Picture Gallery: Balaji Multiflex’s Rs 120-crore flexible packaging factory

A dream project and a relentless two-year pursuit in setting up the 2,50,000 sqft greenfield factory at Amreli in Rajkot, has made Balaji Multiflex one of the most-modern and sophisticated flexible packaging plants in the country

19 Oct 2018 | By Rushikesh Aravkar

Rajkot-based Balaji Multiflex was established by Chandrakant Bhalara (l) in 2002. Today, Pranav Bhalara (r) helms Balaji Multiflex along with this father Chandrakant

The company has spent Rs 120-crore to set up a greenfield project. The cornerstone of the factory is the India’s first W&H Heliostar II gravure press

The new W&H Heliostar II at Multiflex is a nine-colour rotogravure press. Two prominent specs: it is a 1,400mm wide machine and it boasts a maximum printing speeds of 500 metres per minute

W&H Heliostar II S rotogravure printing press

The company has also backward integrated with a new 2.8-metre wide W&H Varex three-layer blown film line. In picture (l-r): Pranav Bhalara of Balaji Multiflex, Anuj Sahni and Vineet Gupta of W&H

“Heliostar was my dream but my love was Varex. More than engineering, the machine design is remarkable,” says Pranav Bhalara (l). His cousin Nirav Bhalara oversees the Varex line

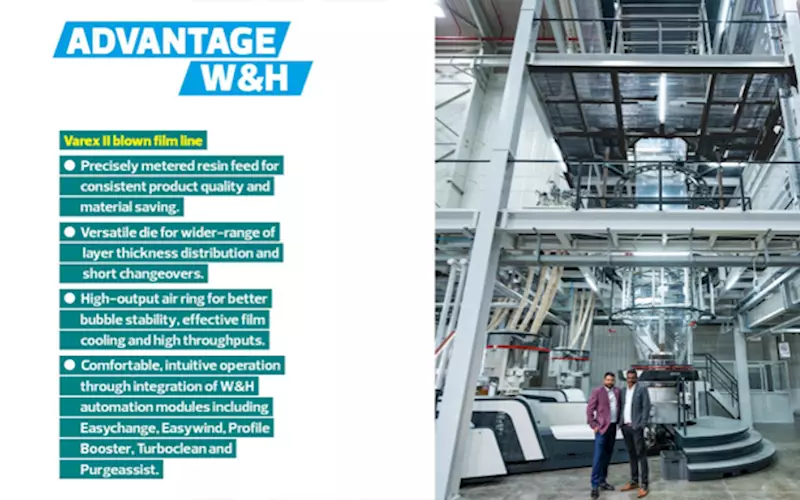

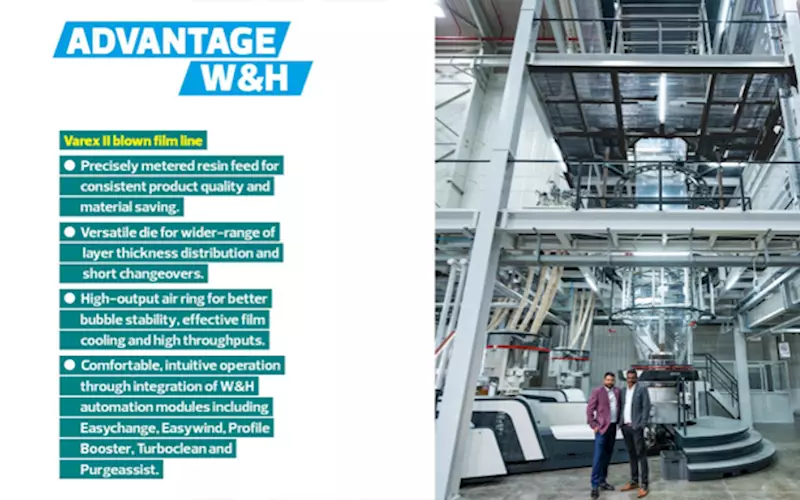

W&H Varex II three-layer blown film line

Since 2015, Balaji Multiflex has been using non toluene non ketone (NTNK) inks. "Even ketones are carcinogenic. We supply to food companies. So we started using NTNK inks from Hi-Tech Inks and Flint"

To read Balaji Multiflex’s growth story and its vision for the future, get the latest edition of WhatPackaging? magazine. Write to ganesh@haymarketsac.com

See All

See All