|

Survival of print business now depends on value addition, particularly in a city like Kochi in Kerala, where every quarter there are two or three new digital printing machines installed in every nook and corner. “However, digital printing is growing. Only we can’t feel it because the jobs are now getting distributed,” said Gerard Chandy, the managing director of Jerry’s Printshop, popularly known as Jerry. “We have kept pace by adding two new centres in the city.”

Jerry’s is a dominant print company in the Paramara Road area of Kochi. The digital print specialist’s print shop has a battery of three Xerox digital presses – a Color 1000i at the Paramara Road centre, which is also its head office, installed in 2017; the other two presses, a Xerox Color 1000 and a Versant 2100 at the two centres, to cater to a large category of walk-in and corporate clients.

The company is also equipped with a raft of post-press solutions to meet the value-add requirements of its customers.

“We have always been ahead of the curve in putting our money on the right technologies. We demand technologies which will help us differentiate our offering to customers. Precision is an important factor in a set of things that we evaluate. And all of this has to be provided at the lowest possible turnaround time for the customers and the fastest ROI for us. Such a set of demand has worked for both – customers and us quite well,” said Jerry.

Jerry’s produces a maximum of 1.5- to 3-lakh prints per month, the higher number during peak season. In 2017, Chandy realised that merely selling sheets will not be a profitable business in the future. It had to add value to the prints. So when he saw the Duplo DDC 810 at TechNova’s stand during Pamex 2017, he knew this was the kit he was looking for.

Jerry said, “We were impressed with the compact size of the device. Since we had known Duplo’s paper handling consistency in their finishing solutions, we were sure about registration capabilities. But frankly, we didn’t expect TechNova to introduce such a digital post-press solution.”

Jerry’s became the first installation site for TechNova for its digital enhancement solution powered by Duplo DDC 810 along with UFX. “TechNova’s presence was a great motivator for us to start evaluating DDC 810 for our digital spot UV and foiling needs,” said Jerry.

When the PrintWeek India team visited the shopfloor dominated by a Xerox Color 1000i, the tight space in which Duplo DDC was operating was an impressive sight. DDC 810 covered 8x10 sqft of space. The first thing the operator told us was that the installation, and machine uptime was the shortest that he had seen. B Rajeev, TechNova’s senior manager for digital imaging solution, informed the PrintWeek India team that the unboxing to churning out the first print was less than a day. “In the truest sense, DDC is a plug and play device,” he said.

Today, 80% of jobs go out finished, said a beaming Jerry. “The offline foiling has a unique advantage of giving us the flexibility of creating multiple combination passes of foil and UV and toner prints. We can create unlimited coloured foiling through this foiling unit. The registration repeatability is outstanding compared to any of the alternatives that we have evaluated. Duplo DDC 810 barcode and VDP features are handy,” said Jerry.

Going ahead, Jerry’s customers, which included creative agencies and small food, cake and bakery producing entrepreneurs, started coming in with low quantity packaging requirements. He started looking out for a kit that could cut-and-crease without him have to make dies. “It’s a time-consuming process, which would put the customers off,” said Jerry.

The next thing, Jerry installed a small automatic feed digital cutting table from TechNova powered by JWEI. “What took two days to produce, was now produced in 30 minutes.”

And now that Jerry’s customers know that there’s a facility which can deliver a finished product for the kind of creative design they produce, its packaging volumes have increased. “We produce around 25 jobs of 50 sheets each now. During peak season it can go up to 200,” said Jerry.

Initially, Jerry’s had to compromise on the pricing because, Jerry said that the new capability had to be promoted. “Once they got used to it, it became an inevitable part of their buying process.”

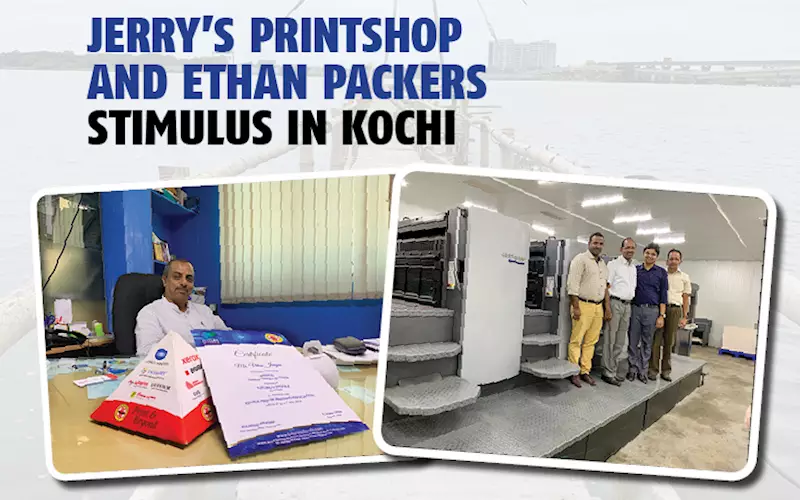

(l-r) Rajeev of TechNova with Gerard Chandy of Jerry’s Printshop

Jerry quoted a print job he produced during Christmas. He deployed both the Duplo and the JWEI kit to produce a digitally finished paper lamp box depicting the birth of baby Jesus Christ. “It was one of our hot selling products,” he said.

“Normal digitally printed sheet or simple print product does not create the wow factor a digital spot UV, foiling, cutting and creasing can. Customers are willing to pay a higher price now. That’s where the real value of a business is – bigger margins,” said Jerry.

