A printer needs to help customers realise that printers are superheroes

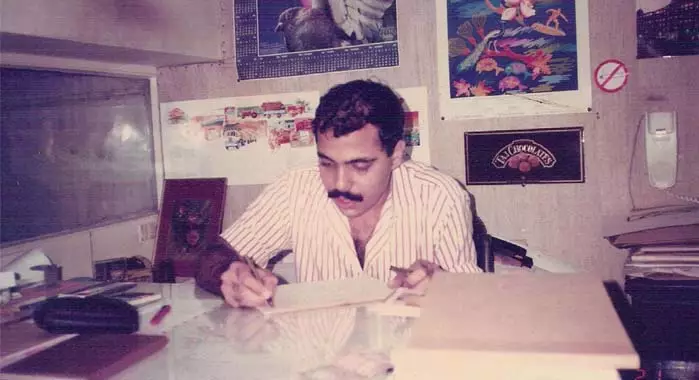

Khushru Patel, along with his childhood friend Aspi Forbes, started Jak Printers in Mumbai in 1984. Since then, its motto ‘quality never goes out of style’ and the slogan, ‘We make a difference’ have made them a top-quality printer in India, picking up NAEP Awards for nine consecutive times and for 12 consecutive years. Patel was in conversation with Ramu Ramanathan during the KMPA’s Print and Beyond seminar in Kochi.

21 Mar 2018 | By Ramu Ramanathan

Ramu Ramanathan (RR): What memories do you have of 1984?

Khushru Patel (KP): We had a folding table in a 300-sq/ft factory. When we would get more paper, we would fold the table and utilise the space for storage. Our beginning was small. It was a struggle. Initially, both of us thought of quitting the business and doing a job. After two years, we got a breakthrough from Taj. It was our first direct job for Taj.

RR: What do you think the Khushru Patel of 1984 would say about the Khushru Patel of 2018?

KP: I think I have done beyond my expectations and I am happy. Today, I am one of the leaders in print quality. The only thing is if I had been in the construction or jewellery line, the numbers would have been ten times our present numbers. Sometimes I think if I was a diamond merchant, I would be travelling in a private jet. Printing has kept me grounded. It’s a very tough industry.

RR: What are your memories of your Worli unit? You learnt a lot from your seniors, especially the Taj people.

KP: One of our friends introduced us to the Taj people. After the meeting, everything went well. We convinced them to do the job with Jak. The Taj guy was impressed and gave us a small job of Rs 3,500. In those days, Rs 3,500 meant a big job. The job was to produce 2,000 letterheads with advertising material on them. In those days, we used to do colour-proofs, progressive-proofs and take it to the customers. I showed it to them. It was 1986. I had done a FM Madoli and he was very impressed. It was Alabaster paper. Nowadays, pure Alabaster is hardly available. Later, I sent the delivery, feeling proud of my first direct job with Taj. Then he called me and said, please come over. I went to his office and he said, your job has been rejected. Look at your proof and what you have done. Quality of printing was fine. In those days, we used to hand-paste the positive. After the proof, in the final printing, one of the lines went outside his design grid by 3mm. At that time I understood the importance of design grid. He said, this has gone outside my design grid and I cannot accept it. I froze for a moment. I had two options, one to run away from the situation and tell him, sorry I can’t accept the rejection, but I was so scared that I told him, I’ll re-print. In those days, Rs 3,500 was a lot of money.

RR: You said there are always lessons to be learnt from a rap on the knuckles. What are these lessons?

KP: We were trying to survive. We reprinted the job. One was the fear, and this seemed the right thing to do. Plus, there was a high level of honesty. Since that day, we have not looked back. Sometimes, we need to make these decisions that we need to do our job and not run away from our customers. Plus, accepting mistakes is very important. There is no doubt that this has made what my company is today. We are a team of 150 people. Plus, there are additional three to four persons per family of the principal employees, who survive and thrive because of Jak. So, when I take a decision, I am taking it on the behalf of 500 people. Our strength is our willingness to accept: I can be wrong. And yes, I can make a mistake. But I must try and repair it. It’s very important.

