Skanem: Raising its label profile in India to make an impression

Skanem acquired Interlabels in 2012 to gain entry into the Indian label market. After a two-step acquisition process, Skanem India is now producing labels that catch the eye, and add value to its customers' products. Skanem is poised to leap to the next level, Vinod Vazhapulli, managing director at Skanem India, tells Noel D'Cunha

05 Nov 2019 | By WhatPackaging? Team

Noel D'Cunha (ND): Tell me about your journey in this industry so far.

Vinod Vazhapulli (VV): I started my career with PRICOL (Premier Instruments & Controls). After that, for around 12 years, I was with ACG (Associated Capsules Group). During my 12-odd years with ACG, I grew from being a sales engineer to a business / P&L head. At 34, I was one of the youngest P&L head in the whole Group. Then I joined Skanem India for one year, as vice president and business head for the machines business unit. Then I moved on to ICC (The Indian Card Clothing company) as their CEO for two years.

And in January 2019, I re-joined Skanem India as managing director.

So basically I have moved across many industries - automotive ancillary, pharma and pharma engineering, packaging, and textile engineering, during the last two decades of my professional journey.

ND: Skanem acquired the label business – Interlabels – to gain a foothold in the Indian label market. How has the acquisition changed your business growth?

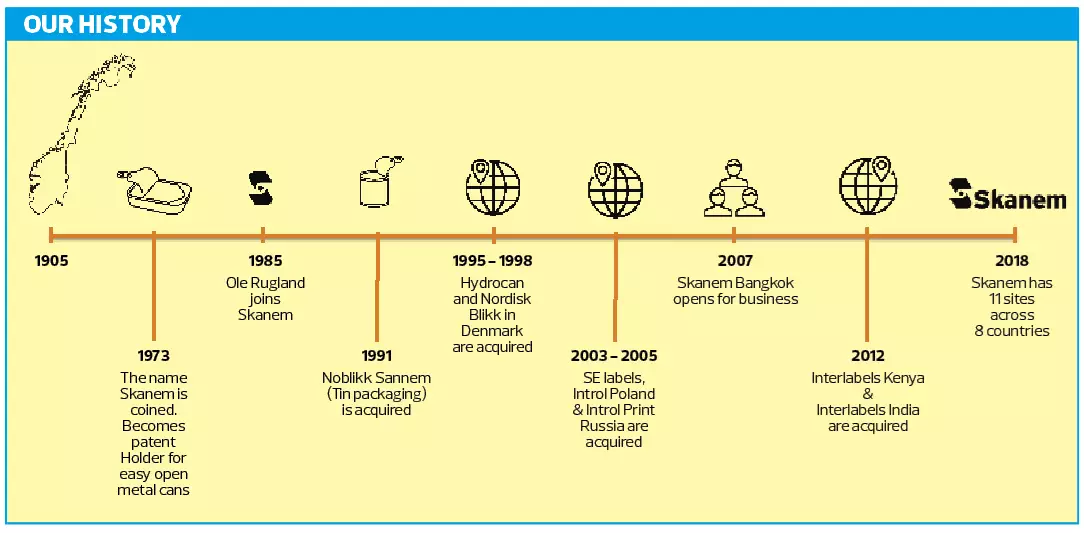

VV: As you rightly mentioned, Skanem wanted to increase its foothold in Asia and Africa, and that's the reason they selected Interlabels.

ND: Was there a process that was followed?

VV: The takeover happened in a two-step process that was agreed upon from the beginning: the first step with partial ownership in 2012 and the second step with full ownership two years later. During the following period between 2014 and 2017, the critical decisions of the government created some challenges – the first thing was demonetisation, the second was the rollout of GST, which impacted the business.

Now, in 2019, we are at a stage where we have found our footing in the market, and we plan to leap to the next level. Having said this, we aim to grow at a CAGR of close to 15% on a year-on-year basis.

ND: Generally, acquisitions are not always smooth. Is the culture gelling well?

VV: There's a term in management called cross-cultural sensitivity. India is a world by itself. We have our own culture, which makes us unique.

