Day two of Heidelberg Innovation Week: How to use the data in the right way

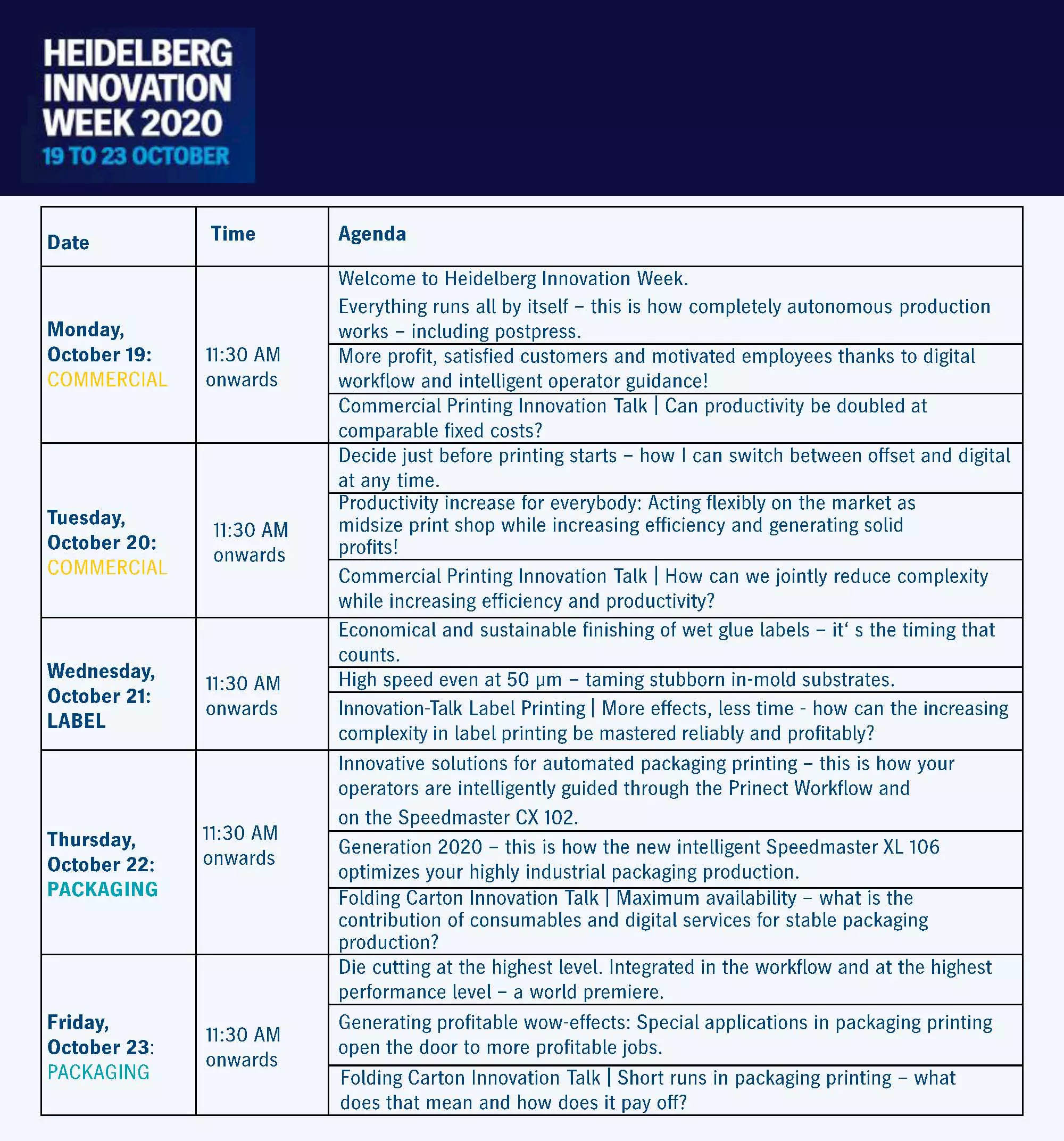

Yasmine Blair, spoke to Ludwig Allogewer, global head of marketing and sales, Heidelberg Group; Alexander Driss, head of customer success management, Heidelberg; and Juergen Grimm, head of software (Zaikio Project), Heidelberg about jointly reducing complexity while increasing efficiency and productivity

21 Oct 2020 | By Rahul Kumar

Yasmine Blair (YB) Host: What are the advance offerings from Heidelberg?

