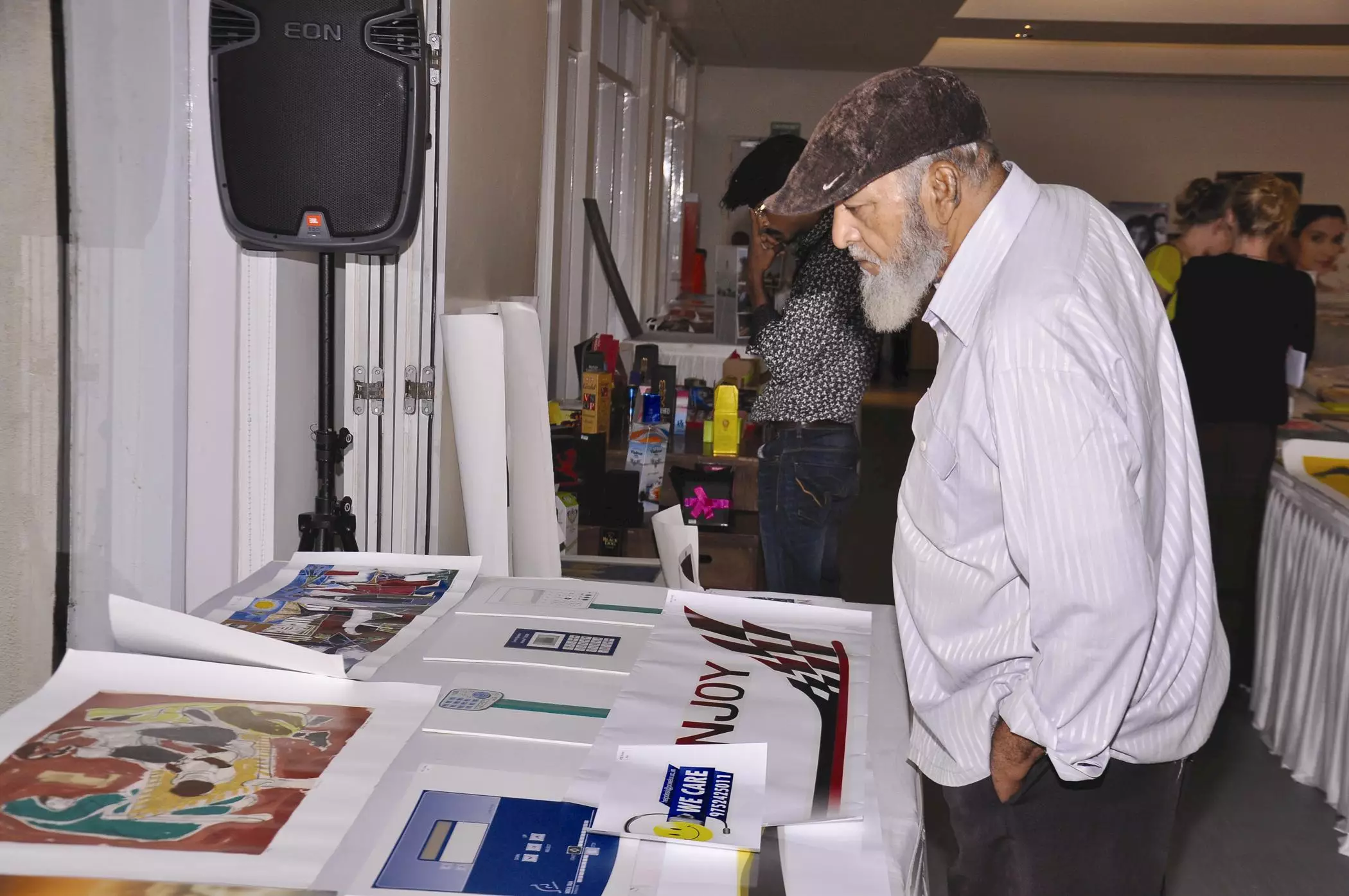

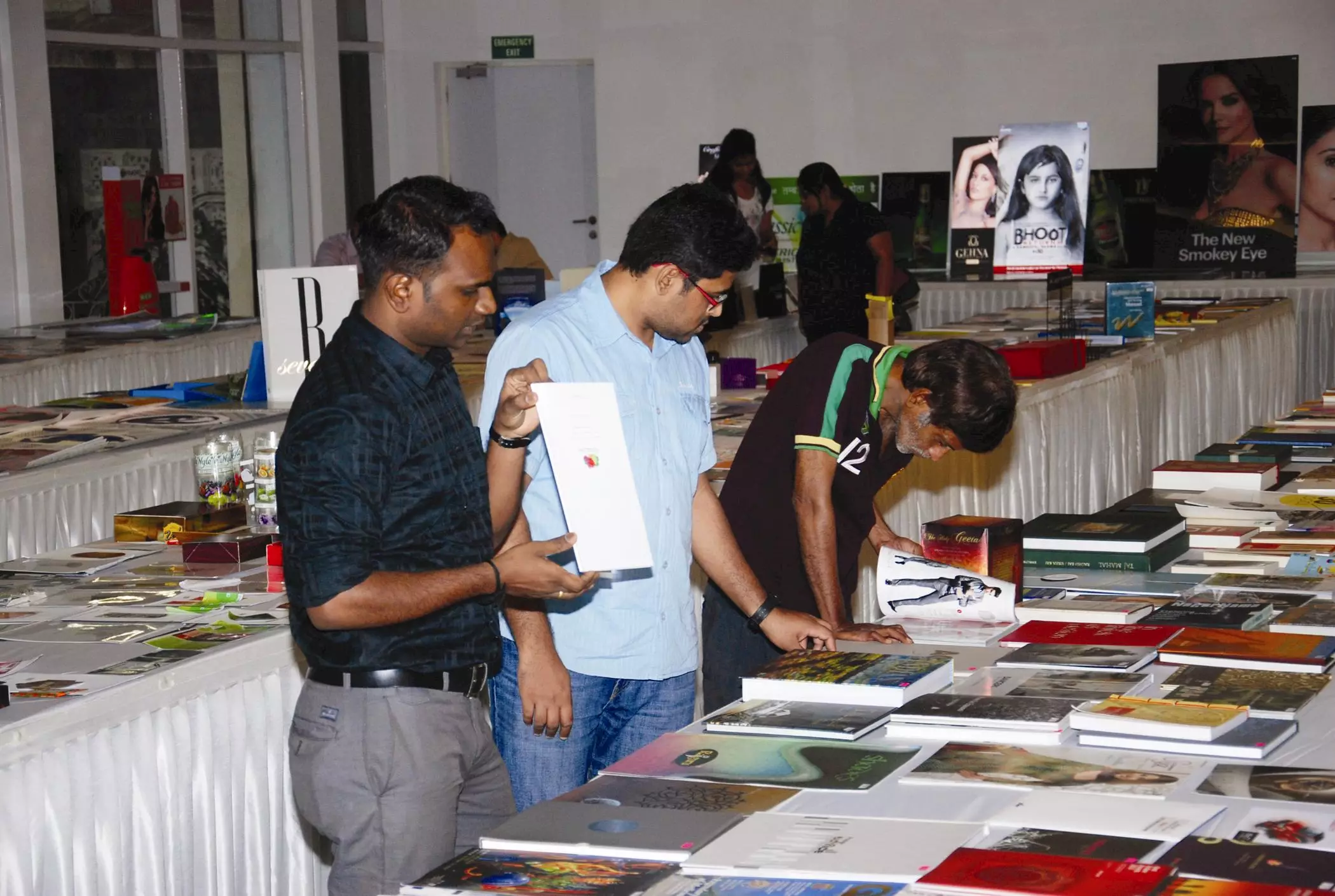

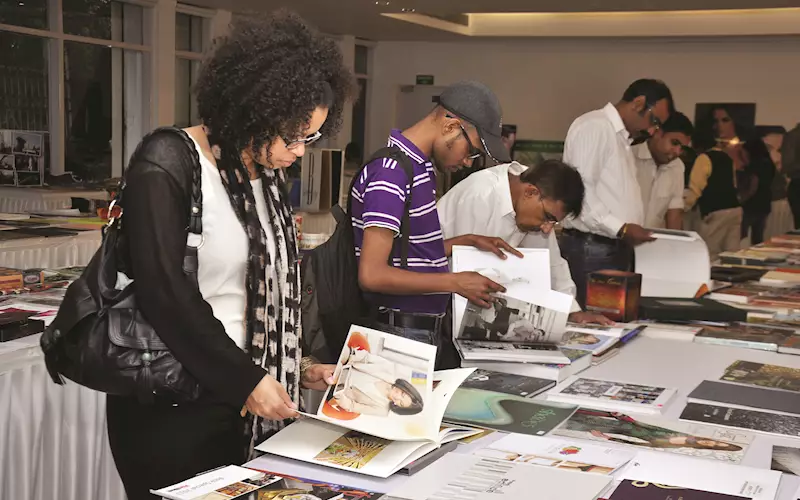

Print buyers go gaga at Print Fair

PrintWeek India with Max Mueller Bhavan Mumbai hosted Print Fair to showcase the depth and breadth of print work and print ideas. On day two, six print firms showcased their work for ad agency designers and print buyers. A report.

