Art Next: Unfolding a brand new set of ideas - The Noel DCunha Sunday Column

There are over 1,00,000 startups, with many of them operating in the FMCG and food sectors, and all of them are looking to establish a unique identity for their products. With a set-up equipped with the HP Indigo 25K, Navi Mumbai’s Art Next is creating a niche for boutique brands with its flexible packaging solutions. Noel D’Cunha and Aditya Ghosalkar find out. Read more

03 Feb 2024 | By Noel D'Cunha

Tucked between Thane and Navi Mumbai, the Art Next plant is at the forefront of flexible packaging using digital printing technology. As founder and director Amol Lambe says, “We look forward to taking the idea of flexible packaging to the next level by bringing in digital printing as a revolutionary alternative to conventional processes of producing flexible packaging.”

What makes Art Next’s endeavour successful is how it has efficiently responded to client demands through experimentation and creativity with high-yielding and quick-quality packaging solutions. Art Next’s venture encompasses pursuing new markets, new technologies, self-directed work teams, lean manufacturing and an emphasis on safety.

The bulk of Art Next’s production is flexible pouches under the brand Nexibles (derived from their belief in next-generation flexibles). But the flexible packaging business supersedes Lambe’s journey in managing a pre-press unit. He says, “Never did I imagine I would venture into this space without knowing the ‘f’ of flexible packaging.”

For that decision, the business plan required a whole series of changes, from technology to operational standards to the layout of a state-of-the-art facility.

How it started

Working in the print industry runs in the Lambe family. His grandfather, Keshav Lambe, owned Vishwabharati Printing Press, which used treadle print technology. However, this technology eventually became obsolete, resulting in the family embracing new technology. Lambe’s father, Suresh Lambe, who had retired from Metal Box, founded Amol Graphics. The company then specialised in hardcore carton pre-press and photolitho operations involving negative, positive, and bromide preparation. Thanks to his father’s expertise, the business gained jobs and customers. Amol Graphics has offered pre-press solutions to India’s leading print and packaging companies for almost two decades.

Over the years, the manual and time-consuming chemical processing involved in making plates from the film has been replaced by CTP. “It was the digital replacement for the manual, time-consuming chemical processing that is performed when making plates from film. It was a game-changing process, and that was the time when I decided that digital would be at the core of everything I do,” says Lambe.

And so it was. Art Next is a digital solutions company that prioritises prompt service and rapid turnaround time.

Art Next began its digital journey with a global coffee company. The company urgently needed stickers for its just opened outlets. “It was a just-in-time approach,” explains Lambe. We had to deliver stickers in 18 hours.”

This global coffee brand is an SOP-driven corporation with over 37,000 stores worldwide. Art Next supports them with over 2,000 articles, including menu boards, banners, and tissue paper. Initially, Art Next operated as a sticker manufacturer for their requirements. It was achieved with a Canon sheetfed press, which was later deployed to produce small-run jobs such as brochures, flyers, and food tags.

Art Next manufactures over 1,900 items, supplied to nearly 400 outlets, which translates into scores of SKUs. To meet this demand, there is a dedicated floor with a team of around 35 persons. A dedicated space for its production activities ensures crisp operations and agility.

A team of 35 members on the shopfloor

Aquisition of HP Indigo 25K

Over the past two decades, Art Next has partnered with multiple fast-paced segments in retail and food and beverage (F&B) for its print and paper-based packaging requirements. Then, the proposition expanded to include a flexible packaging portfolio.

To share some data, from 450 startups in 2016, there are well over 1,00,000 start-ups in 2023. Further, the FMCG market reached USD 56.8 billion as of December 2022. The total revenue of the FMCG market is expected to grow at a CAGR of 27.9% through 2021-27, reaching nearly USD 615.87 billion. Indian food processing market size reached USD 307.2 trillion in 2022 and is expected to reach USD 547.3 trillion by 2028, exhibiting a growth rate (CAGR) of 9.5% during 2023-28 (data courtesy: ibef.org).

