Uflex's new CI flexo printing press is targeted at short-run print jobs on PE and stretchable films. Rahul Kumar examines how this machine can be a viable alternative to gravure printing

The engineering business of Noida-headquartered Uflex showcased its first CI flexo printing press to the public on 8 March 2018. The gearless flexographic printing press has been developed in collaboration with Italy-based Comiflex. The two companies signed a technology transfer agreement at Drupa 2016.

Marketed under the brand name Uflexo, the machine comes in two variants — Elisa and Valle. The major difference between the two is its operating speed of 400m/min and 300 m/min, respectively. The first machine to be launched was Uflexo Elisa 1409.

Flexographic printing uses a flexible relief plate to print onto a substrate, which may be wood-pulp-based, synthetic, or laminated. Such substrates may also include films, such as polyester, OPP, nylon, and polyethylene; papers; paperboard; non-woven textiles; and coated or un-coated liner board. The raised areas on the plate have ink applied to them by an anilox roller and then transferred it onto the substrate.

The technology

In the case of central impression (CI) printing press, the decks are arranged around a single, large diameter impression cylinder.

According to Ajay Tandon, president and CEO, engineering and new product development at Uflex, Uflexo Elisa 1409 is ideal for flexible packaging on thin substrates like PE, BOPP, BOPET, CPP and paper. “Unlike a rotogravure printing press, where the printing stations are arranged in line one after the other, in a CI flexo machine, the printing stations are arranged around the periphery of a single, large diameter impression cylinder,” he says.

Tandon says the machine is for convertors across the globe. “We are manufacturing the machines at our engineering plant in Noida under a technology transfer agreement with the Italian firm Comiflex. Gianfranco Nespoli, head of Comiflex, who is a technocrat, played an instrumental role in helping us manufacture these state-of-the-art printing presses in India. We can market these machines anywhere across the globe,” he adds.

The selling point of the Uflexo is that it can print on thinner substrates, which, according to Tandon, is not possible in gravure printing. “We can print on PE as thin as 25-30 microns. The changeover time of this machine is very short in comparison to other printing processes, making it further suitable for shorter runs,” Tandon says.

Also, the machine is low on ink-consumption, thereby making the entire proposition further cost-effective. Again in places like Europe and US, cost of procuring plates for flexographic printing is significantly less than that of gravure cylinders.

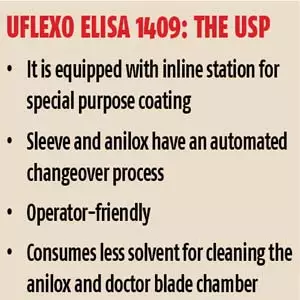

The machine is equipped with the inline station for special purpose coating, and sleeve and anilox have an automated changeover process. It is very operator friendly and consumes very little solvent for cleaning the anilox and doctor blade chamber.

Additionally, the Uflexo Elisa 1409 has an inline station for special purpose coating.

“We manufacture bespoke converting and packaging machines. The engineering business of Uflex proposes a series of additional features over and above the base model to the customers to select from,” Tandon says.

In short, Uflexo Elisa 1409 is very efficient. The changeover times are short. Registration matching time is less without much wastage. “These are some of the factors that enhance productivity,” he adds.

The market

The Uflexo Elisa 1409 is the first gearless CI flexo machine that Uflex has manufactured in India. The first machine is being installed within the group at its converting business’ precinct.

“We already have three orders at hand and expect to manufacture around four to five machines over the next 12-15 months. These are very sophisticated and customised machines that are made to order,” Tandon says.

Talking about sophistication, what is it that customers look for in a CI flexo press? Tandon answers: “A customer usually selects CI flexo press if the substrate is polyethylene or stretchable film. For shorter runs, CI flexo machines are certainly desirable. The cost of procuring plates for CI flexo is less than the cost of procuring gravure cylinders. Therefore, when the operational costs have to be optimised, a customer would prefer CI flexo printing machine.”

While CI flexo is seen as an alternative to rotogravure printing, Tandon says gravure is more viable for longer runs. He adds, for narrow-web and printing of labels, digital technology is also becoming increasingly popular for some high-end applications.

Again, compared to a gravure printing machine, CI flexo printing machine requires almost 50% less space for the same quantum of output. This works as a big advantage in favour of CI flexo.

Software/consumables

The Uflexo Elisa 1409 is equipped with a complete drive system of Bosch Rexroth and is programmed suitably for efficient running making it operator-friendly with many safety built-in features.

The machine, by and large, use alcohol-based inks. Water-based inks can also be used with a change in the inking and drying systems as per customers’ requirements. “Our chemicals business manufactures various types of inks, adhesives, coatings and polyols required by flexible packaging convertors,” Tandon says.

Support and best practices

“We have in place trained and agile installation; commissioning and support teams. Our customer support, in particular, can offer real-time assistance through remote monitoring with the help of ethernet or optical fibre. For capital equipment that we manufacture, customer support is an extremely critical component of our product and service offering,” Tandon says.

He adds that the central impression drum and printing deck parts are very precise in nature. Therefore, the machine preferably should be operated in a dust-free environment. Temperature and humidity should also be properly controlled for optimum results.

Tandon says the use of flexo printing technology is on a rise as single polymer flexible packaging is becoming popular by the days from the point of view of recyclability. With increasing varieties of SKUs and products, the job runs are becoming shorter, again building up a case for flexo printing machines.

Technical specifications

Number of colours: Eight

Printing possibilities: 8 + 0

Printing width: 1300mm

Web width: 1350mm

Printing repeat: 340-800

Printing speed: Up to 400m/min depending on type and quality of materials to be printed, inks, cylinder repeat, plates, ink coverage with colour overlay

Plate thickness: 1.14mm (0.0045-inches) plus adhesive 0,5mm (0,0020-inches)(any plate thickness depending to sleeve/repeat)

Anilox sleeves: Diameter 172mm ceramic coated sleeves

Ink: Solvent and water-based

Material: HD-LDPE / 14-100um / PP, 10-50um / PET 10-50um /, Paper 40-80gsm

See All

See All