We need to translate and explain some local aspects, but the Skanem values are also applicable in India.

ND: What are they?

VV: These are continuous improvement, trust and team spirit. I keep them in mind on a daily basis and live up to them by taking care of employees, putting systems in place, investing in training, and being transparent. I love what Richard Branson said: "If you take care of your employees, they take care of the business."

ND: How do you do that?

VV: Just to give you an example, we started the culture of 'Quarterly Town Halls', wherein we discuss our quarterly results, areas where we did well and where we need improvements, rewards and recognition in terms of "employee of the quarter", celebrating birthdays, etc. Every month, after the result is published, I meet up with the entire team across all our three sites at Mumbai, Baddi and Guwahati as a part of our 'Mini Town Halls' where we have a half-an-hour interaction covering the same topics as the

Quarterly Town Hall albeit in a very concise manner. We also discuss how the forthcoming months look like for us.

Apart from that, every week I have an interaction at the shopfloor level. So, there is transparency with regard to where the company is, what is the growth path of the company, and what are the areas of development. Even a person on the shopfloor will tell you that. That's the level of transparency that we have maintained – from top to bottom, because an inspired employee is the best asset for an organisation. Take care of employees and encourage them to give their best. Once you have that, you don't have to go and take care of the nuances. Empower, delegate, and then leave them.

ND: You said you inspire the employees. But isn't there some sort of pressure on them when you set targets?

VV: No. I'll explain it. There's a difference between passion and pressure. It's probably the two sides of a coin. For example, if you tell a renowned batsman to go and manage a company, probably it would be putting pressure on that individual. But tell the same individual that you've got five days, the whole pitch is yours, go and bat as long as you want; that's passion for that person.

So, when you do something out of passion, it's no more a pressure. Pressure is when you don't know what you're doing. So, you must be transparent. Tell them what you expect from them, how it will benefit them, the organisation, and their family. It becomes a passion when everybody knows what is expected out of them. That is the way that we treat passion and pressure.

ND: I saw a lot of systems in place except for your pre-press area. When it comes to label, the data from pre-press to proof to finally printed labels, need to be managed. Shouldn’t this be automated?

VV: We have already invested in an automation engine for pre-press. It's all about the priority of investments right now. First, make sure that the people are aligned, invest in the priority areas, train the people, put the systems in place, and make sure the data is available at a common place on the cloud, and then manage it. So, it's there in the anvil. We have taken the task of integrating the whole Indian operations vide a suitable ERP. We should be able to have this up and running shortly. Once we have that in place, we will have specific packages for different divisions, wherein we will have space. We are looking at storage, not on a server, but the cloud. So, it's just about prioritising.

ND: Your machines are old workhorses, particularly the flexo presses. How long will they continue to serve you?

VV: I'm a mechanical engineer, and I love machines. For me, the first question is – are my machines hampering my throughput? When I'm hands-on, I get into the depth of it. If I look at the OEE (overall equipment efficiency), I feel that I have good capacity that can be further utilised.

So the need for maintaining the machines to get the throughput and achieve the capacity is not a constraint for me. Hence my priority is optimal utilisation of my current assets/machines, and then the second thing is to invest in new machines. We have got concrete plans for doing it. Very soon, we will be inking an agreement with regards to investing in a couple of the latest machines.

Skanem's Baddi plant is ISO 9001-2015 and URSA certified (Unilever)

ND: The tendency is to go wider and have a number of inspection systems online, including all the decoration part of it.

VV: As I mentioned, we're looking at a CAGR of around 15% in India. So how are we going to achieve that? One, by optimally utilising our resources; and two, looking at the areas of improvement and thereby adding value to the customer. If we want to target new market segments and increase capacity then we need to optimally load all the machines and eventually focus on hardcore NPD (new product development). Turnaround time and giving the customers FTR (first time right) applies to NPD too. So, dedicate resources for that, separate resources for regular production, enhance the capacity, keep up with time and invest in new machines. We have three plants, and we are very clear on where and what we would be investing in, which will take Skanem India to the next level.

ND: Which are they?

