Interest for Interpack 2017 rises to fever pitch

If Drupa is the world’s biggest show for the printing industry, Interpack is definitely its equivalent for packaging and processing. And going by the latest reports, Interpack 2017, to be held at Dusseldorf, Germany from 4 to 10 May, is going to be the biggest ever.

31 Mar 2017 | By PrintWeek India

According to Masse Dusseldorf, the organiser of the event, Interpack 2017 has recorded the highest demand among exhibitors in its history of over 55 years. By the official closing date of the international event for packaging and related processing industries, exhibitors had booked about 20% more space than was available at the exhibition centre with its 262,400 sq/mt in 19 halls. Around 2,700 exhibitors can therefore be expected again from about 60 different countries.

Industry 4.0

Where size and internationalism are concerned, Interpack is a unique platform for businesses offering products and solutions in packaging technology and related processes, as well as packaging media and materials for the various segments — food, beverages, confectionery and baked goods, pharmaceuticals, cosmetics, non-food consumer goods and industrial goods. The products and services presented here will be supplemented by several innovative specialist areas.

Working together with the German Engineering Federation (VDMA), Interpack 2017 will put the focus on Industry 4.0, in particular. The special show will take the form of a Technology Lounge at the VDMA stand, featuring examples of solutions in packaging machinery and process engineering and opening up new opportunities for applications in security, traceability, copying and counterfeit protection as well as in customised packaging.

Innovation Park

As before, Save Food will play a role at Interpack 2017. A special show called Innovation Park (innovationparc) will be held, with packaging ideas and solutions designed to reduce food waste. This includes the winners of the international competitions for the Save Food Packaging Awards, held by the World Packaging Organisation (WPO). The prizes were awarded prior to Interpack, and the winners are now set to compete with one other for the WorldStar Awards at the trade fair. The innovationparc will include a presentation forum which can be used by companies to showcase their ideas and solutions.

Components

As before, another trade fair, entitled Components Special Trade Fair by Interpack, will be running in parallel. It will feature products from supplier industries of the packaging sector. Following its première in 2014, the general idea of this trade fair has been substantially revised for 2017. Visitors will now find it at a central location within the exhibition centre, in Hall 18, a temporary lightweight hall, approximately 5,000 sq/mt in size. It is situated between Halls 10 and 16, complementing Interpack for its entire duration.

Hundreds of companies from the supplier industries will have their stands, offering products in drive, control and censor technology, industrial image processing, material handling technology and other (machine) components.

Resources

For visitors, www.interpack.com contains useful resources to prepare and plan each day at the trade fair. These resources include an exhibitors’ database with the option of compiling a personalised hall plan as well as a ‘matchmaking’ function to contact exhibitors and to receive news of companies represented at the trade fair.

In addition, a visitors’ app is available for iPhone and Android users. Its functions include the exhibitors’ and event database, updated on a daily basis, graphically optimised hall plans and exhibitors’ details, including contact details and product information, an appointment form and the option of adding customised notes to exhibitors’ entries.

Must-see products at Interpack 2017

With exhibitors still putting their plants for Interpack 2017, we bring you an early sneak peek of some key product showcases to watch out. Watch this space for an updated list soon

