Avantika’s new service for digital presses - The Noel D'Cunha Sunday Column

It's all happening at the Avantika factory in Greater Noida. The aim is, to make life easy for customers who can take advantage of the Ghent PDF Output Suite 5.0 Conformance Certification as well as the digital printers that deploy EFI Fiery digital front-end (DFE) print servers.

In this Sunday Column, Himanshu Pandey describes the process to Noel D'Cunha of PrintWeek

14 Aug 2022 | By Noel D'Cunha

Himanshu Pandey, director at Avantika Printers, says, “This is a certification for our print unit. It tells the customers that the unit is ready to accept the PDF/X-4 standard files. The type of input which the designer has created for the brand is reproduced as it is without losing any data.”

The new certification offering uses the PDF test suite from the Ghent Workgroup (GWG). It enables print and packaging companies to easily prove they can print PDF files correctly and, therefore better promote themselves as a partner of choice to existing and potential customers.

Once certified, the print firms receive a digital badge to show their PDF output workflow is compliant with the PDF/X-4 standard (ISO 15930-7:2010) for use on their website and for other marketing purposes. Certified companies also have their name and location displayed on the international Ghent Workgroup site.

Himanshu Pandey adds, “Currently Indian print professionals are using stock PDF settings which were designed for general purpose. The PDF/X standards have standards for the print industry. The problem is, most Indian pre-press houses are still using PDF/X-1 as a benchmark. But now the digital engines are much-more robust and are capable of handling complex files with ease. So instead of losing data while processing, the files can be easily processed.”

He continues, “Print producers are very familiar with conformance to colour standards and what that means in terms of expected results, happy customers, and reduced waste – the interpretation of PDF files needs to be thought of in the same way, it’s equally as important.”

The data, which Himanshu Pandey is referring to, is known as colour data (RGB, CMYK, Pantone) in the same file, transparencies, vector elements, layers, and fonts.

EFI and Ghent partnership

EFI has partnered with the Ghent Workgroup for this service.

In real terms this means that on the latest Fiery DFEs, setup for certification and ongoing conformance takes seconds, unlike competitive solutions. VP of sales and marketing John Henze of EFI Fiery told PrintWeek, “Plus, we’ve made this service very easy and very affordable to encourage Fiery DFE users to take this important step to higher quality, and more reliable prints.”

The steps to achieving the certification are said to take under an hour. Print businesses that use EFI Fiery DFEs on their digital equipment for cut-sheet or wide-format production can order the certification service from EFI by filling out an online form.

