Harveer Sahni: Evolving and growing, digital label printing

Unlike the sudden spurt in growth of self-adhesive label industry that we witnessed in China some years back, Label printers in India have moved on steadily and cautiously. We are now considered to be either already a bigger population than China or about to surpass them in numbers, yet in times of growing demand of label and packaging, our label industry continues to exhibit resilience and achieve a steady double-digit growth.

17 Jul 2023 | By Harveer Sahni

Our printers have adopted the evolution of printing technologies with varying degrees of indulgence based on their customers' need and wish to deliver creativity and innovation. Indian label printers moved on to adopt evolution as it occurred, from flatbed label printing to semi-rotary intermittent letterpress, flexo, digital flexo and combination printing with flexo, screen, gravure, etc. all in-line. However, when it came to digital label printing, the industry treaded this path-breaking technology with extreme caution and calculated steps.

In around 2008, the first HP Indigo press was installed in China and by 2018 the number had swelled to 180 and thereafter registering almost 40 new installations, small and big, every year. While in India the first HP Indigo press was also installed at Janus International in 2008, the same time as in China, yet by 2023 the total high-end digital label presses are around 40-45 but with all small and big included this figure may have reached 60-65.

Xeikon

The author interacted with leading digital label press manufacturers to ascertain a percentage of growth of their installations, it was not possible arrive at a concrete number. This is so, because the base numbers are so small that the percentage growth rate may become misleading. Take for example; if a manufacturer has only two prior installations and just one in the current year, then it means a fifty percent growth in numbers. For sure it will not convey the actual scenario. The statement made by HP Indigo country manager Appadurai sounds more relevant.

He says, “We have seen a Triple Digit CAGR in the Linear meters of Jobs printed with customers in India . This is the most important metric of our business. We expect not only to sustain this growth but to scale it even further.” Appadurai’s statement does reflect a realistic look at the growth of digitally printed labels. However, to arrive at a realistic figure that will indicate the growth in the installed base of digital label presses, we need to dwell on the number of installations, which grew from 22 in 2017 to 60-65 in 2023. With these figures in hand, one can calculate that the CAGR rate to be 19%. Vikram Saxena of Xeikon, who mentioned the growth of installations to be 18-20% was the nearest to the figure that the author has arrived at. While at the higher end HP continues to lead in the number of installations and in the volume of investments, Monotech excels in the over all number of installations mainly due to the price advantage. Those entering the digital arena are looking for affordable equipment to start with and later upgrade. At the current rate of growth, we can expect 12 to 15 installations per year, it includes the big ones and the affordable ones.

Konica Minolta

“I believe the future of label printing is firmly in the realm of digital printing” says Shayakk Mukherjee of Konica Minolta commenting on future of digital label printing in India. The market of digital label printing, after the initial holding off until market matures, has been looking up and rapidly growing as more and more established label companies have invested in the technology that accords the ability to produce high-quality, cost-effective, and customizable labels in shorter runs. The growth of ecommerce has acted more like a catalyst for increased demand for personalized and customized labels at short notice.

Increasing focus in India towards the young population, with encouragement from Government, a whole community of startups is emerging giving a definite fillip to creation of jobs and innovating with new products that will appeal to their own generation-next. The startups need to have labels and packaging in smaller quantities in the initial stages of their journey into manufacturing. All respondents have mentioned the key advantages of digital label printing and its ability to enable shorter runs and faster turnaround times.

The vision at HP is quite expansive, they state that digital label printing besides just labels is also increasingly being used for packaging. Appadurai adds, “The trend in the label printing industry is the increasing focus on sustainability, with many companies seeking to reduce waste and environmental impact. Digital printing technology can help in this regard by reducing the need for excess inventory and minimizing material waste.” Corroborating the view Ajay Rao Rane of Domino Printech says, “Labels and Packaging converters are engaging and trying to understand the benefits they would achieve through digital printing and taking a well-informed decision about investing in the latest technology.”

Domino

Most contemporary or emerging technologies initially face a lot of hesitation by investors but once they are able to establish their fruitful deliverance, they do find people who will adopt them, though the cost of end product so manufactured does play a definitive role in decision making. Labels too have faced a similar situation. The convenience of digital printing was an awe-inspiring development, triggering wish of ownership, but the cost of labels as compared to those produced by analogue process was, and still is, a deterrent. With time the convenience of producing from computer to print without the need of extensive pre-press, plate making and long setup time, attracted many a printer’s attention. Coupled with the ability to produce customized and personalized labels with variable data many jobs became a necessity to be produced on digital label presses.

Now when rapid growth in the number of installations there is some ease of pressure on input costs but still it is much more than those printed by flexo presses. According to Jimit Mittal at Monotech, with the increase in number of digital equipment, the cost of logistics and consumables can be optimised to a certain level. Digital is no longer just for short runs but can also satisfy medium runs cost-effectively delivering value addition to any customer workflow more than the run lengths only. The HP team agrees that the gap in cost of printing on flexo and digital will narrow with an increase in numbers while the thought process at Domino is that the cost comparison between digital and flexo printing will vary depending on the specific job requirements and should be evaluated on a case-by-case basis.