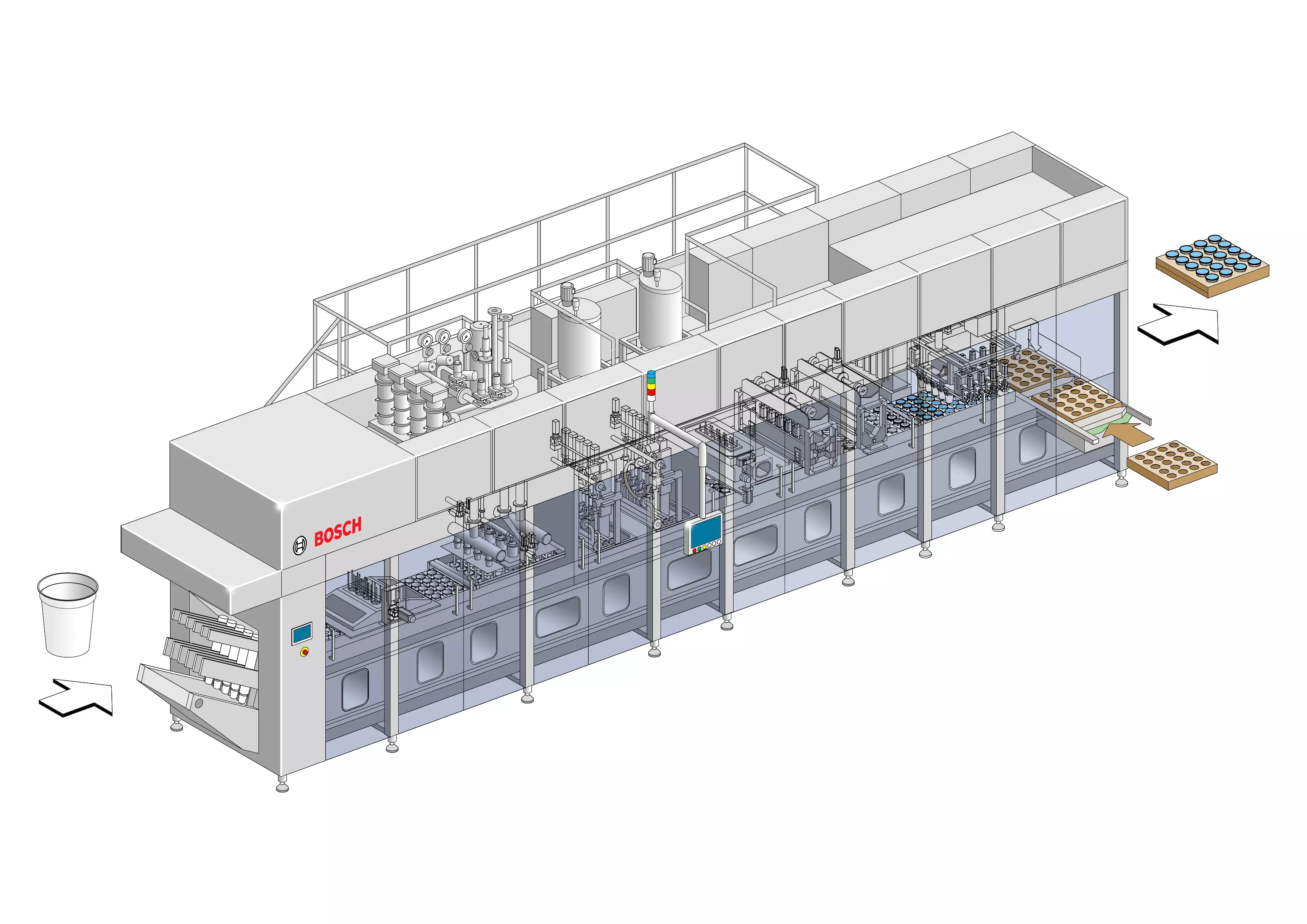

Comprehensive portfolio for solid pharmaceuticals

Bosch Group

Hall 6/ A30-C58

At Interpack 2017, Bosch Packaging Technology will present its latest solutions for solid pharmaceuticals. According to Christian Treitel, head of pharma business development at Bosch Packaging Technology, the focus is on technologies and services that allow customers to develop, manufacture and package their products, from powders to tablets and capsules. “One highlight is our new Xelum platform, which enables us to take the step from batch production to continuous manufacturing,” he added.

With the new Xelum platform, Bosch promises to offer an innovative solution for the continuous production of solid pharmaceuticals. For the first time, one system combines all of steps — dosing, mixing, granulating and pressing — and that too fully automatically and without any interruptions, paving the way for more efficient tablet manufacturing.

Based in Waiblingen near Stuttgart, Germany, and employing 6,200 associates, the Bosch Packaging Technology division is one of the leading suppliers of process and packaging technology.