21 Nov 2013 | By PrintWeek India

“Just-in-time demands are the movers and shakers for the digital industry,” says Sunil Chhugani of PODS

Sunil Chhugani, managing director at PODS, showcased the power of digital printing in his presentation at the ongoing Print Fair at Max Mueller Bhavan Mumbai.

Touching upon the three core contributions of the digital technology, Chhugani said, “The digital technology is here to play its role. Digital as a technology has expanded the array of special effects that can be added to a product, it facilitates publishers and packaging printers and also permits personalisation, a trend which is here to stay for long.”

Chhugani showed the audience print samples with dimensional printing, printed on the Kodak Nexpress. “We have used the fifth unit on the Nexpress for 3D effect on the images, to highlight certain motifs, create a raised effect and also for effects like watermark, which act as a security feature.” He added, “The ability to produce a product which cannot be scanned or duplicated is digital printing’s contribution to security printing.”

“We have had brands which approached us demanding prototypes as few as 10-50 and that too, overnight. We have publishers who opt for a pre-run of 50-100 books to help them gauge the response of the readers; this trend is fast picking up with the self publishers.”

According to him, the continuous changes in fashion, and the ever-increasing wedding industry in India, are instrumental in driving the demand for digital printing. “Personalisation is the most preferred by individuals, across gift articles, wedding cards and corporate statements.”

Chhugani emphasised the role of design, stating it to be an integral predecessor to printing.

“Designers need to explore more to enable the printers to use the available technology at its optimum. At the crux of producing an excellent printed product is the design and the knowledge of the capabilities and limitations of the equipment.”

As Chhugani puts it, “The print-on-demand model, with shorter runs and quick turnaround time, is the crux of the digital technology.

Pragati showcases 3D books and calendars at Print Fair

Navin Dhanani of Hyderabad-based Pragati Offset showcased the Pragati Calendar and the 3D books produced as a part of their show and tell presentation on innovations during the second day of print fair at Max Mueller Bhavan Mumbai.

Speaking about the 3D books, Dhanani said that more than printing it is the photographic effects which make the 3D books. “When you see the book with the goggles provided with the books, you are able to see the images in a three-dimensional space,” said Dhanani.

Dhanani also showcased the samples of Pragati Calendars. “The calendar features various processes ranging from embossing, punching, micro-embossing, foiling etc,” said Dhanani.

PrintWeek India Printing Company of the Year 2013, Pragati Offset holds the distinction of being the most awarded print firm in India. The Hyderabad-based print firm has placed India on the international map of printing excellence.

“Designer Books are the Rolls Royce of the book world,” says Aspi Forbes of Jak Printers

Presenting to an audience of 60+ delegates, Aspi Forbes of Jak Printers, chose to present a case study of an eight-year old book they produced.

The book, Lights. Camera. Masala., has to its claim a gold medal and the title of the ‘Best Designed Book’ at the New York International festival.

“The credit for the book,” Aspi said, “goes to the designers, Divya Thakur and Sheena Sippy and team Jak.

Jak, who has established a solid reputation for its uncompromising stand on quality, considers designer book production as an art which amalgamates the expertise and passion of both the designer and the printer in question. “Designer books are similar to designer cars and designer wears. A lot of efforts go into making them.”

Lights. Camera. Masala. is a hard bound book produced with varied process on varied material and with varied fabrication and gimmicks.

The audience was captivated while Aspi presented glimpses of a popcorn holder, a fan mail, the wheel of fortune, and a folded poster popping from between the pages. The books takes one back to the days when a film reel was used to make movies, with a printed image on the photographic film.

“These gimmicks,” Aspi said, “are not pasted but stitched between the pages. The inside pages has foiling. All these gimmicks, for execution eight years ago required a lot of hard work and engagement between the designer and the printer.”

While saying so, Aspi enlisted ‘the must-haves of producing a designer book’: A concept to start with; a print partner, who will discuss and give inputs before the design is finalised; product sampling that will evolve the design further; tonnes of patience; a budget to support your vision

Jak Printers won the Book Printer of the Year award for the fifth year in a row. Between Bombay and Mumbai, Dome over India, India’s 100 Best Destinations and Light and Shade in Life’s Glade were the four entries submitted by Jak Printers for PrintWeek India Awards 2013.

