Kalim: The unsung hero of print

Krishna Naidu narrates

09 Mar 2016 | By Krishna Naidu

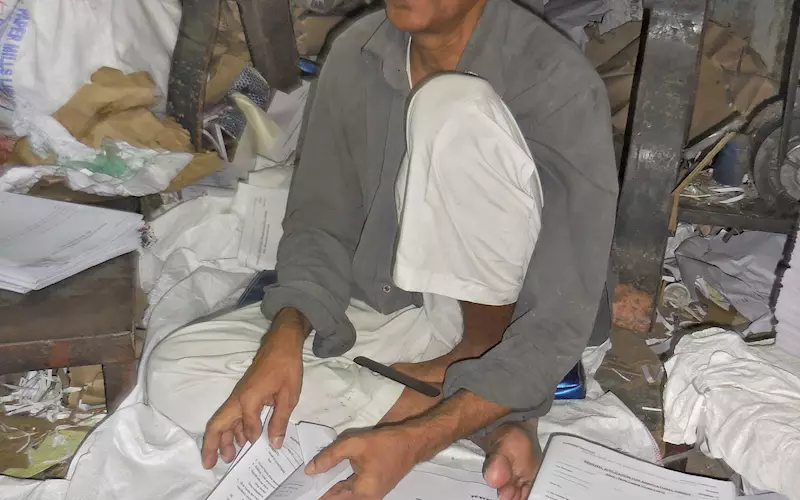

Kalim Iftikar Shaikh, one of the proprietors at M K Stationery and Printer in Parel, Mumbai, loves what he does at the press. Kalim, who works on a semi-automatic cutting machine and having the knowledge of working on the binding machine, undertakes multiple jobs including binding registers. But when Kalim begins his work at the press, the clients and people who visit the press are often astonished seeing him pull the handle of the cutting machine at the press.

In extension of working in a printing press, Kalim is visually impaired.

Kalim, says, “With the semi-automatic cutting machine, I am able to work and cut the same amount of material which is being cut at other printing presses. Working on a machine that does not have many spots and taints and complications, it’s his source of income.”

Kalim has completed his training in electric machine making, aluminium making, paper bed-making for two years at the National Association of the Blind (NAB), Worli and shares regular updates about his activities with his friends at the association.

The paper cutting machines, with the amount of risks involved, may not seem like the best job for

the visionless people. People, who are visionless, trust more on their hearing ability. They can determine the denominations of currency notes by their super tactile ability of touch and recognition. The National Federation of the Blind provides such solutions for the visionless people.

Kalim, says, “Now, even if you are visionless, you can do all types of work and achieve a lot.”

Later when Kalim wanted to start his own stationery business with his two brothers, Sarfaraaz, handling all the packing work at the press and Ibraar, who looks after overall work at the press, Iftikar, Kalim’s father and the family stood by his decision. Iftikar being a ticket collector at Brihanmumbai Electric Supply & Transport (BEST) Undertaking, encouraged the decision for the stationery business.

In January, 1984, Kalim got a license for the press and started working at MK Stationery, which later became MK Stationery Printing Press. The firm has been undertaking jobs from State Bank of India (SBI), as a registered contractor on the tender basis. Kalim at the press also prepares the quotations, labour chart, finalises on the bank rate at which the quotation has to be sent for approval.

In 1997, Kalim with his family’s assistance bought a new single-colour offset, black and white printing machine at the cost of Rs 4-lakh. The machine handles the size of 14x18inch. The machine is still running strong. Only for major breakdowns are the technicians called for servicing the machine. Small issues related to the press are sorted by Kalim and his two brothers.

Kalim used to stay in Parel, in the same building where the press is currently located but now he is had shifted to Mira Road, Mumbai. While some of the companies might have generous goals in supporting and giving opportunities for those who have lost sight, there are many Kalims who are challenging their ability to survive in the real world.

According to the data of Blind Foundation, one of every three blind people in the world lives in India, and around 15-million visionless people live in India. There are around two-million visionless children in India and only 5% of them receive education.

Ibraar, the younger brother of Kalim, says, “In the printing industry, there are very few persons with visual impairment and I am proud of what Kalim is today.”

According to an article in the Indian Express dated 1 September, 2014, “Still there are 45-million visually challenged people from India.”

On the daily basis, Kalim takes breaks for tea, lunch and namaz at the mosque; devoting most of his time to the press. He works from 9 am to 6 pm. In terms of educational qualification, the younger brother, Sarfaraaz, has completed HSC, Ibraar with SSC and Iqbal after completing his master degree in science from Ruparel College, Mumbai, has settled in Sharjah, UAE, handling a chemist business.

MK deals with printing in letterhead, forms printing, debit and credit slips for SBI in Maharashtra; answer booklets, question papers, school calendars for Anjuman Islam School. The press also prints the annual report for Navbharat Vidyalaya, Bhoiwada. At M K press, the clients are SBI, Navbharat and Anjuman Islam School and the plates are supplied by Parker Studio, Dadar.

Annually, M K has paper requirements of 10 metric tonnes and Gala Paper Mart and Reliable Paper Mart, Girgaon are the supplier of paper to the press.

There are four persons MK employs, with the three brothers as proprietor and one printer for heavy duty work. The turnover of the company is Rs 20-lakh annually. As far as labour issues are concerned, Sarfaraz, said, “We are not dependent on labours as most of the work is done by us.”

Talking about the print industry in the city of Mumbai, Sarfaraaz, said, “Print is the same as it was in 1997, the rate and cost of margin in print industry has come down. There is a growth in IT, mobile and other digital mediums and this has only made our working process smoother, but the rate of returns has become very thin. There are clients who still want to execute work at old rates. But if we follow the same old rate every year, then what kind of return of investment will we have?”

Sarfaraaz adds, “Issues like light, raw material and the cost for materials at the press is increasing by the day. The government too is turning a blind eye to printers like us.”

Ibraar, says, “No one looks at the rate at which the loan is given by the bank. The rate of interest should be more for big daddies and less for us. The amount of interest charged to us and to the big players is the same and I think this is not correct. There is no financial support from the customers and the bank. There should be a system made by the government and should be followed by all.”

Sarfaraaz butts in, “We live in a digital age, an age of paperless environment. This has affected the printing industry. Earlier, all the small types of jobs used to come to us from the clients, for example, leaflets printing to wedding cards printing. Due to digitisation, there are less printing jobs available and most of the small printers are shutting down their business.” Sarfaraaz also handles all the packaging related jobs at the press.

Kalim concludes, “The quality of the paper is the same, but the cost of the paper has risen by 20% as compared to past 15 years. If we speak of one change in the printing industry, the thinking should be changed in offset printing. There is a difference between a material being printed at a local photocopy shop and at the printing press. Today, the value is more for a print at a photocopy shop as compared to an offset printing press. The customer thinks that the cost of investment is the same in a photocopy shop and at a printing press,”

See All

See All