday Column

Rising cost. Falling margins. Dwindling runs. With so much gloom and doom in the print circles, it’s a wonder how print firms are successful. Amba Multiprint is one of the hundreds of printing businesses that are not just surviving but thriving. Noel D’cunha finds out

11 Jun 2023 | By Noel D'Cunha

Amba Multiprint (formerly Amba Offset) started in one printing business segment but diversified into new product lines and segments. Today, Amba Multiprint has the capacity to produce 175-million labels per month. Ankit Mehta, a management team member at the Ahmedabad-based group, says, “In five years, we established a successful label division. Today, the packaging and label division are equal, and so is the turnover.”

Amba Multiprint has a history of diversification. In early 1998, Amba catered to commercial printing products in Gujarat. It set up a production unit in a 2,000 sqft rented premises in Ahmedabad. It was engaged in producing commercial prints like books and brochures. “There were ups and downs,” says Ankit Mehta. “But with the arrival of advanced binding machines and a Dominant two-colour offset press, we turned less into more. We printed many more products.”

The turning point was two decades ago. The period 2005-10 saw Amba Multiprint expand its business with more in-house facilities after adding a single-colour Heidelberg SORD and a four-colour Heidelberg MOVH press. By 2015, the company became one of Ahmedabad’s leading offset printing presses. “We grew, and we expanded. We added another rented facility of 2,000 sqft, dedicated solely for binding,” says Mehta. A year later, it decided to move out of Ahmedabad to a bigger site in GIDC industrial estate in Gandhinagar, where it purchased land for an 18,000 sqft facility. “With the move to the new facility in Gandhinagar, we were a complete in-house commercial print service provider,” explains Mehta.

Ankit Mehta, management team member at Amba Multiprint

The move to packaging

By 2015, the internet and digital impacted the print P&L. The commercial printing business started plummeting during this period. While Amba did all kinds of printing – books and commercial print works like brochures, magazines, diaries, calendars, leaflets, and flyers, it was commercial printing, which was a big part of its business. For example, Mehta says, the print runs reduced – from 5,000 brochures, it came down to 500.

“We started to feel the heat,” says Mehta. “We had employees working with us since 1998, and we had to get past this crisis of reduced volumes to survive, which we saw coming.”

Packaging was the way ahead for Amba, but it was the other end of the print spectrum. “We were like a sailboat where steering it with commercial print business would be counterintuitive. We had to push the tiller the opposite way if we wanted to go forward,” explains Mehta.

Taking advantage of new opportunities would mean a change in thinking, which often requires a complete cultural change. “Key to our growth has been how we defined our company – we are not what we make, but what we do,” says Mehta.

With the move into the new facility in 2016, the management team started planning Amba’s segment-shift strategy. It involved diversifying into packaging, emphasising emerging products.

In 2017 and 2018, Amba started two new divisions – carton packaging and labels and shrink sleeves.

It replaced some of its older presses with a secondhand Komori L628, a six-colour plus coater press. The company initially did small-quantity packaging jobs, which were finished on manual punching machines. As the packaging business picked up, it started taking up metallised printing, giving it a big fillip. It then invested in Excel Machinery’s Maxima semi-automatic die-cutting machine plus one more automatic die-cutting machine.

Boom in business

By the end of 2018, Amba’s packaging business had gained momentum, and it had posted revenue growth.

The progress the group made in the packaging segment did not by any means deter the company from continuing with its commercial printing business. It continued to be its first choice in the printing business. “Even today, it is more profitable than our packaging business.”

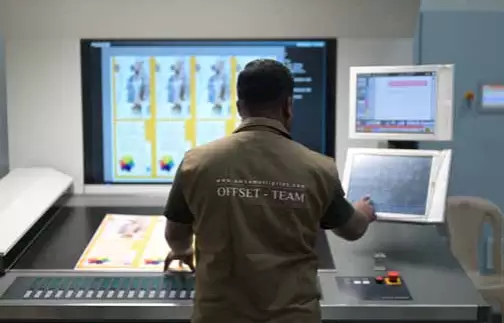

The Komori Lithrone G37 is fitted with PDC-SX spectral density control system for print quality control

Despite the reduced volumes, how is commercial printing still profitable? Mehta explains, “We are printing the 500 brochures or catalogues at the same cost we would have charged for the 5,000 copies. But now we are using less material and labour. Therefore the profits are bigger.”