Spectrum Scan’s Anil Mathai discusses a gamut of POP/POS applications

“Where print ends, our job begins,” said Anil Mathai of Mumbai-based Spectrum Scan, during his presentation on the day two of the Print Fair for We the Production People.

Elaborating it further Mathai said, “When it comes to POP/POS, print becomes incidental. Producing POP item is a journey, which begins with a concept that needs to be developed based on the design to form a structure and shape. And then the artwork is pasted on that shape to produce the final POP item, which goes to the market.”

Spectrum Scan specialises in POP/POS items produced from substrates other than paper. For this the company employs screen printing, digital as well as offset technology at its Vasai factory.

Mathai stressed on the significance of screen printing. “Screen printing is argued to be an older and primitive technology. However, our world would collapse if we stopped using screen printing,” said Mathai. He validated his statement by sharing screen printing applications of printed circuit boards, control panels on machines etc.

Among POP applications, signages are done with screen printing. Mathai highlighted Spectrum’s award winning POP product, Cadbury Dairy Milk Silk signage which was screen printed and thermoformed. “The 3x8ft signage was produced by printing PET-G sheets on semi-automatic screen printing machines and then thermoformed to resemble a Cadbury chocolate bar,” added Mathai. “With screen printing various substrates such as polypropylene (PP), high impact polystyrene (HIPS), acrylonitrile butadiene styrene (ABS) can be used.

Speaking about digital printing, Mathai said that digital printing can be used to print on any rigid substrate such as leather, glass, marble, wood, tiles and flexible substrates such as flex, vinyls etc. “At the retail trade outlets, all the counter-top units and free-standing units (FSU), which require fewer numbers are produced digitally. Also, digital printing plays an important role in billboards and hoardings.”

According to Mathai, offset printing also supports a wide range of substrates such as LD foam, polyvinyl chloride (PVC), HIPS, PP, PET, PC, vinyl and all flexible substrates up to 1mm thickness. “One of the top offset jobs which attracted client’s recognition was Alpino’s table top. Wherever the quantity is larger, offset is the viable option for POPs.”

Mathai said, “When a user is at a modern trade outlet, he spends a lot of time standing in the long queues. Here, various cash counter POPs come in to picture to influence the last minute decisions of the buyer.” He showed samples of cash counter POPs produced for Nicotine, Cadbury, Colgate etc.

Speaking about the trends in POP segment, Mathai highlighted the concept of category hangers for sachets. These hangers provide brand visibility and product demarcation within the clutter of sachets at the retail store.

Mathai said, “Other engagement points include use of LEDs to attract consumers, larger than life structures, use of fibre-reinforced plastic (FRP) to make realistic products, thermoformed posters adding 3D effects etc.”

“Clients are looking for something different and innovation is the key. Spectrum is trying to contribute to it,” concluded Mathai.

Trigon’s Patricia Pinto reinstates the power of pre-press

“No press without pre-press,” said Patricia Pinto of Mumbai-based Trigon Digital as she initiated her presentation at the ongoing Print Fair at the Max Mueller Bhavan, Mumbai.

Elaborating her views, Pinto said, “If printing is considered to be a theatre then pre-press is synonymous to rehearsals.”

“As a poorly prepared actor will never wow the audience, similarly a poorly prepared print job will ruin the brand,” added Pinto.

Pinto stressed upon the gamut of equipment used in pre-press technology at Trigon. “The tools of trade used by Trigon Digital ranges from Kodak NX approval, Esko Konsberg for prototyping, pre- distortion software for shrink sleeves and 3D studio visualisation,” added Pinto.

“These tools are a time and money saver for a pre-press house. They can help one visualise the post-production processes before hand,” said Pinto.

“The 3D studio visualisation software has the ability to provide the customer with embossing, shine processes on the computer screen which helps the customers to cut down to single option instead of four or five mock-ups,” she added.

Pinto showcased the 3D visualised packages. “For every job, we give a timeline of 24 hours. We receive the artwork from the agency in four options and half the day goes in for the colour separation for the print. Later we make the 3D model of the pack using the 3D studio visualisation software in two hours and send it for approval. The final stage is the making of mock-ups from the approved artwork.”

“Time is money in the current scenario and to preserve time pre-press is an important stage before entering into printing,” concluded Patricia.

Top designers and production persons experience Silverpoint’s Augmented Reality

Augmented Reality was the show stealer at the second day of the ongoing Print Fair, where six print experts revealed the power of print on 7 November.

