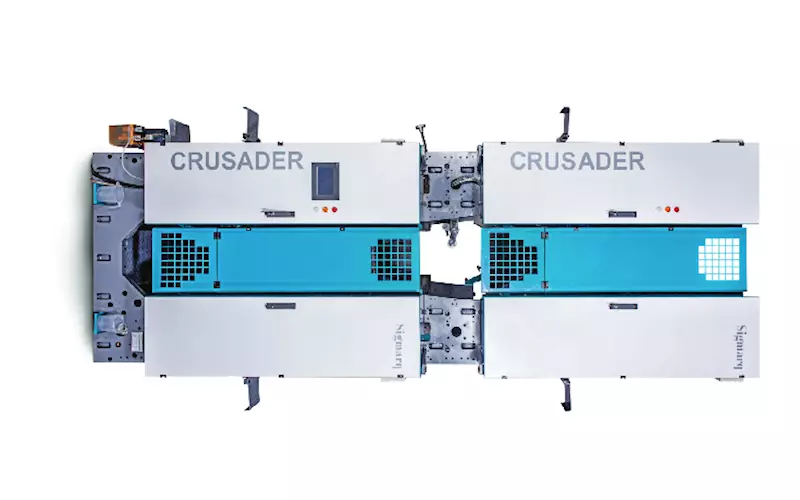

Made in India: Crusader from Sigmarq Technologies

Kolhapur, Maharashtra-based Sigmarq Technologies has developed the Crusader brand, where printing towers are based on the blanket-to-blanket principle to print on both sides of the paper. Rahul Kumar gets the details from the company’s managing director Rajesh Ghorpade

03 Oct 2018 | By PrintWeek India

The Crusader model of web offset presses has been developed by Kolhapur, Maharashtra-based Sigmarq Technologies, spearheaded by Rajesh Ghorpade as managing director and Pradeep Shirale as executive director. Sigmarq has designed this model based on 4x4 printing with cylinder arrangement on ‘arch and reverse arch’ principle. The machine can print 40,000 copies per hour.

“Our printing towers are based on blanket-to-blanket principle to print on both sides of the paper. It is offered in either the H unit format, bearing the printing capability of 2x2 colour printing and when two such H units are stacked on each other, it produces 4x4 colour printing on the either side of the paper passing through this type of 4-high printing tower,” says Ghorpade.

According to Ghorpade, the trend nowadays is moving towards all four-colour pages in newspapers and therefore, controlling web tension and colour registration has become a crucial factor for printing operators. “Thus, this type of tower construction gives stable print register as compared to the earlier style of placing 1x1 or 2x1 colour units in line and increasing the web path,” he explains.

He also adds that the earlier combination would occupy more space, but Sigmarq’s 4x4 vertical towers integrated with autopasters save space substantially. At the same time, it helps operators achieve improved colour printing.

The Crusader model was launched in 2014.

For Indian newspapers

Ghorpade says the machine is suitable for all mid-circulation newspaper printers and publishers and for those who are moving into the large circulation category. “It is best suited for newspapers with a daily circulation of 80,000 to 1,20,000 copies, that too with seven to eight editions,” he says.

Ghorpade adds that the Crusader is equally useful for textbook printers.

In the context of India being a price-sensitive market, Ghorpade says while cost is always a concern for the buyer, nowadays, most buyers look beyond the machine cost and look at overall benefits, such as quality, productivity, ease-of-operation and after-sales service support.

“Against this backdrop, right from its inception, Crusader has created its own identity,” Ghorpade says, adding, “As far as meeting the delivery commitments are concerned, we have steadily geared up to expand our set of vendors and sub-suppliers and have increased the per month production output at our end. This is helping us meet deadlines put forth by our customers.”

Ghorpade says while India has been the primary focus market for Crusader, the company started selling the machine in Kenya three years ago, where it’s being used for book printing. Encouraged by this, Sigmarq is now exploring other African and South East Asian countries.

In India, Crusader is running in newspaper production plants such as Dainik Jagran; Daily Thanti; Eenadu; Gujarat Mitra; Dainik Vaarthaa; Elegant Offset Printers (a franchise printer for The Times of India) and Dangat Media.

Making web offset work

Ghorpade says the most important aspect of web offset printing market is cost, subsequently followed by reliability, dependability and productivity. However, it’s important to consider all these aspects together instead of looking at one aspect at a time. “For example, if you just focus on cost, there is a fear of sacrificing the other three factors and this will eventually jeopardise your brand value. We always try to balance these four aspects to the extent possible.We strongly believe that in the long run, it’s better to honor our own commitment, rather than winning an order just for the sake of business,” he says.