As an example of its broad portfolio from small-batch development to production scale-up, Bosch will showcase the Solidlab 2 fluid-bed and drum-coater module. “We don’t just provide customers with individual machines. Our formulation and processing experts also support them with extensive pharmaceutical knowhow and a wide range of training seminars to help them implement their ideas,” Treitel said. In addition, the latest automation solutions facilitate formulation, quality control and data handling. The new phase-testing device, for instance, makes it possible to automatically determine the stability of liquid, creamy or pasty formulations.

At the show, Bosch will also launch its first ‘made in Germany’ TPR 500 tablet press. “By transferring production from England to Waiblingen, we have further expanded our Waiblingen facilities’ portfolio,” said Treitel. “As a result, we can directly apply the latest technological innovations from our proven capsule fillers to the tablet presses, and optimally capitalise on synergy effects.” Equipped with a 56-station rotor, the TPR 500 has an output rate of over 400,000 tablets per hour.

When it comes to secondary packaging, Bosch’s portfolio includes a broad range of cartoning machines. One example, to be displayed at Interpack, is the horizontal cartoning machine CUT 1405, which offers impressive flexibility in the choice of feeding systems, formats and closure variants. A CPS module with checkweigher and tamper evident labelling function serialises the folded cartons. When combined with industry 4.0 technologies, such as Bosch’s CPI software, customers receive a complete serialisation solution that not only supports all current guidelines, but also provides multi-level connection with the company IT.

The focus is on solutions for preventive maintenance as well as services to eliminate unwanted machine conditions as quickly as possible. To this end, Bosch provides a worldwide service network with qualified field service technicians who offer regional support.

Integrated packaging solutions

Multivac

Hall 5/ E23; 17/ A51

At Interpack 2017, Multivac will present itself as an experienced manufacturer of automation solutions. The solution portfolio covers all types of automation tasks and levels of integration. With a holistic understanding of customers’ products and requirements, the processes for infeed, marking, quality inspection as well as cartooning and palletisation are also integrated in fully- automated solutions, in addition to packaging. This is why Multivac will display a complete line for packaging sliced goods at Interpack.

The R 235 thermoforming packaging machine is specially designed for producing flat packs of sliced products. A quick-change system for the forming and sealing dies makes it easy to convert the machine to other pack formats. Various labelling and marking systems can also be integrated easily. The R 235 can also be equipped with a jumbo film unwind for lower webs to reduce machine downtime.

For loading of packs with sliced goods, two different loading systems will be showcased — the Multivac Horizontal Loader as well as Multivac Pick-and-Place system. Both systems are designed to insert sliced products into packs safely and hygienically with a high cycle output. The products are labelled by the L 330 conveyor belt labeller. The line is equipped with the H 130 handling module for cartoning.

The Multivac Group has approximately 5,100 employees worldwide, with some 1,900 based at its headquarters in Wolfertschwenden, Germany. With almost 80 subsidiaries, the group is represented on all continents. More than 1,000 sales advisors and service technicians throughout the world use their knowhow and experience to the benefit of customers.

InnoDry Block

KHS Group

Hall 13/ A31

At interpack, the KHS Group will have compact and flexible systems on display. With its integrated buffer system, the newly developed KHS InnoDry Block permits accumulation-free, gentle pack conveying without the side guides otherwise required. This does away with the need for adjustment during format changeovers. The systems supplier from Dortmund will also be highlighting its new features in secondary packaging. To this end, at the trade show KHS Service will be presenting special conversions and its new service concept for packaging machines.

“Where two or more single machines can be compiled to form a compact block system, this gives operators numerous advantages,” said Karl-Heinz Klumpe, packaging product manager for KHS.

The KHS InnoDry Block combines a packaging machine with a palletiser and has a handle dispenser integrated into the packer. This setup is made possible by especially flexible buffer areas and the use of a highly dynamic handling system for layer formation which is being used in the blocked machine concept for the first time. Shorter conveying segments and, as a result, a considerable reduction in maintenance effort speak for the compact block. Format changeover times are also shorter as side guides are no longer needed on the conveying segment.

