Shree Printwell Offset, Surya Offset, Mail Order Solutions and Vyoma Graphics, to name a few, have one thing in common. All have complemented their offset print operations with digital print. They understand that offset printing has been and will remain the workhorse, but there are areas in which digital printing can become more profitable.This Sunday Column takes a look at how the interplay can translate into better print business

One of the things that we are seeing happening, even in India, is that printers with offset as its core operations are now adding digital to their armoury. So much so that manufacturers of offset presses too, are making it clear that its focus on future developments will be on a combined technology of offset and digital.

Heidelberg is working with Fujifilm and is set to launch B1 inkjet presses while HP in conjunction with KBA has launched the PageWide Web Press T1100S, among other manufacturers.

What the combination of technology does is allows the offset printers facing lead time issues as well as initial setup cost to get into new markets and increase their bouquet of offering, particularly in areas like photo books, or adding value to products with variable data for unique identification, direct mail or web-to-print solutions.

How does one run both the technologies? Should the two operations, offset and digital, run separately? Should they be using different workflows?

During Drupa 2012, Heidelberg and its partner Ricoh used the HEI Flexibility platform to demonstrate the Heidelberg workflow with a common colour management producing a package that was printed using offset and digital printing, and both, it was claimed, were close to each other in the quality of print.

The digital fit in offset

In the consumer segment, products are being launched on a regular basis, life spans are becoming shorter, which means new products are being launched or repackaged and re-launched. Accordingly, print promotional items, which were being printed in bulk, stored and distributed, are now printed to requirement. This has brought short-run into focus. With offset, one can play with volumes, but when doing short runs, it can be challenging. Digital print gives you an option of choosing what you want to print, based on volumes, and that’s a phenomenal edge.

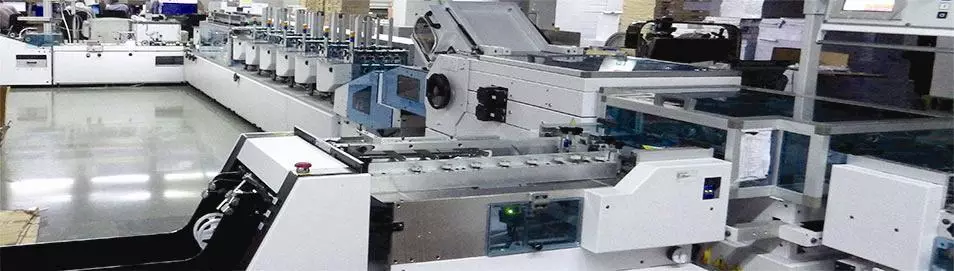

Among those printers in India, who have brought in digital printing to provide a complete service to its customers, is Mumbai’s Mail Order Solutions (MOS). The company is a print project specialist with a focus to provide a wholesome one-stop solution to clients across varied industry verticals like insurance, mutual funds, banks and direct marketers.

Among the digital presses, MOS has Ricoh Infoprint 5000 and 8100s digital presses to complement the two Heidelberg SM 74 four-colour presses. “When we first invested in digital, it had become a necessity, because we had to transfer few short run jobs from offset to a technology that would make it more profitable for us. It also had to match offset printing quality and colour reproduction,” says Mehul Desai, the chairman and founder of MOS.

Desai adds, “The investment in Ricoh Infoprint 5000 also was necessary since volumes were going up, clients were asking for more stringent turnaround times, and flexibility was needed.”

Pune’s Vyoma is another example of an offset operation getting into digital. During one of our visits to Pune, I met Niten Shah of Vyoma. We were surprised to see a digital press installed at the plant.

Why a digital press, we asked, and he replied: "why not?".

He continued: "For a print provider, the questions are: will the equipment do anything more than the current equipment does? Will it help me grow my business?" Well, the answer is "yes". Vyoma can produce short-run, highly targeted printed products, for which digital presses are better suited.

But Shah also says that if these jobs can be cost-effectively produced on an offset press, "I will print on an offset.”

Consumer operations business

While MOS has covered itself in glory with variable data printing for one-to- one marketing and direct mail, Ahmedabad’s Shree Printwell Offset too made a success out of venturing into consumer operations such as the photo book segment.

The 24-year-old company, invested Rs 5-crore in commercial printing in 2010, including an investment in HP Indigo 3500. Shree Printwell embarked on a journey of digital innovations with the deployment of Taopix's photobook platform (the company does not use Taopix now). Clubbed with a six-colour HP Indigo 3500 press, in-house operations from pre-press to post-press, Shree Printwell produced personalised calendars, yearbooks, greetings cards, diaries, posters and albums.