RR: How do you handle failures now? I know you do apologise to customers.

KP: First of all, I’m a married man and I have two daughters; so accepting failures and apologising is the part and parcel of my life. Being ready to say sorry to two daughters and wife is very easy. So I am used to saying sorry.

RR: (laughs) Point taken. Is there the same level of honesty and integrity as earlier?

KP: We have to accept our failures happily. But we want to get it right the first time. Our motto is to get it right the first time. And most of the times we do get it right. But 10% of the times, we fail.

RR: What do you with the 10% failures?

KP: Like I said, failures are important. But we need to accept them stoically. Then we need to take a step back and dissect the failure and analyse what went wrong and ensure that we don’t repeat it.

RR: You mentioned that your first motto is to get it right the first time. What’s your second motto?

KP: Our second motto is quick response time. This is very important in this day and age. If I cannot give you a quote, I can say, I’ll get back to you tomorrow. This is a response. Even if you don’t have an answer today and you can only provide an answer tomorrow, I think you need to call your customer and say, I’ll get back to you tomorrow.

RR: Back to Jak, what happened next?

KP: We started like most print firm owners. I’m sure most of us have started in small premises. We have all heard Bhuvnesh Seth of Replika share how they began at Mandi Bazar and named the company Rajkamal Electric Press. Do you know why it was called Rajkamal Electric Press?

RR: No.

KP: In those days, presses did not run on electricity. The machines were pumped by legs like sewing machines. In that era, Bhuvnesh Seth’s father acquired a press with an electric motor and that’s why they called it the electric press. It was a big thing. The point is printing has evolved.

RR: How did you make the transition from the 375-sq/ft gala?

KP: From there, we shifted to another premises in Worli, which was around 500 sq/ft. Then came Dr Manmohan Singh, the finance minister, in the nineties and he opened up the industry and the country’s economy. He said everything is going to multiply. And so, in that excitement, we planned to shift our plant to New Bombay. That’s how we built up a factory space of 20,000 sq/ft. We were slow. And by the time we were ready, we realised the economy has grown but the print quantities had not grown.

RR: So, what did you do?

KP: It was an interesting phase. Let me explain with an analogy of a car. Earlier, we had Fiat Padmini. We thought if consumers had earlier ordered ten thousand cars, now they will ask for hundred thousand cars. Instead what we found was that 20 more cars were launched. So the car orders were restricted to two thousand bookings. And so, even though the economy grew, and the demand for cars grew, the quantity per car shrunk. So we thought running an industry from outside Mumbai was not prudent. The New Mumbai premise was at one hour distance from where we were staying. Plus, we felt that it was something we couldn’t control. So we sold it off. And that’s how we decided to be in the heart of Mumbai.

RR: Huge losses?

KP: Some big losses. But we took care of ourselves. Our friends, even the machine handlers and the agents kept laughing that we had not done anything new since so many years and we were history. But we acquired this place in the heart of Bombay. It’s a one-acre property which we own and we use 31,000 sq/ft.

RR: Your plant is beautiful. I mean it’s not just a printing factory; it’s a labour of love. This combination of the beauty and the beast, how do you manage it?

KP: First question, who is the beast here? Do you mean me?

RR: (laughs) No, no. The machine is the beast. The entire factory is green, plus the work environment is fabulous.

KP: First of all, I am quite clear. We want to live comfortably. But it’s not only about making money. My brother and I, we think differently. I feel you have to be happy and you have to be comfortable. And if you are not happy and you are not comfortable, you will not be able to produce good jobs. The same principle applies to the staff. If your staff is not happy, and they are not comfortable, they will not be able to produce a good job. We have to make our staff happy first for him to make you happy. In return, you can make your customer happy. Which is why, our aim is to make the environment cheerful and healthy.

RR: Your plant is very green.