Meanwhile, Dusseldorf-based NMP Systems will exhibit trendsetting packaging systems at the KHS booth in the form of direct print powered by KHS and Nature MultiPack, for which NMP is responsible.

KHS will also display a high-performance system in the context of its partnership with packaging manufacturer Gerhard Schubert. Together, the two companies have developed a compact, multifunctional packaging block, which is distinguished by its great flexibility regarding cardboard packaging. It combines a Schubert erecting and closing module with a KHS packer and can even be expanded using the KHS Innopack system to produce film-wrapped and shrink-film packs. Operators who make the maximum demands of a modern packaging system therefore save space and at the same time enjoy greater flexibility.

Marking and print solutions

KBA

Hall 12/ C36

Four companies from the Koenig & Bauer Group, which makes almost 70% of its sales of new presses with printing, marking, finishing and further processing technologies, will present a selection from their wide range of solutions at Interpack 2017 in a joint stand.

KBA-Metronic: Digital communication between man, machine and product is a central issue for the marking specialists at KBA-Metronic. Metronic marking systems with the code-M software module allow, among other things, the centralised administration of print jobs, the monitoring of entire marking lines and the integration of camera control systems. With the code-M data module, data from databases can be inserted into printed texts.

Printing systems and fields are detected automatically, and the form of the imprints is user-definable. With the code-M data and code-M editor modules, users can create sophisticated text layouts themselves. For the first time, KBA-Metronic will also present the betaJETxenio. The tried and tested DOD inkjet system is highly versatile. The product portfolio with thermal, inkjet, laser and combined printer units covers current market requirements.

KBA-Sheetfed: In virtual presentations, KBA-Sheetfed will show the digital sheetfed press KBA VariJET 106, powered by Xerox for folding box printing. The KBA VariJET combines conventional printing and finishing technologies with digital inkjet printing. This hybrid press supports regional and campaign-specific versions of packages, value added and infotainment packages as well as database-aided sales campaigns. KBA will also be providing information about its flatbed and rotary stamping units.

KBA-Flexotecnica: For its new-generation CI flexo presses for flexible packaging materials, KBA-Flexotecnica focuses on migration-free printing with water-based inks, especially for food packaging. The new laminating machine Evolam, which allows the use of solvent-free adhesives, will also be presented.

KBA-Kammann: Digital inkjet printing is also gaining ground in the direct decoration of premium hollow bodies made of glass, plastic and metal. KBA-Kammann, the international market leader in screen, hot embossing and digital printing systems for decorating hollow glass bodies, will be showing this at the Interpack. The flexible Kammann systems allow the optimum configuration of applications to meet the diverse requirements of the various target markets and customers.

Aerosol can

Aerobal

Hall 11/ 37

The International Organisation of Aluminium Aerosol Container Manufacturers (Aerobal) will share the stand with the German Aluminium Association (GDA) at Interpack 2017.

“We will be focussing on aluminium’s unparalleled material properties for the production, use and recycling of aerosol cans, of course,” said Gregor Spengler, Aerobal’s secretary general.

“Aluminium cans guarantee maximum consumer convenience, perfect hygiene, the greatest product protection and optimal safety and reliability. They are the only cans that are suitable for almost all types of filling. Aluminium aerosol cans open up a whole host of opportunities with regards design and are unique when it comes to appearance, aesthetics and premium character.”

More than ever before, the focus at Interpack 2017 will be on eco-friendly packaging and sustainability aspects, resource efficiency and trend-setting recycling concepts. It is especially here that Gregor Spengler sees the aluminium aerosol can being particularly well positioned.

Aluminium’s high intrinsic material value provides great incentives along the whole value chain to keep the metal in the material loop and has helped establish efficient recycling systems that use the latest sorting technologies. Aluminium is a permanent material that can be recycled an infinite number of times. Recycling of used aluminium means one only needs 5% of the energy that would otherwise be needed to extract the metal from its ore. Aluminium is thus a real ‘energy bank’.

Spengler said consumers and producers around the globe are increasingly coming to realise that with its high recycling rates, aluminium makes an important contribution to protecting the environmental, safeguarding the supply of raw materials and providing a worthwhile future.