Ludwig Allogewer, global head of marketing and sales, Heidelberg Group (LA): We have one top priority – economic success of our customers. The underline criteria are – highest availability of equipment in the print shop and highest productivity achievable inside. It is sort of selfish but if the customer is successful then we will also be successful.

YB: How do you start?

LA: It starts with equipment, services, it needs consultancy, it needs a bunch of consumables and variables. It needs facilities to monitor the whole process. That’s what the game is all about. Heidelberg is working on this from decades.

YB: How?

LA: The first was atomization of all products. Second is to bring intelligence in to our machines to support the operator and focus on business view and less on the machine view. The third is to bring our machines in to the internet and the step was taken 15 years ago.

At that time nobody spoke about IOT and Industry 4.0 but we started the process. We brought all our machines in to the web which allowed us to bring more information to the customers. And that was the base for next step to offer digital services. It is called Heidelberg Eco System.

YB: How will the Heidelberg Eco system continue/help the customers in future?

LA: We will share all the knowledge we have with the machine operators. The possibilities are available with e-commerce. We are bringing everything together in seamless integration and it can be used on mobile phones as per the customers’ convenience.

We have a small HDU – Heidelberg Digital Unit established around two years ago and we have another development centre working on Heidelberg Prinect.

YB: As a printing company, how do I secure my production? How do I ensure a constant availability?

Alexander Driss, head of customer success management, Heidelberg (AD): You start by defining your complete production system. We offer our scope of services and production monitoring to our customers because maintenance is really an important point. It controls the production and reduces downtime of the machine. On the other hand, consumables are equally important because consistent quality production needs good quality and certified consumables and that’s why we suggest to our customer to use Heidelberg consumables for our machines.

YB: How can I anticipate/calculate the cost properly?

AD: We developed a solution called Print Site Contract, it is attached to the machine and you get services package, trainings/consultancies, consumables and everything is calculated on monthly basis. And so, the customer can calculate his/her cost appropriately.

YB: What kinds of contract models are available?

AD: Heidelberg Print Site Contracts are divided into two – Lifecycle Pay per month and Subscription Pay per month. Both have different modules as per customers’ requirements. We help our customers to collect and use the data in right way. The data can be integrated with consumables requirements and for that we have special solutions.

YB: In terms of consumables, how does it work when we look at it practically spoken?

AD: Once the customer gets the initial fill up needs for his production, we guide him on the requirement of types of consumables and quantity as well. We maintain inventory according to his need.

YB: What kind of trainings is offered under the contract?

AD: We provide E-training for offset and digital printing. It can be in basic, advance and professional mode.

YB: What is your approach to maintenance?

AD: We have developed a maintenance manager for maintenance which is based on cloud solutions. Customers get a detailed report to maintain individual parts of his machine. The maintenance system will be upgraded automatically. We have developed an app as well so that customer can maintain the machine directly.

YB: What is the idea behind Zaikio Industry Platform? How does it complement Heidelberg’s offering?

Juergen Grimm, head of software (Zaikio Project), Heidelberg (JG): Heidelberg did a fantastic job by automising the entire production and Zaikio is beyond that. There are many things take place except production in a printing press and we are looking in to that. It is an open platform, providing open APIs, standardise data model to allow connecting these systems with each other. It is basic task of Zaikio, being a connector. It doesn’t stop with a print shop, it is for the entire value chain.

YB: How so?

JG: In an administrative job, similar data is entered in to multiple systems. We are trying to reduce the multiple entries for same data. If all the system will be on cloud the data integration will be seamless.

Data security is the major concern and we have made arrangements for it. Zaikio is an integration platform and we don’t store data. Data security is paramount. We are connecting MIS with ERP, and printer has stored and secured all the data already.

The website is ready since July this year.

See All

See All