Also, commercial printing has become premium. In the 1990s, brochures would be centre-pinned. Then came perfect binding, and the spine was altered. In the 1990s, people wanted hardbound book covers, but the cost hindered its growth. “Now hardbound books are back in vogue, and binding has become premium, fetching more profits,” Mehta explains.

Besides, Mehta says Amba is using some of our finishing technology for commercial print jobs for packaging – for example, folding leaflets supplied with cartons or even rigid box manufacturing. “So yes, some commercial printing technology is being used in packaging too.”

For print-on-demand jobs, the company deploys the Xerox Versant 180 digital press.

“This balance of commercial and packaging has worked well,” says Mehta.

Labels within the packaging business

Its labels and shrink sleeves foray began with Multitec’s flexo press, S1 with delam and relam, Weigang WQM 420 die-cutting, and DK 450 slitting machine. As it progressed, it added Rhyguan die-cutting, and sleeving inspection machines.

Amba ventured into the labels and shrink sleeves business because of the limited funding resources to expand its packaging business. The Komori L628 was a smaller-sized press. It became an impediment to packaging jobs.

Mehta explains, “If we had to expand our packaging operations, we would have to invest in a bigger press, say a 25x36inch or a 28x40inch size. We did not have that kind of resources for the investment.”He further states, “Our investment pattern has always been gradual but steady.”

The company had Rs 2.5-crore as funds for expansion, and with that kind of budget, it could only invest in a label making unit. That’s how it opted for a Multitec flexo press and Weigang finishing kit. “We couldn’t afford a Gallus. The only Indian flexo press manufacturer was Multitec, which had acquired an international reputation by then,” says Mehta.

The Komori Lithrone G37 at Amba can run at a maximum speed of 15,000 sph

New business, new challenges

How did Amba transition from packaging to label? “Everything was part of the learning curve. We were printers who knew offset technology. We had no knowledge of flexo, flexo cylinders, or flexo plates. Die-punching was different. For one year, it was a struggle.

Plus, about five or six big converters in Gujarat were so big that we couldn’t approach them directly. So, in a way, it was a struggle,” says Mehta.

But it found help from his suppliers. “We bought the flexo press from Multitec. Amit Ahuja of Multitec supported us with training, Weigang die-cutting representative in India, Pinkesh Shah, director, Global Graphics Machineries, extended help. Our customers were supportive. The volumes were less, but there were more SKUs. The big converters could not supply the labels on time. We could do this, even though we were facing some issues or the other. But slowly and gradually, we found a way,” says Mehta.

The initial stages of the label and shrink sleeves business were a struggle. How did Amba manage to stay afloat? Mehta explains, “Initially, the labels division wasn’t making profits. In fact, we weren’t making money from the label work. We had to dig deep into the profits from commercial and packaging divisions to stay afloat.”

Is running a business from other business verticals’ profits a good idea? “Yes, as long as your other businesses are reaping benefits. Our experience says that the new business should become independent within six months to one year and start making profits. If one does not have deep pockets, venturing into a new business without any financial backing or a parallel business which is doing well is not a good idea. It is fraught with danger.”

The six-colour plus coater Komori Lithrone GL37 press at Amba

Meanwhile, Amba continued to boost its label’s arsenal. It installed a Jetsci Global Colornovo hybrid digital label press. “We needed a solution allowing us to work on various substrates, such as shrink sleeves, IML, and lamitubes. We decided to opt for an India-made Colornovo hybrid press with a UV dryer and chiller plates under every printhead. This gives us production to run many heat-sensitive materials.”

