Shuban Prints produces cartons efficiently with Bobst

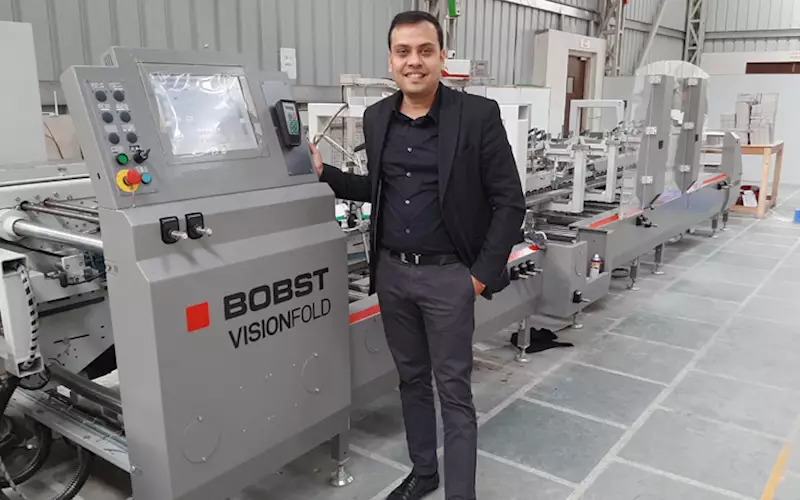

Bharat Gupta of Jaipur-based Shuban Prints tells Rahul Kumar how its Bobst Novacut 106E with stripping die-cutter and Bobst Visionfold 110 A2 folder gluer helped produce cartons more efficiently with cost-effectiveness, less wastage and less manpower.

28 Dec 2020 | By Rahul Kumar

A young and dynamic entrepreneur Bharat Gupta, who had been using four manual die-cutters and an India-made folder-gluer to complete print production, especially post-press at Shuban Prints, was looking for automatic equipment to make print production efficient and faster.

“We have a complete setup, from receiving/ generating artworks to delivering the final product,” explains Gupta. “As business grew, we felt that post-press is the segment where we were lacking of equipment and technology because of slow speed and manual intervention, quality of the cartons were not up to the mark, especially when we needed faster conversion.”

Thus the search begun for a die-cutter and a folder-gluer which can help the company produce folding cartons and flute cartons faster with less or no manual intervention.

“Quality of the cartons was the key. So, we zeroed in on Bobst in 2018 and the next year, during Printpack 2019, the deal was inked,” says Gupta.

Shuban Prints bought a Bobst Novacut 106E with stripping die-cutter with top speed of 8,000-sheets/hr and a Bobst Visionfold 110 A2 with corrugation kit attachment folder gluer. The folder-gluer was installed in March and the die-cutter was installed in May 2019.

Explaining why the company went for Bobst, Gupta says, “We produce mono cartons and E-flute cartons. We were struggling with our existing India-made folder-gluer as it was not able to cater to corrugated cartons. Even mono cartons were also not moving well on the belt. E-flute jobs too were the tough for us.”

Now, after the installation of the Bobst equipment, Shuban has successfully overcame the earlier limitations.

“The Bobst’s folder-gluer is stable and folds and glues the sheets with perfection and efficiently,” Gupta says. “Cartons run on the belt smoothly. We ran the folder-gluer for one specific carton at the speed of 50,000 cartons an hour, especially for side pasting whereas with our Indian folder-gluer we were able to convert only 10,000 cartons an hour. Thus, we can fold and glue cartons five times faster. Quicker conversion made us more cost-competitive in the market.”

Shuban was the first in the country to get the 3.0 version of the die-cutter, Bobst Novacut 1060. It is equipped with push setting for die-cutting plates; corrugation and duplex can be on single side lay; pressure setting is automatic, which reduces makeready time; and clamping of dies is hydraulic/ automatic.

“We are running at average speed of 7,000 sheets an hour of duplex on our Novacut,” Gupta adds.

Shuban also has a pre-owned die-punching machine SPI260. So Gupta says, the company was familiar with the quality and use of the equipment. “In this machine, we have to change the entire part compared to the new one. We still have manual die-cutters and we use those for our customers from the confectionery industry. Die cost is major in manual die-cutting and manual intervention is also on the higher side,” he adds.

Gupta says with Novacut, rejection of jobs is almost zero; piles are very well created and very less manpower is involved. “We found Bobst post-press equipment to be most stable and trusty machines in the market,” he explains. “There are economical options available in the market, but there is a big question mark on their performances, especially in the long run. Thus, consistency becomes an issue with cheap options.”

Gupta is so happy with the investment that he says for future expansion, the company will opt for Bobst only. “We are working to opt for collection/ stacking tables from Bobst,” he adds. “It being capital equipment, ROI may be a concern, but believe me it is easy and faster because conversion is much faster, less manual involvement and decent saving on wastage.”

With Bobst, Gupta says the company’s customers’ portfolio has increased up to 35%. “Technology and brand of the machine really matter when you approach print buyers. Our customers show confidence on Bobst compared to other brands,” he says. “With Bobst, manual intervention in the jobs is very minimal and we could reduce our wastage from 3-5% to 0.9-1.2%. Bobst provided onsite training to our staff for smooth functioning of the machine and to make our staff skilled.”

See All

See All