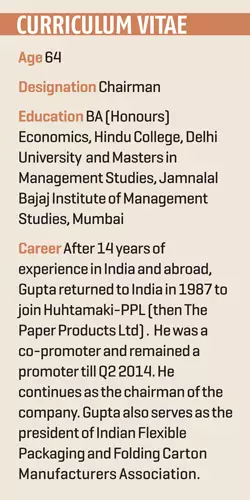

Innovation, investments, ideas, implementation: An interview with Suresh Gupta

Suresh Gupta, chairman of Huhtamaki-PPL (HPPL), leads one of the largest packaging companies in India. It is a very different company from the one he had joined in 1988 as a co-promoter. Today, the packaging major has established a pan-India foothold with 15 ultra-modern factories that reflect Gupta’s keen eye for innovation, people strength, and prudent investments

29 Jun 2017 | By Rushikesh Aravkar

In hindsight, do you feel you should have integrated backward to make Huhtamaki-PPL even stronger and a bigger entity?

We are sufficiently backward integrated in terms of our own blown and cast film lines, pre-press and cylinder engraving facilities and in-house expertise on inks and lacquers. Beyond a point, while backward integration may have certain advantages, we prefer to focus more on our core competencies and in customer-facing investments. It is evident from our past endeavours that we believe in quality and self-driven processes, backward integration often leads to lack of supplier competition resulting in lower efficiency at potentially higher costs. In due course, it is likely that the flexibility will get reduced owing to previous investments upstream as well as downstream.

What is the growth you envisage for your company in the next couple of years? What factors and investments will drive this growth?

Generally, in emerging economies, FMCG growth is twice the real GDP growth. Growth in flexibles is a bit faster than FMCG growth rates due to the ongoing shift from rigid packaging to flexible packaging. In view of the this, we have aggressive growth plans in the pipeline, backed by investment support. This will include setting up new manufacturing facilities, introducing new technologies and upgrading existing ones, along with potential new acquisitions and capacity enhancement in existing plants.

Our large investments in our new flexibles project in North East India makes us the only packaging player to have a strong manufacturing presence in all four Indian geographies. Our pressure sensitive label business, Webtech Division, commercialised a new plant in Sikkim in March 2017. Huhtamaki recently took over Val Pack Solutions – a supplier of a comprehensive range of paper cups – to enter the foodservice packaging market in India. The integration of Positive Packaging with HPPL has gone through smoothly, with the legal merger also being completed earlier this year. We will continue to introduce and develop new technologies to grow faster than the market.

Tell us about the new plants in Assam and Sikkim…

To service our customers better in North East India, a new flexible packaging manufacturing unit went on stream in Assam and a PS label manufacturing unit in Sikkim. Both plants are fully operational and have received an encouraging response from our customers. The Sikkim unit will cater largely to our existing customers who have moved into the area and we expect the unit to go in for an expansion soon.

Huhtamaki-PPL has invested significantly in building state-of-the-art manufacturing locations. There is a tremendous amount of technology momentum. How do you juggle between upgradation of technology and return on investment?

The year-to-year viability of a company depends on its ability to innovate, both in products offered as well as technology spread. Given today’s market expectations, global competitive pressures, and the extent and pace of structural change, this is truer than ever. We at HPPL have always believed that the strongest innovation track records can articulate a clear innovation ambition; we have tried to strike the right balance of core, adjacent, and transformational initiatives across the enterprise; and have put in place the tools and capabilities to manage these various initiatives as parts of an integrated whole. We at HPPL always strive for achieving “total innovation”. There are two things we have adhered to throughout: Be clear about our innovation ambition and strike and maintain the right balance. Transformational initiatives are the engines of high growth and these transformational changes can come swiftly only with a fierce technology momentum. We are proud to say that our technology momentum is supporting our ROI in a positive way.

One of the strengths of Huhtamaki-PPL is its people. What kind of HR policy does Huhtamaki-PPL possess to motivate your task force?