KP: We have a well in our premise which was shut by the previous owner. We reopened it. Even the greenery that you see extends to the main road. We have taken permissions from the BMC to plant trees. We water them and maintain them. We use all the water from the well. So we try and conserve water.

RR: What does your staff feel about it?

KP: When we shifted from the industrial premises to this place for approximately two or three months, we had a real tough time. The staff felt they were on a vacation and they were not able to focus on work. It’s good to feel you are in a hill station and you are very happy about it. However one needs to work too.

RR: The next big change came when you installed a Heidelberg with an autoplate system. Tell us about the technology shift?

KP: This was in 2002. Back then, autoplate was very new to our country, at least in Maharashtra and Mumbai. I recall the city had two or three presses. Jak got a six-colour press. It was a very young machine along with autoplate and autowash. We paid a premium in those days.

RR: How?

KP: Please understand that the Mumbai market is different, starting with the real estate, which is so expensive. To actually invest in real estate and then invest in printing equipment is hard. The cost becomes prohibitive. Anyway, we got this machine. In the industry, a lot of my friends challenged me. They warned that I’ll shut down. That shook me up. They felt that I had invested more than I could afford. But we had a plan and the plan worked.

RR: What was the plan?

KP: Our idea at that time was if you get a job of 48 sets, you will need one-hour makeready time on a non-autoplate machine. Plus, you will need one hour to print 2,000 quantities. Calculate it: 48x2. This means 96 hours. On the other hand, with autoplate, you can finish the print within half the time. And so, by the time my competitor finished printing half the books, I would have delivered 100 copies to my customers. We worked on this and we succeeded. It changed the way our customers thought about print. We circumvented the delivery delays. It was a huge step in that direction. Otherwise, I don’t know where Jak would have been.

RR: Post-press has been an area where some people say Jak over-invested. For example, the Kolbus you have. Did the investment justify the volume Jak produces?

KP: You are right. The kind of investment we have in our post-press division is not justified. A lot of people ask me about ROIs and I am baffled. Honestly, how can you calculate ROI against quality? At Jak, we have never done that and we have succeeded. Listen, we are not in big figures. We are not churning out numbers and shaking up the volume market. But we have succeeded.

RR: How so?

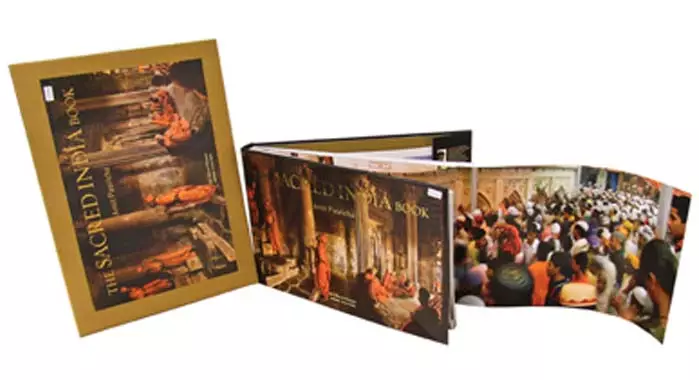

KP: I’ll take you back a little bit. We started making hardcase books. Once we got this machine, we started doing lot of books and that’s where we succeeded. I took one of my best books to Germany and I had that opportunity to go and meet Mr Siegloch of Siegloch. You know, I have never asked a film actor or celebrity for a picture with me. However, with Mr Siegloch, I requested for a picture with me. He is a book binder’s Amitabh Bachchan.

RR: Wow!

KP: Yes, wow. When I showed him my book, the book that I had created, I thought he will be wowed! And he’ll shower me with compliments. Instead he kept inspecting one page after the other — the hard case, the end paper, the spine. Basically, he decimated me by showing me all my mistakes. I was stripped down to my skeletal remains. He showed me mistakes which I had never understood, plus defects and errors which I had never thought of. It was very humbling. After this, he showed me around his plant. He explained to me why they were doing certain things and how they were doing it. That day altered my life. Once I returned to my desk in Byculla, I was determined to put in a complete bindery. Without which, I felt I would be doing injustice to my customers.