Spengler is also confident that the aluminium aerosol can’s positive assessment with regards sustainability and resource efficiency will further strengthen its position in the global packaging market.

Zero-defect packaging

Heidelberg and Gallus

Hall 13/ D75, E82

Heidelberg and its Swiss subsidiary Gallus will present a range of solutions and measures aimed at automating quality assurance and control, all integrated in the entire workflow and the participating machines in an intelligently networked production environment, under the motto ‘Smart Print Shop – Zero Defect Packaging’ at Interpack. These solutions and measures are designed to boost the international competitiveness of packaging producers by enabling reliable, productive, and economical production, especially of defect-free, high-quality folding cartons and labels in offset, digital, and flexo printing.

“Heidelberg is the leading provider in the industry that can guarantee digitised and industrial packaging production with a defect-free, standardised end-result. Our intention is to continue to expand our offering in this growth market,” Stephan Plenz, member of the management board responsible for equipment at Heidelberg, said.

At Interpack, Heidelberg and Gallus will focus on the question of a colour management system that can span different sites and production methods; and the reduction of complexity, and therefore susceptibility, to defects as well as the means to safely and reliably identify incorrectly printed products without delay and remove them directly from the press or post-press process while production is underway. As part of this process, Heidelberg will show how a zero-defect principle can be implemented across the entire production process, from pre-press through press to post-press.

The integrated Prinect Packaging workflow developed by Heidelberg plays a central role here, by laying the foundations for industrialised production. It enables automation of the workflows – from order acceptance, through structural design, pre-press, and press through to post-press – and facilitates intelligent communication between the areas in order to prevent defects.

Using Prinect as a central business intelligence platform, all the management and production processes in a print shop, including customers and suppliers, can be intelligently integrated and centrally controlled. Prinect integrates Heidelberg’s offset and digital printing systems into one continuous workflow, and offers comprehensive functions for quality assurance and documentation as well as standardization and production of repeat jobs. This also includes the latest versions of the PrinectInpress Control colour measurement system and Prinect Image Control control system as well as the Prinect Inspection Control printed sheet inspection system, which are crucial for defect-free production. The end result is a fully automated and industrialised printing process where manual interventions are reduced to a minimum.

Navigated printing is made possible by Heidelberg’s patented Intellistart 2 software. Automatic processes are autonomously completed in parallel and in a logical sequence insofar as possible. Intellistart 2 automatically calculates the quickest sequence for the job change and reliably and safely navigates the operator through the makeready process.

Plenz said Heidelberg is responding to the demand for serial or even customised packaging and labels with the Primefire 106, the first digital printing system in B1 format for industrialised printing applications, presented at Drupa as well as the Gallus Labelfire 340 for digital label production.

The Primefire 106 features Perfect Stack technology for automatically removing incorrectly printed sheets from the process and immediately and correctly reprinting them. Integrated barcodes and QR codes or even serial numbers can also be added to all sheets for complete traceability.

The Gallus Labelfire label printing system also provides the option of individually identifying entire packages or even the individual label. Inspection systems can be used to register locations in packages with missing labels as well as incorrectly printed or damaged labels so they can be corrected in downstream systems by removing or reprinting them.

Gallus will also be presenting its new process, ‘Metallic Doming’. It can be used to produce raised textures with metallic luster on plastic substrates using rotary screen printing. The result is a haptic sensation that could previously only be produced using hot-foil embossing on paper substrates. Effects of this type are now also possible on tube laminates as well as PP and PE substrates thanks to Metallic Doming.

The Diana Eye offline inspection system uses a reading device or camera to measure the image and contour as well as finishing effects – including coated surfaces, foils, and holograms – in each individual folding carton blank and compares everything against a reference image. Tolerances can be set and deviating results are automatically removed.