Today the company works on employee model for the photo business under the brand Photo Orange and is open to a pan-India network of photographers with exciting offers. All this, when the wedding industry in India is pegged at Rs 35,000-crore and trends like pre-wedding shoot and theme weddings have just begun to gain popularity.

Printwell Offset's managing director Pravin Patel, says, "Digital production technology in the photo album segment has fundamentally helped us increase our customer base by leveraging the business to business (B2B) market of the professional photographers in Gujarat and other parts of India.”

Dwipal Patel, the marketing director at Photo Orange, says, “We see an increased demand for premium photo products. In the last couple of years, we have witnessed rapid developments in our digital printing business. Our digital volumes are up 20% vis-a-vis our commercial and packaging print business. I strongly feel that this is the beginning, and there is a lot more to come in the digital space, which we hopefully will see at Drupa 2016.”

Levels of investment

Sheetfed digital printing has made strident improvements over the last few years. While the HP, Kodak and Xerox have continued to build bigger and faster machines, the mid-segment and entry-level devices have also seen key developments.

Among others, offset print specialists, Silverpoint Press and Parksons Graphics have invested in HP Indigo presses.

Silverpoint saw momentum behind its short-run work and proofing following the HP Indigo 3550 installation while Parksons spent in an HP Indigo 5600 to cater to the on-demand short-run book business.

"We are excited to offer our customers true lithographic quality printing on virtually any substrate, and the lower environmental impact the press offers is just as important as the quality," says Saifee Makasarwala, COO, Silverpoint.

Animesh Kejriwal, director at Parksons Graphics, who got its first digital production press, says, “The digital side of the company has growing rapidly. We are witnessing increase in the requirement of on demand book printing. To cater to short run jobs like brochures, catalogue with special effect we felt that Indigo 5600 is the best option.”

While Xerox, Konica Minolta have upped the capabilities of its mid- and entry-level presses, Ricoh introduced the Pro C9100 and 7100x with a fifth station for white or clear toner.

The C9100, which was launched in September, 2015, gives Ricoh an industrial volume space, which can deliver a monthly volume of one million A4 pages, as well as high print speed of 110ppm and 130ppm. The machine prints at a print resolution of 1,200x4,800dpi and accepts a wide media range from 52-400gsm.

Umang Singhal, national business and marketing manager, production printing Singhal at Ricoh, says, “These type of volumes and speeds, are occupied by the likes of HP Indigo, NexPress and iGen presses. With the C9100 Series, Ricoh offers an affordable kit with similar productivity, greater media handling capabilities and print quality.”

Other new features of the C9100 include air-assisted duplex banner printing, up to 700mm in length, from a bypass feed unit, which are roller-less.

Since its launch late last year, the Ricoh Pro C7100x has seen a good number of installations. Singhal said, “The new digital printing press with a fifth station for white or clear toner is a winner for Ricoh.” There are around 35 C7100x installed across India.

Surya Offset - mid-volume kit investment

One need not invest in high-end machines; even mid-level digital production press can meet some of the requirements.

Surya Offset, the Ahmedabad-based commercial and security print specialist, has three printing plants operating. One is at Amli (Bhopalgaon), which was started in 1987, another at Changodhar which was set up in 2006, and the recently acquired plant in Sanand. However, to meet the short-run requirements, it invested in two digital production presses.

But when the company acquired a business for delivering a special features travel document, it was looking for a digital printing press, which could address the challenges of printing on media types – special texture media, duplex printing. “There were challenges we had to meet. We perhaps could not do it on an offset press. And beyond this, the company also had to keep the investment within its budget,” said Kashyap Purohit, a director at Surya Offset. The company turned to a mid-range kit.

Kashyap Purohit of Surya Offset

Purohit says, speed at times does not matter. “In a competitive capital intensive market, this low investment kit provides quality similar to high-end digital presses. And for the type of work we are undertaking, the speed of 60ppm is just perfect.”

Dwipal Patel, the marketing director at Photo Orange, says, “We see an increased demand for premium photo products. In the last couple of years, we have witnessed rapid developments in our digital printing business. Our digital volumes are up 20% vis-a-vis our commercial and packaging print business. I strongly feel that this is the beginning, and there is a lot more to come in the digital space, which we hopefully will see at Drupa 2016.”

Dwipal Patel, the marketing director at Photo Orange, says, “We see an increased demand for premium photo products. In the last couple of years, we have witnessed rapid developments in our digital printing business. Our digital volumes are up 20% vis-a-vis our commercial and packaging print business. I strongly feel that this is the beginning, and there is a lot more to come in the digital space, which we hopefully will see at Drupa 2016.”

See All

See All