RR: How do you invest in a machine?

KP: Luckily, both my brother and I are technically qualified. We ensure that we learn about each and every machine that is on our premises. We educate ourselves. Also we run the machine and then buy the machine. This is one of the mantras of our company. We picked up the Kolbus line from Australia. My brother stayed there for 15 days and worked on it and only then did we get it here.

RR: On cue, you started competing with firms in Singapore…

KP: Oh yes. The books we created were good. I challenged many of my customers when they wanted to negotiate rates with me. I told them if you don’t do it with me you will have to go to Singapore. That’s the level of quality we want to give and we do give. Which is why, we demand that respect in the industry. And we get it.

RR: What is the structure you follow on the shopfloor?

KP: We have eleven teams for our boutique press. We have 82 machines, out of which four are printing and the remaining 78 are for post-printing. We have invested heavily in that department but we are happy. Individually, the machines may not be delivering their full capacity, but as a company we have grown. Even when we put the six-colour autoplate press from Heidelberg, within three years, we started earning profits in the range of our earlier turnover. That’s why I feel, one needs to take risks. But those risks need a plan. Then you need to work hard to execute those plans. A printer always works hard, twice as much compared to other industries.

RR: The ticket size of a job has drastically reduced. The reason I am asking this question is because a lot of printers (SME or MSME) want to know how to cope with the pressure of a shrinking job size?

KP: Let me rewind a bit. Jak is situated in the heart of Mumbai city. We have a small showroom where we show our products. So mostly we invite customers to our place. That’s the first point. If you have not invested in it, please make a small area where you can keep all your print products about which you feel proud. You can’t carry everything to your customer. So make sure you call the customer to your premises. Ensure the room is comfortable and classy. Each and every product must be demonstrated properly. This is the time the customer understands what you are capable of. When I see a customer walking out of Jak positively, I know I have succeeded in making him think differently about print. If he is convinced that he is at the right place and getting the best product, then cost is never an issue.

RR: What is the reason top photographers, top painters, publishers in India trust you?

KP: I totally confuse them. They don’t know what the hell we are doing.

RR: (laughs) Surely, there is more to it…

KP: Apart from confusing the customer, we start reading about what they want. A customer may be looking at the reproduction that his daughter has painted or the silver lining around the lamps and so he is seeking a metallic silver in the final job or a menu card that can be read in the dark. It’s like a doctor who diagnoses and then prescribes. A printer is like a doctor. Try to understand what the customer’s pain point is. Is it colour? Or finishing? Or packing? The printer needs to be a doctor. The printer needs to hypnotise them and dazzle them. A printer needs to help the customer realise that printers are superheroes.

RR: One job at Jak, if I’m not mistaken, had three shades of black and two shades of grey and I recall talking to Aspi who said that the job was reworked multiple times until the customer was satisfied. Do you recall this?

KP: Basically, this customer came to me. She wanted a black and white book. I said this is not black and white and she was like I’m a photographer I have done six books in my life and you are telling me this is not black and white. I said, relax. Get me four images to prove my point. We took the images and we processed those tones with black and grey and then we showed her the proof. Now, as you know, every four-colour black has a blue or a red or yellow, it will never be 100% black. Anyway, we showed the final proof to this lady. And as has been the case with customers, the lady never asked for a quote after that.

RR: Jak has invented paper engineering. What does it entail? How has it benefited you?

KP: We are careful about paper. Even today, how many printers understand grain direction? At Jak, we make extra efforts to understand paper. When we were into paper engineering, we were doing pop-ups. We produced boxes. Then we did pop-up books and pop-up cards. In all this, paper engineering means to understand the capability of each paper, what can it do or can’t do. The way every human being is different or every car is different, every paper is different. Study the paper. Understand the process that suits the paper. How do you make a good product? Do trials with the paper.

RR: How many trials?