Yes, of course, our people are our strength as we have always believed in the saying: happy employees create happy customers. It is appropriate to repeat our people philosophy here. “It is people who face and overcome challenges. Their approach, knowledge, commitment and actions are what finally deliver. An open, hands-on culture, which involves and empowers, which believes in sharing and training, and inculcates pride in knowledge – all this is our philosophy and we need to continuously ensure that it is also our practice.”

At HPPL, people are respected and performance is nurtured. A flexible work environment, high level of empowerment and accountability where each employee owns his area of domain, leadership development through mentoring and coaching, skills and competency development initiatives, multicultural exposure through diversity and inclusivity are our key initiatives throughout the year. Other than these, there are various benefit programs which we run for our employees including his / her family, insurance, health and wellness, financial and retirement, family and parenting, vacation and time off, perks and discounts. This is our gesture to ensure that our people are comfortable in one big HPPL family.

We are committed to high ethical standards and practices and this gives a strong confidence to our people when they operate in the market.

Team Huhtamaki-PPL at Interpack 2017

How do you see the shift in the wider packaging landscape in last 10 years in India in terms of the market’s evolving needs and the impact of new technologies?

The rapid shift to packaged processed goods from rudimentary or non-packaged goods started 30 years ago and was majorly completed 10 years ago. The main acceleration in last 10 years is the movement to world class standards, something we have always pioneered, and the movement of fresh produce fruits, vegetables, and meat into packaging.

Globally, there has been a shift in consumer’s buying pattern. Instead of bulk packaging, customers are now opting for smaller packs and ready-to-eat options. There has also been a reunion of package structures and branding, with a focus on clean and comprehensive label messaging combined with a consumer perception that correlates quality of a product with the quality of packaging and the ease of usage associated with it. Following global footsteps, Indian consumers have started looking for portable packs options, single serves, retorted food options, etc.

Considerable development in the pouching vertical has happened as a result. With this paradigm shift, consumers worldwide are getting increasingly conscious of environmental issues related to packaging. There have been concerted efforts to bring green packaging materials into focus while maintaining focus on the role of resealable or reclosable packaging in reducing the wastage of the product inside.

People’s changing life patterns, buying power and disposable income is playing a pivotal role on this topic. This is indeed a good sign for the future of the packaging industry in India.

At the same time, the market and government both are expecting innovative changes. This will set a new benchmark for the Indian packaging industry in the near future. There is clearly more and more to come “for” and “from” this beautiful industry.

Kinder Joy Maxi: thick thermoformable laminate

Innovations in flexible packaging have been limited to down-gauging and lowering packaging cost. Why aren’t flexible packaging convertors trying to add value through real innovations rather than succumb to pricing pressures?

This cannot be generally agreed; though it is a fact that big organised buyers heavily influence packaging material suppliers to cut corners to reduce cost. However, we have worked with our customers in bringing some really innovative concepts in the market, one example being Paper Boat which has given a totally new dimension to traditional Indian beverages. Our rate of new product development is high and we are the leading player in the start-up arena or new product launches.

Although we understand Huhtamaki-PPL is focussed on flexible packaging (the reverse printed laminate structure), what is the update on the barrier film market?

We are definitely into barrier films like multi-layer nylon and EVOH (high-barrier) based films for oxygen barrier. Our multi-layer nylon film is catering to large requirements in the edible oil, food, spices and agro-chemicals segments. We also believe that the market of the barrier film in India is still at a very nascent stage and is expected to grow in years to come for which we are already prepared.

How are you looking at bringing about innovation in packaging? What kind of innovations does Huhtamaki-PPL have to its credit in the last couple of years?

Innovation is the only way to win. This is our anthem at HPPL India. HPPL has a rich history of global recognition for achievements in numerous awards that we have won across national and international forums like IndiaStar, AsiaStar, DuPont, WorldStar, to name a few. These awards represent the highest level of excellence in the field of packaging applications.