Art Next has serviced the flexible packaging needs of over 500 start-ups in its two-plus years of operations.

Lambe says the Indian packaging industry focuses on big brands, with big volumes and larger runs. “The digital sphere strikes a direct conversation with owners of the brand, primarily start-ups, who are looking for attractive packaging in smaller numbers to compete in the retail space.”

Although companies equip a combination of digital and conventional machines to meet different objectives, Lambe says, Art Next’s focus has always been on digital. “The conventional process depends on auxiliaries including plates and dies. With digital, there is no need for plates as required for flexo printing, and or cylinders required for gravure printing. Digital offers a quick turnaround time and is a game-changer when the need for customisation arises.”

The move to flexible packaging production required the introduction of printing equipment designed for a limited number of products but with larger SKUs. Hence, in November 2022, ArtNext installed the HP Indigo 25K digital press to address the on-demand flexible packaging market. This scaled its packaging business by providing flexible digital packaging solutions like pouches, shrink sleeves, labels, and roll stock laminates.

Lambe shares an example from his childhood to explain the influence of digital. “Back then, photo studios charged Rs 20 to Rs 30 for around 15 photographs, which took at least a week to deliver. Now, the price has surged ten times for just five copies, and the prints are instant. That’s the change digital print has brought.”

With optimised production and cost efficiency, HP Indigo 25K has enabled Art Next to manage high-volume customers and deliver any job of any size on time. With up to seven colour stations, HP Indigo presses allow variance in the colour sequence and enable the addition of multiple passes or ‘hits’ of the same colour to increase opacity or achieve special effects.

But is digital printing cost-effective while competing in the flexible packaging market? “Certainly,” says Lambe. Our minimum order quantity is 500 packs. We offer a flexible pouch that packs products worth Rs 60 to Rs 80 at Rs 7 per pack. These products are then sold in retail at Rs 180 to Rs 250. It offers sustainable profit for the startups while creating their brand presence.” Thus, in 2021, the brand Nexibles was born.

The minimum order quantity is 500 packs

Democratising packaging

Technological limitations about toolings and minimum order quantities made flexible packaging available only for big players such as Nestle, Mondelez and the like. It is these big brands that the converters with conventional technologies service for longer runs. It makes operational sense. However, the tooling cost of plates or cylinders associated with conventional methods of printing and related minimum order quantities (MOQ) makes shorter runs expensive.

This is where the small brands with smaller requirements suffer. Small brands face this problem, plus the selection of substrate and design. “With our goal of democratising packaging, we empower start-ups and small brands to stand out on the shelf. Nexibles will always have this principle at its core,” says a brimming Lambe.

He explains that, primarily for food packaging, there are four to five samples of different sizes, such as 75-100 gms, 100-150 gms, 200-250 gms, and 500 gms. “With a minimum order quantity of 500, the pricing for these is Rs 7, Rs 13, Rs 15 and Rs 18.50. Again, this yields sustainable profit to our clients while strengthening their brand image.” He goes on to explain how they designed a solution catering to the specific short-quantity needs of these aspiring brands. “Nexibles offers a unique solution called Nexi Classic. This is tailored to accommodate requirements across predefined pack sizes that most brand owners could adapt their packaging to. A structure was designed for each of these sizes, offering a unique blend of aesthetics to the pack while offering excellent barrier properties to the product. Today, Nexi Classic is a hot favourite with most of our clientele and we are looking at adding newer sizes in the current period.”

Does Art Next limit itself to just print and package production? No. Smaller brands and start-ups often lack quality designs. An in-house team of designers ensures that Nexibles becomes a holistic solution for all those who seek it. A special mention of a key design team member needs to be made here. Niranjan Ranade is a differently abled design team member with a unique hearing and speech impairment. “His ability to communicate through his work easily outdoes his challenges. A fact that ArtNext is a platform for such talent to prosper, speaks volumes of the work culture the company breeds,” says Lambe.

