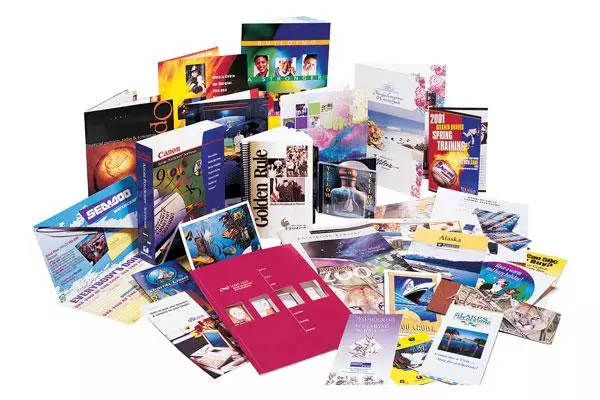

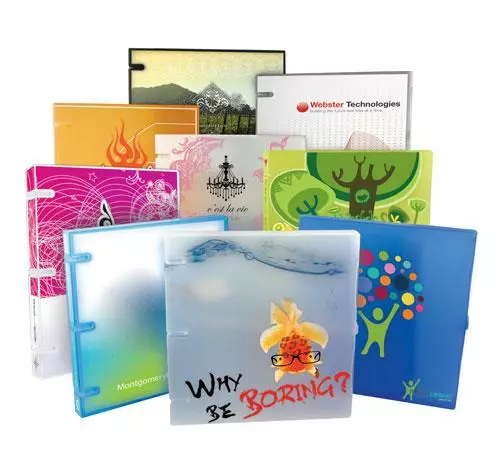

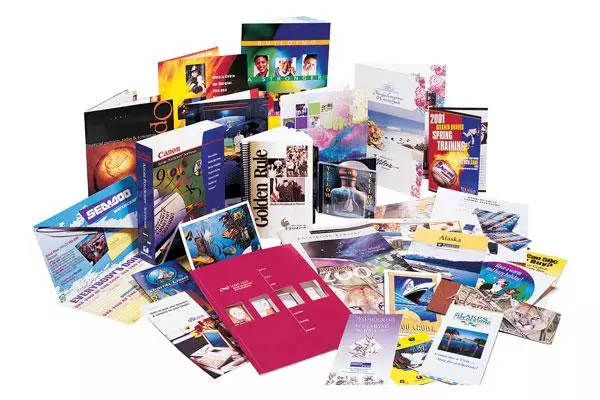

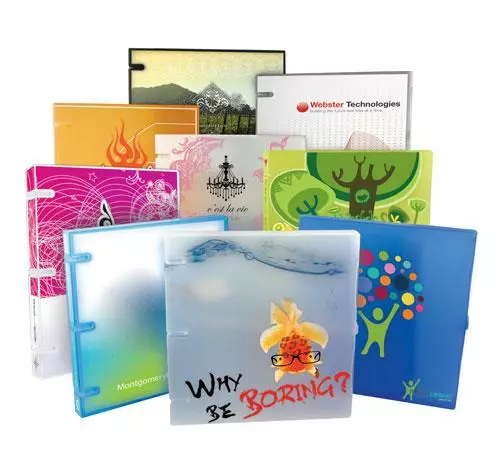

Located centrally at the Industrial Town Rajajinagar, PentaPlus has a brand new four-color Komori Lithrone 428 which can print up to 15,000 copies per hour and a single colour. With in-house pre-press, printing and post-press facilities, the firm produces brochures, leaflets, carton boxes, booklet and stationery products. An important factor of its success, says Krishnappa is "continuous upgradation of technology to improve our processes and serve better with best quality and best price for our customers’ changing needs."

Shripad Bhatt: What’s the reason behind your success?

Shripad Bhatt: What’s the reason behind your success?

Krishnappa U C: Hard work and patience! Even today I do not sit idle for a single minute. Even those days when I was single handedly running my screen printing business, I used to do DTP work, expose screen, print, and deliver jobs to customers, bring materials, etc. Often for seven days in a stretch, I did not have proper sleep as I had to work at night to finish jobs and deliver in the morning.

SB: You are a self-made entrepreneur?

KUC: I can proudly say it all began with screen printing. It’s easy to start a screen printing business as it involves bear minimum investment including a small place I had just 80 sq/ft. Getting into direct offset business was difficult those days. Investment was not only the issue; when you establish name in the market as quality printer, only then can you get regular business.

SB: Any short cut for success?

SB: Any short cut for success?

KUC: You need lot of patience as screen printing is a lengthy process. For three-four months I was single- handedly running my business, and once I made some money I could afford to employ a helper. My first bill was Rs 40 in 1991 for one lot of visiting card printing.

SB: Why did you embrace automation?

KUC: Having worked in a manual screen printing, I personally know how difficult and tedious is manual screen printing? And my growth strategy has always been directed towards adopting new technologies, even at a price, for the ultimate benefit of our customers. So, I was equally inclined to adopt automation in screen printing as we had manual tables until 2014. Automation was required to explore various UV special effects. In manual screen printing we used to face registration problem as well.

SB: Your view about screen printing?

KUC: At the initial stage of my business, screen printing was needed for sustenance of life. But now advanced screen printing is a part and parcel to supplement our offset printing business.

SB: What’s your strategy behind having a screen/offset printing combination?

KUC: In offset commercial and packaging printing, screen printing can become a decoration or make up tool to beautify the multicolour jobs printed on the world’s best offset press. It’s like giving one last touch to a bridegroom who are ready to enter the marriage.

SB: Which aspects of screen printing do you admire?

SB: Which aspects of screen printing do you admire?

KUC: Today, spot UV (matt and gloss) is a very common practice in print finishing. On the other hand, the NewAge UV special effects (such as emboss effects, wrinkle, abrasive, reflective UV, crystal UV, gold and silver glitter, etc) are like giving one that last finishing touch to bridegrooms who are ready to tie the knot. Without that attractive finishing touch of screen printing – what in today's terminology called as value addition or print decoration – the offset printed job looks incomplete. I sincerely feel something is missing. Few decades ago, without print finishing /spot UV, customers were happy with only offset printing.

SB: What is the role of screen print in print finishing?

KUC: Moreover, we can bypass the embossing work (part of print finishing) as we can achieve the same result in advanced screen printing by using UV emboss effects. This cuts down one extra process /cost involved in print finishing and thus saves time as well. As an offset printer, there is logistics comfort when you have an in-house screen printing facility instead of outsourcing. It speeds up work and it is convenient when you have regular print finishing on offset printed job. We can keep a tab on what’s happening.

SB: Your experience with Grafica?

KUC: I have been reading about Grafica’s machines in print magazines, and that prompted me to buy the machine. Post installation of their machine, Grafica’s personnel provided training on UV special effects for 3 to 4 days.

Meet Krishnappa U C, the director of PentaPlus Printers, Bengaluru, says, "screen printing was the foundation-stone of my success in the printing business.”

Meet Krishnappa U C, the director of PentaPlus Printers, Bengaluru, says, "screen printing was the foundation-stone of my success in the printing business.” Shripad Bhatt: What’s the reason behind your success?

Shripad Bhatt: What’s the reason behind your success? SB: Any short cut for success?

SB: Any short cut for success? SB: Which aspects of screen printing do you admire?

SB: Which aspects of screen printing do you admire?

See All

See All