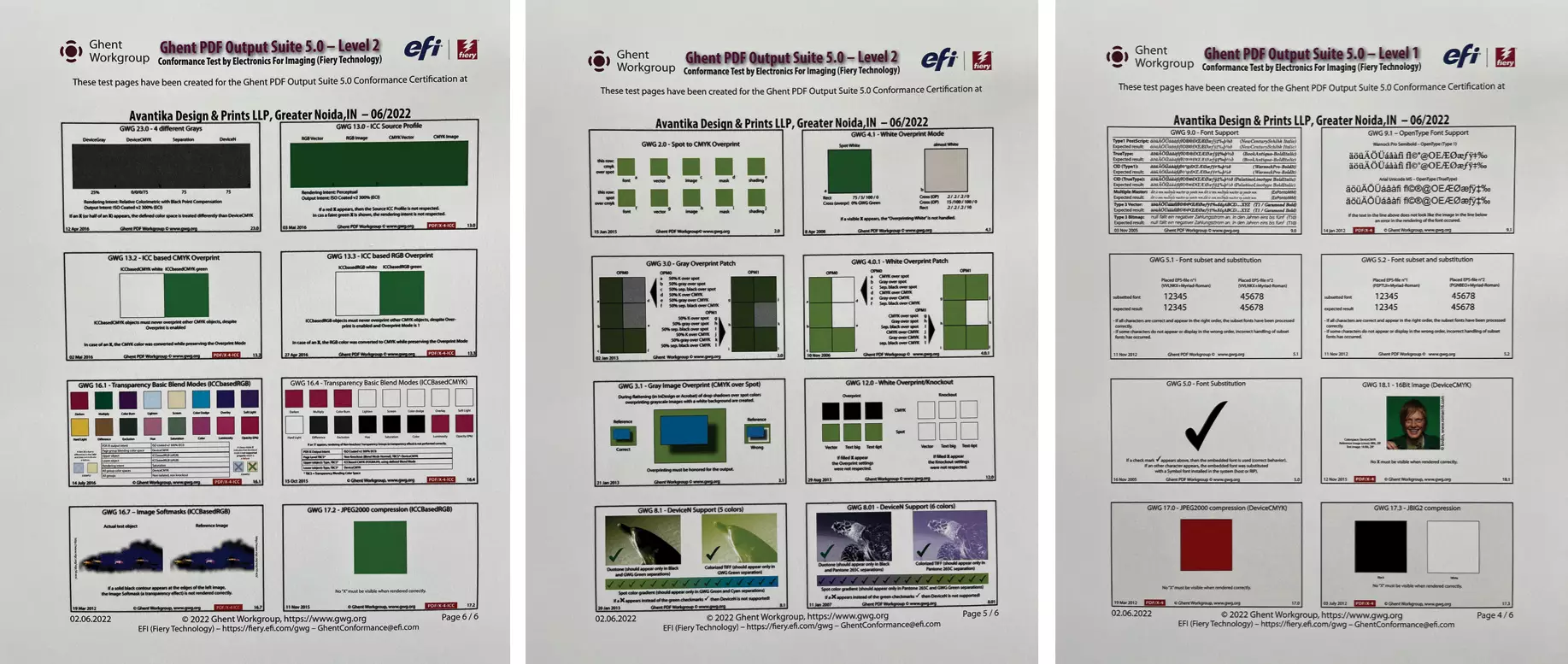

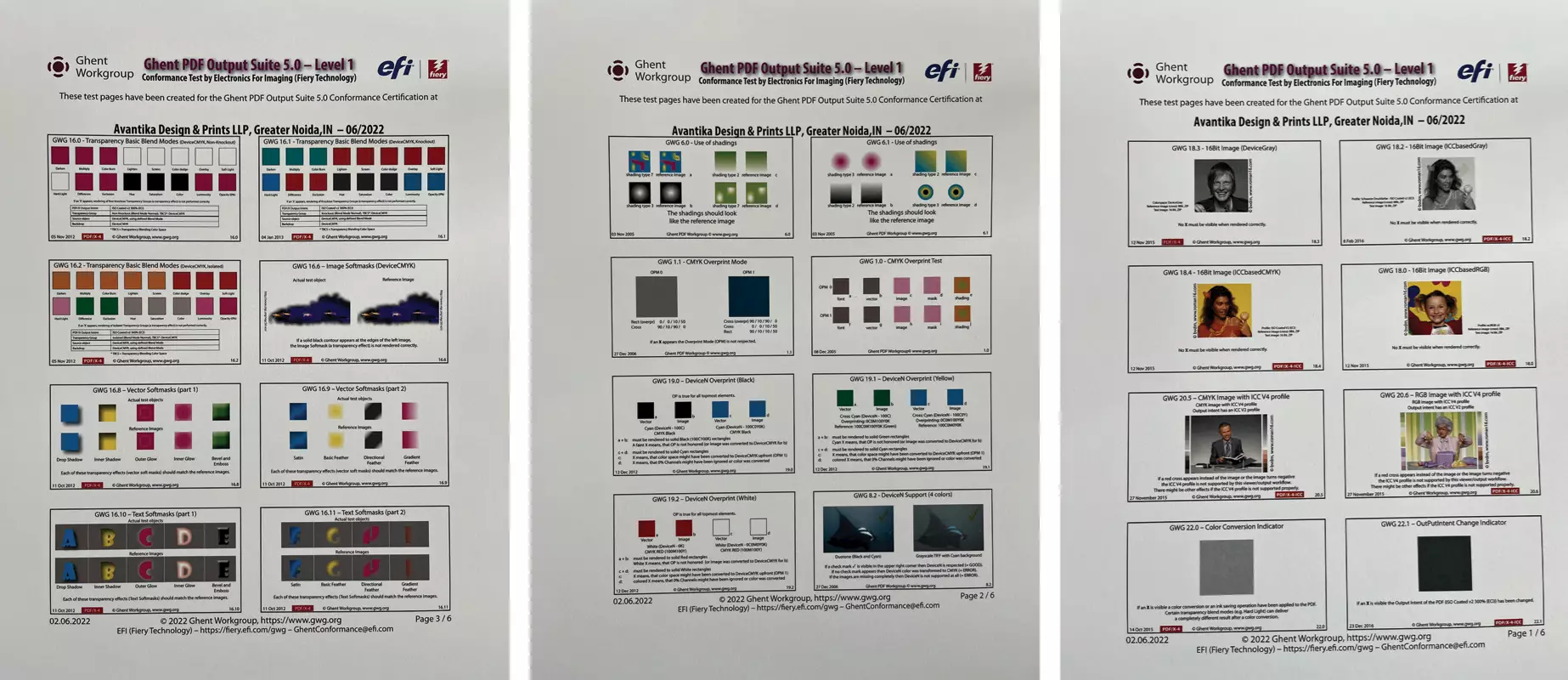

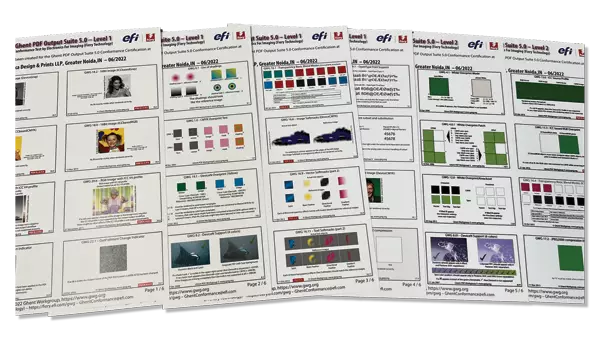

EFI then electronically sends personalised Ghent Workgroup test forms along with a short video on how to set up their Fiery server to achieve a pass.

Once they print the forms, Fiery users can take photos of their output using a smartphone and transmit the images to EFI for evaluation of each test element required for certification. EFI and the Ghent Workgroup can complete the certification within a week of receiving the output photos.

EFI said Fiery DFEs are designed with the ability to easily create the correct PDF/X-4 output required for Ghent PDF Output Suite 5.0 Conformance Certification.

It said that on the latest Fiery DFE platform for cut-sheet printers, generating certification-compliant output only requires selecting a single checkbox in Fiery JobExpert, EFI’s technology for automated optimal PDF print production.

“We are delighted that EFI is joining us in this effort. The test form consists of six pages, and especially with the newer generation of Fiery servers, EFI has made it easy to submit and print them,” said GWG chair David Zwang.

Himanshu Pandey concurs, “Once approved, the certification is valid for two years and can be a key differentiator for print and packaging service providers as they continue with existing customers and work to gain new ones – especially in a highly competitive environment where customers are increasingly focused on the quality of their printed products.”

He says, “I opted for this for my Greater Noida unit as I wanted to focus on packaging. As you are aware, the packaging files are more complex and feature-rich as compared to the commercial print segment.”

Being agile

Avantika Printers began its journey in 1988. Its digital print centre is based in Okhla Industrial Area in Delhi. Honoured with the Best Digital Printers PrintWeek Award consecutively for three years, from 2011 to 2013, the company’s focus area is to produce niche packaging. A family-owned business which is professionally managed, by Mukt Nath Pandey and his two sons. Himanshu Pandey (elder son) is responsible for automation and

quality; and Krishan Pandey is responsible for marketing and clients servicing.

For the past few months, the Pandeys are setting up a vertical in labels and packaging in Greater Noida. Himanshu Pandey says, “The set-up is taking shape and a new team will be stationed at that unit. We will be ready to work by the end of this year.”