Print and quality consistency

Brands that are stringent regarding colour consistency and quality issues can rely on the 25K press, says Lambe. The 25K uses liquid electrophotography (LEP) technology and can match Pantone colour automatically within minutes using a proprietary technology called Spot Master. He explains, “The inks used by HP Indigo comply with the FDA and EU’s food packaging regulations. They are free from UV monomers and harmful VOCs. Additionally, these inks meet non-migration standards, which make them safe for use in food and pharmaceutical packaging.”

On the sustainable front, digital is favoured over any conventional method; plus, the new generation demands sustainable offerings, says Lambe. “A pouch printed on digital over conventional will result in a considerable reduction of 60 to 70% CO2, water, electricity and VOC. This keeps a check on the environmental footprint,” Lambe explains.

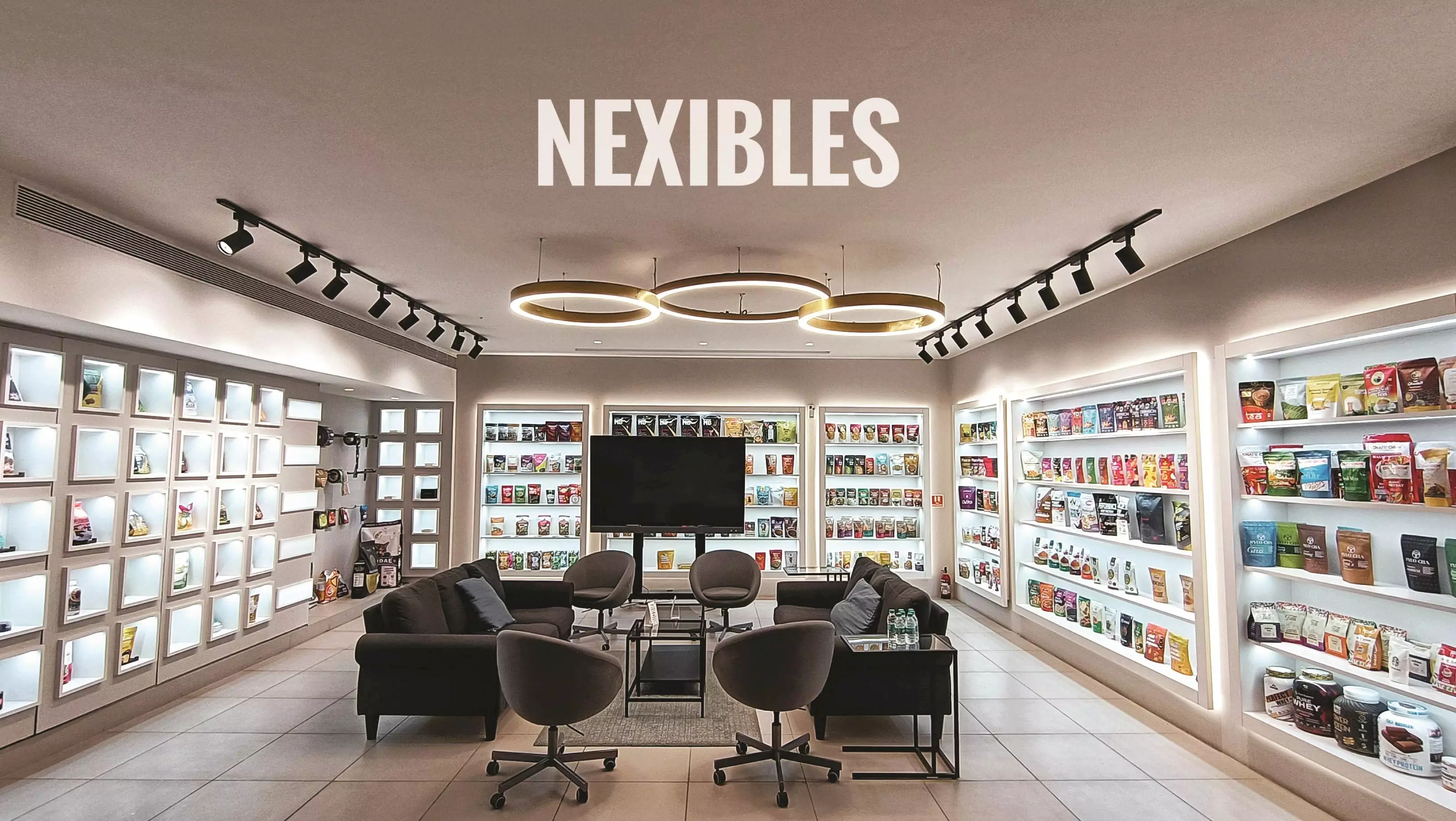

And there is more. Art Next has an experience centre within the production plant. “When brand owners visit our experience centre, we let them spend time in silence in this space. No commercial discussions are carried out until the visitors have absorbed all that is on display. This exposes brands to the limitless possibilities of the digital flexible packaging space.”

Art Next’s experience centre

Navigating through material choices

In its internal research, Art Next found that a substantial percentage of today’s consumers seek greener alternatives. The research also revealed that brand owners want to make a conscious choice and put conscious effort into their packaging. On the sidelines, the same number is associated with the preference for a matte look over glossy, in commercial packaging.

Around 90% of manufacturers use MetPET or BOPP film, and Art Next is collaborating with a materials expert to produce sustainable material. “As a converter, we would offer the brands the choice to opt for sustainable or metallised options,” says Lambe. “You choose the least evil as an option. Why waste metallised media if the customer doesn’t need it? Brands or buyers can advocate a choice of inks and materials.”

To explain this, Lambe shares an example of a start-up brand – Shaka Harry, a plant-based meat brand. The packaging contains frozen food. “The packaging is 100% recyclable, eliminating metal usage.” He adds, “There is a need to educate the buyers. It is the call of the brands to opt for sustainable packaging, which may be expensive given the use of complementing metallic inks.”