KP: Do a zillion trials. A small rejection will not shut your press down if you are aiming for quality. Big rejections are not allowed if you are trying to do something new. Anything new is going to have problems, especially if you are trying it for the first time. If there is a book job with a print run of 10,000 or 1,00,000, which is very big for us, we start with short runs. We understand the job, repair the mistakes. And only then do we produce the full batch. It’s very important to remember that small rejections and trials are not going to shut you down.

RR: How do you track paper? Do you visit Paperex or Paperworld or do the suppliers and vendors or customers discuss paper ideas with you?

KP: No, we don’t go to paper trade shows. It is the suppliers who come with the paper. We have a team of 11 which does client servicing. We don’t have sales team but we have a client servicing team because it’s more important to service your client. Since every client has that one unique demand, it’s important. When the client servicing understands what button works for the client, everything clicks. Whenever a new product comes into the market, the suppliers come to us. We give them a specific time. Normally its Tuesday 2.30 pm. The eleven of us sit together. The supplier shows us his bag of paper. We do the brainstorming. We get inputs from production people as well. We do trials and somewhere down the line, if the paper works, then it’s great. Sometimes the paper gets lost in the whole system.

RR: Does this system always work for you?

KP: Of course, we have our faults and our strong points. That’s the way we work and we do make mistakes. We are not gods. I think even gods make mistakes but we should learn from our mistakes and tweak the system and better our common sense.

RR: But you always include the team in decision-making?

KP: Yes. The team is the key. And this is not a mere lip service. I have been to so many award ceremonies and it’s sad to see that only the owner comes and receives the award. I feel that the award is not owned by the owner. I think the award is owned by the team. Therefore, it is the whole team. We never see the entire team on the stage. Even if it’s not the whole team because you can’t afford to fly down 15 people plus hotel bookings, at least ensure two people or four people are part of the award night. It’s very important to do so. Remember, it is not about you standing up on the stage and feeling proud so that you can show that picture to your mother-in-law. You make your team answerable when a job goes wrong, and you fire them. So you remember them only when there is a bad job. But they need to experience the high of an award winning job too. They need to be happy.

RR: So, you request all print CEOs to take their staff the next time they are going to receive an award?

KP: I took one of my team members in a flight. It was his first time flying. While returning to Mumbai, he had an aisle seat. I told him to sit near the window, since he would enjoy the view when we landed in Mumbai. He saw Mumbai city from above in the night time, and he was so happy. Now, if I tell that staff member to create the same sort of magic he saw from the 30,000 feet above the ground, he understands what I am saying. He will do that for me. My point is, you need to develop your team; it’s very important. Print is not a one man show.

RR: You are a gastronomic expert. The famous Parsi Dairy Farm in Mumbai is part of your family. Once when you invited me for a home-cooked dhansak lunch at Jak, you said to me that selecting ingredients for printing is similar to selecting items in your recipe. You added, if you use better product, the results are better. Please explain how you sustain this? Who pays for the expensive inks and the expensive raw materials?

KP: Look everybody, I’m going to show you a bit of magic. (Patel does a bit of abracadabra, but nothing happens). So, could you see it? No? (The audience says, no.) The point is I’m not a magician. Remember: quality is not something done by magic. Quality will happen only by selecting the right products at the right price and producing them on the right equipment and having the skill set to develop a good product. It’s very important that you asked this question. How does Jak afford these raw materials? The answer is simple. We earn less. There are printers who have started out with us, who own the latest Mercedes-Benz or BMW. We are happy and comfortable. My staff is very happy.

RR: Horse riding?

KP: This photograph has been shown here for a purpose. It’s not to prove that I can do horse riding. The fundamental question is, are we happy? Why are we working? To enjoy our work. So don’t punish yourself. Don’t punish your staff. If you have a passion or a dream, chase it. For four and a half days, I do printing. And for two and half days, I do horse riding. I have a small farm in the hills. I teach children over there. I have taught kids horse riding. These kids have won the nationals. This gives me a lot of satisfaction.

See All

See All