It was a good move. Production was on the up. The company ordered its third Multitec flexo press, a 10-colour press, which will be delivered soon.

A plant backed by a Komori

With the commercial, packaging, labels and shrink sleeves businesses growing at a CAGR of 55%, Amba set out looking for a plot that would hold all three businesses and their growth.

The Amba team identified a plot in Chattral. It began the construction of the 1.70-lakh sqft facility. “We started the construction work on the new plant in 2020, in the middle of Covid-19. We faced challenges – escalation in cost due to rise in steel prices, but by May 2022, we had moved our warehousing and packaging divisions in the new plant,” says Mehta.

The first new installation after Amba partly shifted to the new premises was the Komori Lithrone press – GL37 six-colour plus coater. The GL37 press arrived at the plant in March 2022 and was installed in the next two months.

Since Amba had poured its finances into the plot and construction of the new facility in Chattral, the initial plan was to invest in a secondhand 28x40 press. The search for a secondhand press, which was a five- to six-year-old press came a cropper. “We did not want to invest in a 20-year-old press. The ones we examined would cost us less than a new one would. So, we decided to buy a new press.”

Mehta had zeroed in on the Komori Lithrone G40, but settled on the GL37 as 95% of the jobs fitted well in the 28x37-inch format of the GL37. “We also read the news stories in PrintWeek magazine, where Pragati Offset in Hyderabad and Vijayshri Packaging in Indore invested in the GL37. We read that Vijayshri added a second GL37 press to its portfolio. On cue, we consulted a few industry experts who suggested we invest in a GL37,” explains Mehta.

The new GL37 replaced the company’s older Komori L628 press. “While we utilised the press for our packaging work, we faced issues running thicker paperboard such as 350- to 400-gsm paperboard. Some of the issues were guard marks and the curling of sheets.

Amba’s 200+ strong workforce

This would result in avoidable wastage. Though our customers were not very demanding, we did not want to continue with the way we did our jobs, plus we wanted to arrest the wastages,” says Mehta. Besides being an older press, the L628 did not have as many features as one would want in today’s time.

The Komori Lithrone GL37 at Amba can run at a maximum speed of 15,000 sph. It is fitted with benderless full-APC (fully automatic plate changer) and technology that shortens makeready time and quality control such as the PDC-SX spectral density control system.

The company runs the press at a speed of 13,000sph to 15,000sph as compared to 11,000sph to 12,000sph we ran on the L628. “Besides, there are productivity gains as well as profitability arising from the speed, makereadies, quality and consistency. While we can easily pass off sheets twentieth onwards as saleable, we still let go of a few sheets. These sheets are, of course, used as trial sheets while finishing,” says Mehta.

With the GL37, Mehta says, his company has completely eliminated the print blemishes. “Our wastages in terms of initial runs too have come down by 75%. This has boosted our profit margins,” adds Mehta.

Slow and steady

Amba’s approach to investment has always been slow and gradual. “We take smaller steps. We build from a small base. And then, we take bigger leaps. This is what you can call – one day at a time approach. We invest in a technology that is not too costly, get hands-on with it, and go bigger,” says Mehta.

For example, SAP was Mehta’s ultimate goal. But he wanted his team to be ready, before he implemented SAP for its process system. “Implementing a system like SAP is a habit. There is a chance of failure if the entire team is not on board. Hence, in the interim, we implanted ERP software for our backend production operation. We have good results. In the next few years, we will implement SAP in our plant.”

Mehta says that things have changed quite drastically in the last two decades. “If you were a printer, you were a king. It’s not the case now,” says Mehta. But he thinks there are two things that will help you grow in these changing times – your suppliers and your employees.

Pay your suppliers in time, and they will be happy, Mehta advises. “If you don’t, you and your staff would always be looking for new suppliers, which is a waste of time, for no returns. Plus, you will get the best prices for your raw materials,” he says, adding, “Take care of your employees too. There’s no substitute for a loyal employee eager to help grow your company.”

See All

See All