Power to people

The success of Art Next has rested not just with top management but with a flexible workforce. The last few years of the journey have been focused on creating a culture in which the employees are empowered and encouraged to identify continuous improvement opportunities.

Lambe explains, “At Art Next, continuous training is essential to professional development. It involves providing employees with ongoing education and learning opportunities to improve their skills and knowledge in their respective fields.”

For example, Pramod Jadhav started as a driver at Art Next in 2016. His curiosity about printing equipment and processes led him to question colleagues on the production floor. He was particularly interested in the HP Indigo 25K digital press. “He held the keys to the company’s vehicles. Today, after being recognised for his work ethic, character and curiosity for manufacturing, he has been trained by our team and today is promoted to a press operator,” says Lambe.

Art Next’s culture is built on the spirit of equality and camaraderie. Jadhav and Ranade signify a key to the company’s growth.

Employing differently abled individuals is also part of Art Next’s social responsibility. Lambe says, “We believe that it is an important step in contributing towards creating a more inclusive society. The company benefits from the unique skills and perspectives that these employees bring to the table. It is a win-win situation that promotes diversity, inclusivity, and

accessibility in the workplace.”

So, what’s next for Art Next? Lambe mentions the company’s goal to purchase a new machine. “Working with HP is like having a business partner that supports you on not just setting up of plant and machinery but also other important things like business development activities, and new application developments. Our immediate plan is to add another Indigo press in the coming months to support our growing business.”

He concludes, “Besides, we are developing an app to provide a platform for brands to communicate with us.”

ArtNext Factfile

- Established in 2006

- Location Navi Mumbai

- Speciality Flexible packaging, design, cafe in-store brand communications, fit-outs, digital displays, digital menu boards.

- Equipment HP Indigo 25K, pouching machines, combi lamination machines and other ancillary machines.

- Employees 84

See All

See All