The audience of over 60 delegates was captivated by the experience of Augmented Reality (AR) presented by Silverpoint Press’ Saifee Makasarwala. The company has recently launched its AR brochure to showcase the pool of applications of AR.

Introducing the technology, Makasarwala defined AR as a camera enhanced view of physical real-world environment, where virtual elements are merged with real life scene creating a mixed reality of virtual elements and the real world.

Makasarwala said, “The virtual elements, given their nature, can consist of 3D models, video, web information and virtually anything. Your imagination is the only boundary with AR.”

At one instance a video pops up and takes you through a corporate video of the company, while on the next page a 3D structure of a building emerges; where you can view every nook and corner of the building from all angles. It also has mobile commerce embedded into it, which offers you to buy the product in the picture directly from your mobile device. “Possibilities with AR are endless,” explained Makasarwala. Makasarwala showcased the AR brochure, which has a QR code on its cover. It helps you to download the Silverpoint app from Google Play Store or Apple Store. “Once installed and run, the app takes charge of your phone’s camera and you need to view the brochure through the phone to experience AR,” added Makasarwala.

Silverpoint has created an AR brochure for its client, Bajaj Electricals, wherein the company’s director shares a video message and Bajaj’s award winning TV commercials are embedded into it.

Makasarwala informed that another client of Silverpoint, Rajguru Live, uses AR in interesting ways. “It allows the users to pose with a poster of Sonakshi Sinha and when a photograph is clicked through the app, it appears as if Sonakshi is standing besides the user,” said Makasarwala.

“The idea is to make print shake hands with digital and thereby make print more powerful,” concluded Makasarwala.

“Innovate or die is the mantra,” says Alpana Parida

On the first day of Print Fair, Alpana Parida of D Y Works stressed the necessity of innovation for the printing businesses to survive.

In her presentation ‘Printing Industry - The Next’, for more than 60 delegates in the audience, Parida showcased how it is important for any business to define itself. Citing the example of Kodak, Parida said, “When a business is defined in relation to the technology, they tend to fail as the technology matures and advances,” said Parida.

She shared an instance where a manufacturer of printed bags, when they found no value addition in the jobs being produced, started making security envelopes for banks. “Today, he is not just a printer but a security solution provider,” added Parida.

Parida highlighted the fact that there is very little integration between the three important aspects of a job namely substrates, design and printing. She said that there has to be a synergy between these three to bring about innovative concepts that would make the printed products more relevant in a world where print seems to be on a decline.

Parida observed few industry trends such as decline of personalised printing, move towards sustainability, down-gauging of packaging, functional packages, making packaging to work harder namely as point of sale etc.

“Change is the only constant; the sooner we learn and plan accordingly, it is better for our business,” concluded Parida.

“Printers and designers must collaborate”

At the Print Fair, which opened on 6 November, at Max Mueller Bhavan, Mumbai, one of the top Indian designers, Ashwini Deshpande’s presentation highlighted the changing dynamics of print industry.

Deshpande quoted Albert Einstein at the start of her presentation: “To raise new questions, new possibilities, to regard old problems from a new angle, require creative imagination and marks real advance in science.”

She stressed on the need for printers and designers to collaborate in order to generate ideas that can produce best jobs. She shared a project, which her firm Elephant Design undertook recently. “As per the brief, we had to make plastic packaging to resemble a paper-based product. We were able to accomplish it successfully thanks to the extensive support from one of our print vendors,” said Deshpande.

She said that important aspects of a printed product include design, brand, print and context; however one must not neglect the user, who is always at the centre of the picture.

She raised a pertinent question: Are we mixing skills and materials to make new? “For instance, a liquor carton, I came across, was designed by a fashion designer. It was a mix of jute, paperboard, decorated with embroidery, foiling and various finishing techniques,” said Deshpande.

“Also, glow-in-the-dark inks are not new to us. But how many of use it effectively?” asked Deshpande. She showcased a poster of a weathered tree. “The leaves of this tree are printed with glow-in-the-dark inks, which are invisible in presence of light. However, in the dark, it blossoms. It conveys a message of ‘Save Electricity, Save Nature’ effectively.”

Deshpande cited the instance of 3D printing, which according to her will sooner or later be a commercial and via ble technology in the country.

A student of NID, Ahmedabad, Deshpande is a print lover who misses the letterpress. “Print has always been fascinating for me since it affects people, culture and trade. If the art and skill of making Paithani saree has not become extinct, then why has letterpress died? I wish we bring back letterpress,” said Deshpande.

See All

See All