Venkatesh Selveraj states, “In Durst digital solution the production cost gap is already narrowed down.” The gap in cost for both flexo and digital is substantial. Vikram Saxena at Xeikon sums it as, “This question is an irrelevant question. Both are not competitors but complimentary technologies.” Increasing print length does not mean that the job will become cost effective on digital on the contrary shorter runs are better. This is so because in flexo the prepress, plate cost make-ready and setup adds up on a small size of the job.

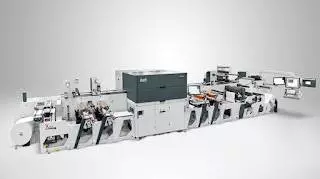

Durst-Omet Hybrid

In the last few years, as the growth started to pick up, the rhetoric was, that digital printing is good only for short runs. Well, that seems to be changing now. Increasing widths and speeds are driving in change, on as to how labels are being made, using digital label presses. They improve production efficiency, allowing label printing companies to produce a wide range of products with reduced setup costs and time impacting overall cost. In fact, the product portfolio of these presses has expanded to include flexible packaging and folding cartons.

Equipment like Durst has already achieved a speed of 100 meters with a wider width enabling production of IML, Lamitubes, Shrink sleeves, Flexible Packaging and folding cartons. Ajay at Domino made an interesting comment. “There is continuous evolution in the Digital printing segment, resulting in faster and wider machines which offer a better TCO(Total cost of ownership) to the labels and packaging converters, helping converters to produce more jobs in lesser time. HP for that matter is a trailblazer in going wider at higher speeds.

Their 25K press installations already deliver 740mm width and are attracting investment from producers of standup pouches, flexible packaging and shrink Sleeves. Their latest offering HP Indigo V12 press that was showcased at the Labelexpo Americas last September, which prints at 120 meters per minute, will surely change the way medium-long run label jobs are printed. They call it INDIGO FIRST strategy. A label converter having both digital & Flexo presses will obviously put short runs on digital and medium or long run on Flexo, but the V12 will change the sequence. 80% of jobs will become suitable to be printed on HP Indigo V12. As per Jimit Mittal at Monotech, speeds of 50-70meters per minute in widths of up to 330mm is enough for labels, however the equation changes when you plan to produce packaging as well.

Monotech

Most of the respondents in response to the author’s questions have expressed that digital label printing is now not limited to short runs. There are companies like Trigon Digital, Leap Digiprints, Digistick, etc. who are only committed to digital printing and have plans to stay invested in the same technology and expand in it. When asked if in future digital will replace analogue or flexo or Hybrid the general opinion was that there does not appear to be such a possibility in the near future, but in fact the two will be complimentary technologies to each other. In the western countries, more digital presses have started being sold than conventional ones.

But this may be because of a smaller base of installed digital label presses in comparison to conventional ones and the pressing need of printers to expand their capabilities and cater to needs of customized, personalized or variable printed labels. Most successful label companies will have these two technologies in their companies together.

The growth of digital printing gets enhanced when the equipment manufacturers promote their products. The standard procedure followed is to display their products at industry exhibitions. Labelexpo and other printing shows have been seeing an increased presence of digital printing equipment manufacturers in recent times. Being a technology that is still evolving, there is a lot to be learnt by the printing fraternity. The first knowledge about digital printing comes when new prospects visit the exhibitors stands at the printing shows, but the more detailed information comes when sales and technical professionals make presentations to printers at their own offices followed by showcasing existing installed running presses at other printing companies.

Unlike other printing technologies like flexo, offset, screen and gravure, there are many variants in technology as to how digital printing is done. The diverse types of technologies available leave the printers in confusion as to what is the most appropriate technology in which they should invest. Available technologies offered by various manufacturers of digital equipment are as follows;

- Dry toner based.

- Liquid toner based.

- UV Inkjet

- Water-based inkjet

Exhibitions, direct mail and personal reach-out to educate prospective customers about their equipment, remains the most preferred marketing process for digital label press manufacturer. However, the modus operandi by Domino and HP is stated to be a little different.

Ajay Rao Rane of Domino states, “We also engage with the brand owners to evangelize the benefits of Digital printing to them.” HP goes a step ahead and Appadurai at HP sums it up, “We invest a lot into educating brand owners about the benefits of digital printing, we always look for creating more opportunities for our PSPs, apart from working with large brands in creating campaigns like share a Coke, Kit-Kat valentine pack, Dettol covid warrior pack, we also work extensively with many association of food & beverages, pharma, personal care to educate the brands associated with them on the benefits of digital printing, which saves them lot of cost, (better cashflow), faster time to market, while also helping them to use more sustainable printed packages.

The future of digital printing is growth oriented, and it will keep evolving as all electronic, IT based, or AI based products keep changing constantly. But then as it is said, “Change is the only constant!” As a matter of fact, the changes come so fast that the winners will be those who adapt to this change quickly to offer innovative products ahead of others.

Harveer Sahni is the chairman at Weldon Celloplast. The author is indebted to respondents who provided some important inputs for this article. They include Ajay Rao Rane of Domino, Shayyakk Mukherjee of Konica Minolta, Vikram Saxena of Xeikon, Jimit Mittal of Monotech, Venkatesh Selveraj representing Durst and Appadurai of HP.

See All

See All