Every year we have nominations across different innovation awards. On specific products, we have worked with Hector Beverages on Paper Boat, our Moscovsky profile pouch is a unique combination of aesthetics and material specification to take care of the product requirement and is popular in the Russian market. Our special pouches for dosa and idli batter are very user-friendly and extremely popular in that segment. Our pack for Knorr (Thai Vegetable Soup) has an excellent combination of matt and gloss effects, imparting a premium visual to the pack. We won two WorldStar Awards in 2017 for Tzinga profile pouches and Horlicks Gold pressure sensitive label.

Growth and new product development are driven by our innovation programme called NASP (New Applications, Structures, Products and Processes). NASP is institutionalised within HPPL, with various team members at various levels taking it up as a personal mission, making it an important component of the culture of HPPL. Our NASP program helps our customers in many ways, of which two are particularly noteworthy. Our new products, which are based on upgraded technology processes, serve our customers’ need for adding value to their products and offer additional benefits to their consumers. We also continuously work on solutions which offer cost advantages without compromising performance. Hence, NASP creates business growth, but equally important, it also protects or even improves existing business share from a customer by creating improved packaging solutions, or improving cost competitiveness. Our products which have emerged through the NASP process are recognised by distinguished industry bodies, and we were recently awarded two WorldStars, five AsiaStars, three IFCA Stars and an ET Polymers Award.

WorldStar 2017 award winners: Tzinga profile pouch and Horlicks Gold PS label

What is your take on the impending legislation on banning multi-layer laminates, its feasibility and impact on industry and technology?

The flexible multi-layer laminates are designed through optimal usage of different materials to get cost-effective packaging material considering essential needs such as barrier, strength and visual appeal. A potential ban on multi-layer laminates will cause a considerable increase in packing cost and sub optimal solutions. Globally, multi-layer plastics are the “most preferred” and favoured packaging materials compared to others because of low weight, the cost of transportation and various other benefits. The Central Pollution Control Board has included “plastic” under “Green Category” meaning “least polluting” as it is recyclable and that alternative packing materials like paper and aluminum foil are actually more environmentally regressive.

While there is a lot of ambiguity in terms of expectations looking at the current alternatives, we are working on designs to make packaging materials recyclable through the use of materials of the same polymer family.

With mono-layer and toluene-free emphasis, will the market move from Gravure to CI-flexo?

CI-flexo has been an underrated technology in India but it is fast catching up now with gravure. With the emergence of thin mono-layer films, yes CI-flexo will have a definite advantage. However, CI-flexo has still a long way to go in terms of developing the right ink solutions and quality plate suppliers apart from having consistent film suppliers.

HPPL’s flexible laminate plant – II in Silvassa

What are your views about water-based inks in gravure?

Water-based inks are always preferred over solvent-based systems. However, water-based systems require a significant change in printing machines, particularly in the dryer systems. It is expected that the water-based inks will slowly replace solvent-based inks in future, with water-based inks getting evolved for wider and improved performance. There are many advantages such as low VOC (volatile organic compounds), low incineration costs, reduction in health hazards, reduction in overall operation costs, increased life of printing cylinders, greater ink mileage, reduction in environmental costs, improvement in plant hygiene, reduction in potential of toxic material discharge, non- flammable, less wear and tear of gravure doctor blades and many more.

In your entire career in the packaging industry, which period was the most exciting time for the Indian packaging industry? With respect to that period, how will you describe the current situation of the Indian packaging industry?

All the years have been exciting as year to year the vast chasm between Indian and world class practices was being bridged. The most exciting time is yet to come as we complete the bridge and all our 1.3 billion people experience the benefit of high-quality packaging.

When do you expect an overall revival in the economy and what would drive growth?

While I am a student of economics, I am not in a position to predict a specific date of revival of the Indian economy. I definitely think that GST implementation will help the economy grow faster than the current rate.

As captain of the industry, one suggestion you would like to share with the Finance Minister for the next Union Budget?

Industry benefits from a robust society. For this, we need a real focus on education and health. These areas are given step motherly treatment and hence we are a poor country. This needs to change.

See All

See All