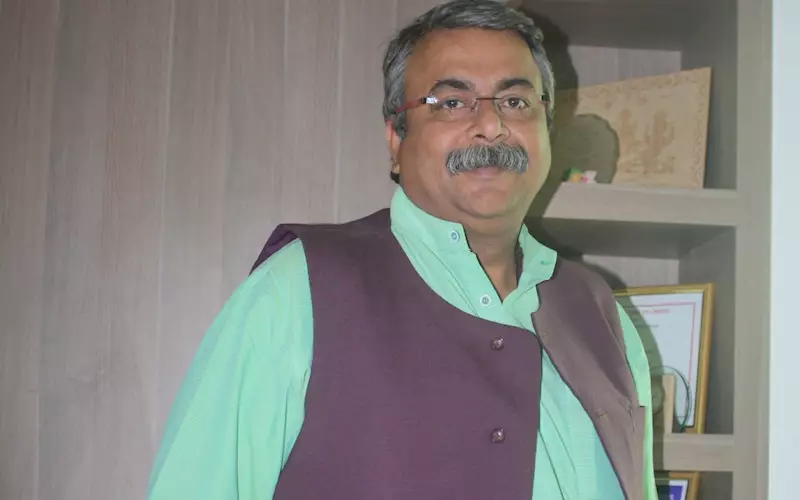

Thought process of printers is changing in Rajasthan: YK Narula

YK Narula is not only the president of Rajasthan Printers’ Association; but also the managing director of Printers’ Emporium, which deals in several print and allied machinery and consumables. His father too was a printer and thus his veins have more ink than blood. He spoke to Supreeth Sudhakaran about the major trends of the Rajasthan, and why diversifying into packaging is a “wishful thinking”

04 Feb 2014 | By Supreeth Sudhakaran

What are the major trends in Rajasthan’s print market?

Thought process of printers is changing. Not only commercial printers but newspaper publishers too are embracing newer technology. They have understood its advantage and importance of adopting these technologies. The market has always been split between two competing technologies. Earlier, the competition was between letter press and offset. However, now the competition is between brand new offset press owners versus refurbished offset press owners. The first wave of change came when single colour offset presses were replaced with four colour offset presses. The second phase began when these four colour presses were replaced by four or more colour presses but with updated technology. Print business owners are now adopting a more professional approach to their businesses. Printers have started setting up designing and pre-press departments with their shopfloor; this was a rare sight few years back.

How has been the growth of CTP and plate consumption during these last five years?

CTP installations and consumption of plates has tripled in last five years. The commercial printers in last 2.5 years, at least 16 establishments have adopted CTP technology. It’s not just leading newspapers publishers such as Rajasthan Patrika and Dainik Bhaskar who are adopting CTPs and CTCPs, tier-2 newspaper such as Dainik Navjyoti and many others too are installing CTP devices. Dainik Bhaskar alone has installed 60 CTPs in last three years from Technova. Rajasthan Patrika moved from conventional plate processors to CTPs. Even those who could not afford to graduate to CTPs have at least migrated to MetiJet systems. Willingness to change and upgrade is now visible, which is an encouraging sign.

Across India, many commercial printers are currently contemplating in diversifying to packaging. Is there a similar trend in Rajasthan?

Rajasthan is a poor state in terms of industry. Major business is around jewellery, textile, real estate etc. There aren’t many manufacturing units in Rajasthan. Therefore, entering the packaging domain is always a wishful thinking, according to me. There are few players, who are working on building their business in the packaging segment by focusing on print buyers from outside Rajasthan market. However, commercial print market still holds potential. Wedding business, publishing industry, and real estate are supporting this growth in commercial. Only a small fraction of the printers in Rajasthan are building their business solely dependent on packaging, others are offering a mix of commercial and package printing. Printers have to create a differentiation to survive in current market scenario.

You have been distributor for Technova. What are new developments on the part of Technova?

In last couple of years, Technova has been transition from being a manufacturing company to training of variety of products related to printing industry. The first phase came as CTP selling, then they added consumables coating, blankets, and gradually they are increasing their base in terms of providing the materials.

In terms of understanding a company marketing strategy and their survival in the market, one major part they realised is that if they want to survive and remain leader in the market, then they need to cater to the complete requirement of a printer. This aim cannot be achieved by just focusing on plate or plate making device. There are several of other things which the printers demand.

From a trading point of view, I feel this should be model for all the traders also. They should be positioned to give a complete solution to each printer of their territory. Second, Technova’s entry into service segment be it consumables, technology, is an excellent way of indirect marketing. This was earlier seen in other industries like marketing sector, but increasingly becoming the norm in the manufacturing segment. Companies are in constant touch with customers; right from the start of the product planning to the end phase of packaging. Technova has mastered this.

Last couple of years are being called as the year of consolidation and M&A. Is Rajasthan print industry too been affected by this?

The trend is coming up faster than expected. In spite of being in the business for such a long time, even we thought about consolidating the business. It is not just the financial factor that makes the difference; it is also the periphery in which you function. The economic situation of the country and your own personal and mental health also govern the decision to whether consolidate or merge with another company. Although, printer in Rajasthan are not yet thinking about selling their stakes in the company, they are definitely planning to enter in overt and covert arrangements with each other and work together.

See All

See All