Orange Planet at the Bindwel stall

Bindwel at Drupa 2024 is highlighting the future of bookbinding. Its mantra at the show is 7 out of 10 books produced in India have been touched by Bindwel machines, services, or adhesives. To celebrate this achievement, Team Bindwel has been showcasing the innovations and advancements by Indian book print firms that have shaped the industry. Do read the profile of Thiruvananthapuram-based Orange Planet.

04 Jun 2024 | By Charmiane Alexander

Who: Orange Planet (a leading educational publisher who has in-house printing and in-house bindery in 2000)

Where: New Delhi (50,000 sq/ft with 25 machines). The Touch Pad series (computer books till K 12) is a hot-selling product of Orange Planet.

What Orange does: Printing books for educational publishing houses. Orange prints about one-crore books during the educational publishing season. Even when we print a book just-in-time and deliver it to the market, it becomes a best seller for us.

The most complex book that Orange has produced: Junior Artist which has lots of paper and ingredients used to manufacture this book. The size is 9-in x 11-in and it's tough since it needed lots of material to make it like paper board, cotton, foil paper, goggle eyes, tissue paper, ice cream stick, earbuds etc.

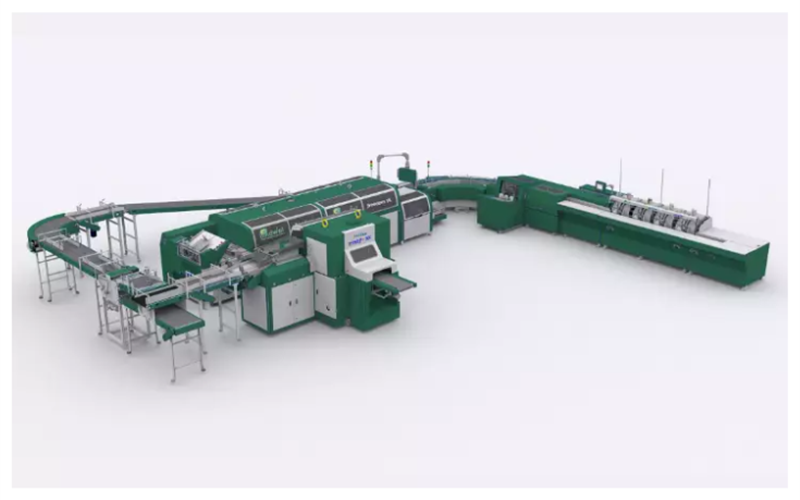

How Bindwel boosted Orange books: With the help of Bindline 5000, we could fulfil the demand on time.

What does the Bindline 5000 do? It is a complete end-to-end inline binding machine with 16 station-gathering, Freedom 5K perfect binder, conveyor and Trimit 30 C trimmer.

When was the Bndline introduced at Orange and what markets is it intended for? In 2023, we intend to capture a major share of the K12 market. Publishing is changing, and we need customisation, just-in-time delivery, and coping with the syllabus changes. Also, we need print-on-demand when our distributors run out of copies. So our printing and binding equipment should be designed for challenges

How does it work? In the beginning, we had challenges moving our offline operations to inline, but the Bindwel service has been exemplary. The Bindwel team stood with us, trained our team, and taught us dos and don'ts. Ultimately they made us proud about our decision. With their help, we have moved most of our jobs from thread-sewn to perfect binding. Also, we have built a lab that includes the Bindwel page-pull tester which helps us inspect each batch of books before they are sent out.

What is the USP? Throughput is excellent, it is easy to operate and reliable. Plus it is backed by the well-known Bindwel support.

Is it easy-to-operate? The system is operator-friendly.

How does the Bindwel team fill the gap between pre-press and dispatch? When it comes to perfect binding we have trust in Bindwel. Their team is very supportive and they always ensure we excel and deliver the best.

See All

See All