Wide width PE films

Synthetic Packers

Hall FG-EAST 15-2-28

At Interpack 2017, Bengaluru-based Synthetic Packers will exhibit its range of PE films for different customised industrial applications. “We are focusing on meat, food and pharma industries,” said Mallikarjun Jamdar, head marketing, Synthetic Packers, adding, “We are the first company in the country to manufacture wide width PE liners up to 5.2m LFT/ 10.4m sheet generally used for pond/ canal lining, dry bulk container liner and greenhouse film.

At Interpack, the company is looking for such customers, along with customers from food and meat industry. “We manufacture customised industrial packing material and export products like high barrier films and wide width PE films. We are a BRC, ISO 9001 and 22000 certified company and are committed to quality. We think we can provide all packing solution to customer under one roof,” Jamdar said.

Set up in 1981, in the last 35 years, Synthetic Packers has built a state-of-the-art infrastructure with latest technologies from around the world to set up multiple plants across India. “We customise the film according to the need of our customer. We have an in-house QC lab which conducts vigorous testing before the material leaves our factory,” Jamdar added. “We are the only company in India which manufactures wide width PE films up to 10.4m. This is our flagship product which is exported to many countries. We also manufacture nylon-based barrier film which is used for meat packing.”

Innovative sustainable packaging

Sappi Packaging and Speciality Papers

Hall 9/ D19

Sappi will present its innovative sustainable packaging solutions made from renewable raw materials at Interpack 2017. At the show, the global supplier of speciality papers and boards will showcase efficient ways and possibilities to take advantage of packaging trends to meet the growing demands to deliver the packaging of the future. Of particular interest in the Sappi stand will be the world’s only packaging papers with integrated barrier and heat-sealing properties. In addition, the company will present innovations and packaging solutions for containerboard, rigid packaging, label papers and flexible packaging.

Four years ago, Sappi was the world’s first manufacturer to present an innovative speciality paper with a mineral oil barrier and heat sealing properties integrated directly into the paper. Since then, the Sappi Guard product range has been continuously expanded with additional high-barrier paper-based solutions. At Interpack 2017, Sappi will present more new developments in the field of multifunctional barrier papers for food and non-food packaging, including the initial results from the recently announced collaboration agreement between Sappi and Felix Schoeller. Both companies have unique competencies in their respective business segments and together are focusing on highlighting sustainable and high-quality alternatives to current packaging solutions with their future products.

The Fusion virgin fibre liner from Sappi was the pioneer in the field of white coated topliners for corrugated board. Thanks to the use of bleached virgin fibres as the raw material, these topliners also offer visual benefits as well as considerable strength advantages. They achieve approximately the same material strength as test liners, with a lower weight per unit surface area. When the total cost of ownership (TCO) is considered, as companies are increasingly doing, the virgin fibre liners represent a real alternative to the double-coated test liners that are most commonly used. And this will drive greater demand. To meet that demand, Sappi has expanded production to a second production site in Ehingen. At Interpack, Sappi will present new paper weights for its Fusion Topliner.

Sappi will also presenting its multi-award-winning bright white solid bleached board, Algro Design, displayed in a variety of applications. This board is generally used for demanding folding box applications, especially for cosmetics, perfumes, beauty and healthcare, fine chocolate and confectionery packaging, as well as fashion and lifestyle items, luxury drinks and for outstanding graphic applications.

With its Parade product line, Sappi offers a comprehensive range of facestock and wet glue label papers for a variety of processing options. At Interpack, Sappi will launch a new facestock label paper in the form of Parade FS, which is suitable for use in self-adhesive label applications such as stickers and price tags. Parade FS can be printed with offset, flexographic and gravure and laminated. Thanks to its excellent surface properties, the glossy paper, coated on one side, ensures a brilliant appearance and excellent print results.

Also at Interpack, experienced packaging specialists from Sappi will discuss potential packaging concepts with visitors. “We are the expert and reliable partner when it comes to challenging packaging solutions,” said Thomas Kratochwill, vice-president, sales and Marketing, Sappi Packaging and Speciality Papers. “In light of the high investment levels and significant amount of work that Sappi has put into packaging and speciality papers, we will be offering even more surprises to visitors at our Interpack stand.”

See All

See All