While Jerry is contemplating investing in a bigger JWEI kit, Rajeev of TechNova is delighted with the success of the two kit at Jerry’s. He said, “We wanted to have our first Duplo DDC 810 at a site where we can try the limits of the machine. Then there’s the JWEI success. TechNova is happy that it has helped Jerry’s differentiate in this crowded digital print market far better compared to any low-end or high-priced competing devices. Our strategy is simple – customer first.”

Ethan Packers has huge ambitions for Grafiqe Printers, its new printing arm

Ernakulam-based Ethan Packers was set up in 2011, initially to support its parent brands’ packaging needs – Marriboy, a fresh ice-cream brand and a plastic moulding business. Meriiboy, which was established in 1990 is one of the largest producers of fresh ice cream, based in South India. Ernakulam-based Ethan Packers was set up in 2011, initially to support its parent brands’ packaging needs – Marriboy, a fresh ice-cream brand and a plastic moulding business. Meriiboy, which was established in 1990 is one of the largest producers of fresh ice cream, based in South India.

The packaging converter, managed by four partners –Lito Baby, managing director, and MD Stephen, ME Verghese and Lijo Baby, all three as directors – eventually had to set up a printing vertical. According to Stephen, the decision was driven by the pressures of production and competition.

“We faced production bottlenecks because we could not control deliveries of our print requirements, which was largely outsourced,” said Stephen, the youngest of the four partners. “It was a difficult decision because the printing industry was not in great shape, but we had to.”

Ethan Packers began with a humble converting line comprising one manual die-cutter, a lamination machine, and a folder-gluer in a rented space. Initially, it produced packaging cartons for its parent company’s ice-cream business, but later also took up jobs for customers in the food, spices, and apparel businesses. “We had to fill unutilised capacity. It was more of a converting unit,” said Stephen.

In 2013, Ethan moved into its own 6,000 sqft site factory in Kizhakkambalam, which was further expanded to 12,000 sqft in 2017. “All along, we kept on adding more equipment like a liner-carton machine for packaging spices, few more manual die-cutters, and lamination machines,” explained Stephen.

In 2019, when it decided to set up its printing unit, it established another plant a little away from the converting unit, in Kinfra Industrial Park. It was named Grafiqe Printers.

(2nd from right) Stephen: “Our next goal for Grafique is to set-up a plant outside Kerala by 2022”

Stephen described his customers as a mix of big FMCG as well as small local enterprises. “Of the entire printing business pie, our captive business is 10% each in ice-cream and moulding. The other 80% of the jobs are outside work, which also includes our competitors in the ice-cream and moulding segment.”

So when Grafiqe was to be established, Stephen along with the partners did market research on how to go about investing, such that it will not take too long to break-even. “We weighed all options – RMGT, Komori, Heidelberg; two- or four-colour or more; new machine and old. We did a thorough market check, spending around Rs 5-lakhs. We took one year to finalise on what we should go in for or do, whether the packaging industry can sustain the printing industry, etc.”

Grafiqe installed an all-Heidelberg kit – a remarketed Speedmaster CD 102 6+L, a brand new Suprasetter A 106 platesetter and a Polar 115 PF cutting machine. Lito Baby, the managing director, said, “We were looking for a press which can run boards for the packaging purpose we had in mind. A brand new press of the configuration we were looking for was a little out of our budget. We got feedback that even a used press can deliver quality print. Heidelberg was willing to give us a good warranty. We zeroed on this Heidelberg 2009 make, which is as good as a new press.”

The press was installed towards the end of June, and in a month, Grafiqe has converted 200 tonnes of paperboard. “Our customers are happy with the quality,” said Baby.

Besides advice on the press, Heidelberg provided Grafiqe with all support in terms of opinion on the foundation required for installation, CTP and the software required. “As Heidelberg was acting as a full-service provider, we decided to invest in Heidelberg’s CTP, a cutting machine, and the Pro Man software, all in one basket,” said Baby.

Stephen added, “As a start-up firm, we did not want to compromise on quality and the subsequent blame game between the manufacturers and suppliers of consumers. Now that we have all the print-related equipment from one company, there will be no blame game.”

Stephen aims to establish Grafiqe as a reputed print packaging company. “We have a good team, capable of pitching to good customers. Word of mouth publicity is always the best marketing technique. Since we are present in multiple industries, we hope to get customers through references.”

By 2022, Stephen plans to set up another plant out of Kerala. “That’s our next goal for Grafiqe Printers,” concluded Stephen.

Heidelberg India’s take on the investment

Speedmaster CD 102: A top-preference among packaging printers in India, the CD 102 is referred to as the all-rounder. The Speed master CD 102 can handle a range of substrates from 0.03-millimetre paper to 1 mm thick cardboard (0.0012 in - 0.039 in) with a production speed of 15,000 sheets per hour, and for Grafiqe it is a perfect choice for packaging printing.

Suprasetter A 106: The Suprasetter is a high-performance pre-press equipment which complements the CD 102 5+L press. Suprasetter A106 can produce up to 18 plates/hour in sizes ranging from 370x323mm to 930x1140mm. Equipped with unique thermal laser technology developed by Heidelberg, the plate-setters are almost totally insulated against production failures by the Intelligent Diode System (IDS).

Prinect Production Manager (Pro Man): With Pro Man, the press and pre-press are integrated seamlessly. The workflow has all the features which a printer needs for packaging and commercial printing right in pre-press, press and post-press areas. This can also be scaled up in the future, with related add-ons. All of this is available with a flexible payment system.

|

See All

See All