Mukt Nath Pandey (director) says, “It can be labels and boxes especially related to marriages, where we have planned to set up a niche but perfect solution for small quantity jobs.”

MN Pandey explains, “Outer packaging will increase and individual packaging will decrease in the consumer items. Direct printing on the boxes will be increased. Also with the central government ban on usage of single use plastic, sustainable packaging will see a huge demand.”

MN Pandey adds, “To guarantee quality, cost effectiveness and productivity, press automation is required. From pre-press to finishing. Customers should be aware about each and every operation of their jobs. It will help to communicate better and increase business.”

Faster proofing

Dibyajyoti Sarma, who is associate editor at PrintWeek and publisher at Red River is a happy customer at Avantika. Most of the Red River publications are produced at Avantika. Sarma says, one thing people should know about Avantika is, “The colour controlled lighting, plus optimum environment for printing in terms of cooling and humidity.” He adds, “The Avantika team works with numbers. This means, zero compromise and faster turnaround for jobs.”

MN Pandey says, “Quality is a niche which everybody tries to achieve but to get it consistently and job-on-job is quite a challenge. The client’s expectations is what Team Avantika tries to make our daily jobs. We ensure this sans hiccups. We try to understand what the client wants and his/her expectations can be matched or exceeded at the Avantika unit without much deviation.”

He adds, “Nowadays apps are available whereby you can check the soft proof on your smartphone, give green signal and get real time delivery. This facility is available in the print production units where workflow is in place.”

Himanshu Pandey says, in this day and age, one must understand what the customer’s needs are. He says, “As per my client’s requirements, searching for new machines which can co-work with my existing infrastructure.” Current example is an iEcho machine for sampling and low production.

He concludes, “Most important is making customers understand the file format required to suit for print output envisioned by them at their place. Such as getting files from them in the PDF/X-1 format remains a challenge. Therefore, by adhering to this certification we are working with them to make them understand how these files affect the output and what benefits they are getting in return.”

See All

See All