Sigmarq produces all key aggregates of its machines, such as printing towers, folding units, reel unwinders as well as autopasters and all other utilities, indigenously under one roof. This, Ghorpade says, has helped control the cost.

And so, the company is not concerned with competition. “We compare our performance with that of ours only and are not worried about what others are doing. As we see, the trend is slowly moving towards utilising the offered configuration, not only for printing of newspaper editions during the night shift but for some additional print runs during day time as well. This is mainly for increasing OEE (overall equipment effectiveness) of the configuration,” he says.

Keeping this trend in mind, Sigmarq has frozen the specifications of Crusader. “We have additionally kept provisions for accommodating add-on utilities, which a customer may consider while increasing the effectiveness of the configuration,” he adds.

Crusading for effectiveness

Time is the essential ingredient in newspaper printing. Print schedules, comprising of various editions, have to be maintained every day, that too in no uncertain terms. Ghorpade says the company has been successful in meeting this requirement with its complete support to client’s operating crew, literally round-the-clock. This is in addition to a structured on the job training imparted to the operating crew, during the commissioning of the presses.

Meanwhile, Shirale says Sigmarq can list remote ink control with segmented ink blades, spray dampening systems (replacing existing conventional dampening methods), gluing at the spine of the folded signatures, inline numbering systems, automatic web threading system and so on.

Crusader is designed with more working space, and due to the smartly arranged positions of printing cylinders, it has succeeded in avoiding operators’ cumbersome postures while plate loading and unloading. This has largely helped in quick plate changeover during edition change.

Again, with interfacing of its ink zone control system communicating with the pre-press via CIP-3, ink density control of the respective colour station is attained within no time and that reduces the print waste noticeably. At the same time, the printing tower integrated with the splicer ensures shorter web path and guarantees reduction in the start-up waste.

With the provision of the precise web tension controls at outfeed and infeed, the web tension is maintained properly, thus assuring no variation in the cutoff margin and print register values even when the press speed is increased or decreased for any reason by the press operators.

Total solution provider

For the last couple of years, the company has started offering its services as a total solution provider, even to the machines of other make. Recently, Sigmarq successfully converted one conventional press produced by an overseas manufacturer into shaft-less operation. Similar to this, the entire control system of an autopasters supplied by another overseas manufacturer was recently replaced with the latest Electronic Control System.

“Since we possess the basic knowledge of all the engineering, electronic and press automation related needs of the newspaper printing machinery to the required extent and have been regularly updating it, taking over any such challenging tasks has become quite easy for us.

A group of our specialists is always on the move to undertake such challenging tasks and day-by-day our span and strength in this arena is snowballing,” Shirale adds.

How Eenadu used Crusader

Ghorpade gives the example of Eenadu publication in Telangana which used Sigmarq’s offering of infrared (IR) drier vertically placed on the top of the Crusader tower, for converting it into a heatset semi-commercial application. The tower is designed and positioned to run in tandem with the heatset commercial press supplied by the overseas producer.

Ghorpade says, the client was exploring the possibility of mounting UV driers on the printing tower.

“However, looking into the hazards, we suggested IR drier. Also, the higher cost of UV inks and rubber rollers and the demand of dedicating a printing tower for UV inks usage was quite prohibitive for the client,” he says.

Thus, Sigmarq offered three Crusader towers with infrared drying systems, custom-built with the latest heat emitting Quartz technology IR tubes. All these presses, located at three printing plants in Andhra Pradesh and Telangana are used for four-colour magazine printing.

Best practices

Says Ghorpade, “We believe in documentation, overall cleanliness and quality assurance related initiatives at every stage of manufacturing our products. We believe that if we do not address all these aspects relentlessly, we will not be able to provide our products and services to satisfy customers’ expectations.”

Looking ahead

For the current year, Sigmarq is aiming at a production target of minimum 50 printing towers and a suitable number of folders as well as splicers. “From the next fiscal year, we will be adding other models and utilities in our fleet,” Ghorpade says.

According to him, the best business model is to equip oneself to providing a total solution based on the single window concept.

“We are seriously working on this model and are slowly expanding our scope of activities rather than restricting ourselves to manufacturing of machinery alone,” he adds.

Towards this end, the company has been working on launching a brand new 50,000 cph press in the coming year, called Maximus. “This model will be technologically advanced, so as to meet the demands of the customers, when they want to increase the output capacity of their running presses,” he concludes.

See All

See All