VV: We're looking at improving our quality – not only on printing presses but also on online inspections during the settings and during the printing so that we don't end up spending time sorting these products when they reach the finished goods stage.

ND: Given the present market scenario where labels are sold at as low as two paise/sqcm, isn’t the 15% CAGR you mentioned, a high level of growth?

VV: Yes. As I said, we need to move to value-added services. There are a couple of products in the anvil. We are currently working on some niche services that will appeal to our customers. It's a huge market. And today we own around 8-9% of the total market. So there's tremendous scope. Also remember, in India, we are one of the manufacturers for labels who also manufacture applicator machines. So when I say when we are looking at 15% CAGR, I also mean that the machines would contribute a considerable amount of growth for our top line. We are planning to work with market leaders within India and overseas with regard to launching new machines and new technologies.

ND: Why should labellers engage in selling labels at a cost that is lesser than the market rate? Being a very prominent player in the label segment, what would your advice be?

VV: I don't know about others, but we don't do it. I am not a marketing genius or a marketing guru, but I would not do it.

ND: Why wouldn't you do it?

VV: Eliyahu Goldratt is considered to be a learned figure in the field of operations and has authored books about operations and operational excellence. He had asked a very specific question - why do we do business? It's simple. To make profit. If you don't make profit, you're not running a company. There are a lot of stakeholders who are involved with you, your employees, your vendors, their families. If you don't make money for them, ultimately, you're killing yourself, you're killing the dependents, and nobody survives.

So, the purpose of doing business is to make sure that you take care of your stakeholders, and make sure that you give the best. Thus, if you don't generate money from your business, you're not giving it back to society either. For me, any business which is not making profits, I would actually look at it in a very sceptical manner.

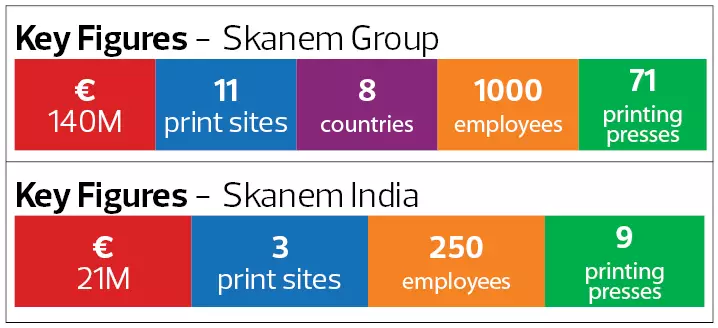

ND: Of Skanem Group’s global turnover of USD 140 million, USD 21 million comes from Indian operations. Why is Indian operation so critical?

VV: The reason why Skanem Group invested in India was because of the potential that the Indian market holds. The sheer size of investment made by the Group in India explains the fact that the Indian operations are quite critical to the whole Group. Operations in a growing market will always be a critical part for the Group.

ND: Skenam has 71 flexo machines operating worldwide, of which only nine are in the three plants in India. So, the other eight overseas plants have got more number of machines. Isn't there's a little bit of imbalance there?

VV: For me, everything is about optimal utilisation of resources. But I would invest in new machines, because I'm looking at a CAGR of 15%. I don't want to be in a situation where I suddenly have an influx of orders and find myself unable to cater to. A stitch in time saves nine. So I would specifically look at the Indian operations and say, I've got resources but I want to first bring it to optimal level. In the meanwhile, I'm investing in new machines, and will then take it forward.

ND: You have nine machines at the three sites and three different sets of operators handling them. How do you handle consistency in production?

VV: It is about putting systems and procedures in place. First, we don't have a large variant of machines. So, the moment your machines are the same, it doesn't matter which machine the labels get printed on, and you can also place your operators on multiple machines. Secondly, we are working to make sure the skill metrics of individual operators are monitored. Most of these operators already have the skill metrics in place. The next step would be multi-skilling, wherein an operator who's working on Gallus should be in a position to also work on a Gidue and Nilpeter. That's the level of multi-skilling we are bringing in.

A section of Skanem's Baddi plant

ND: So what's the benefit of multi-skilling?

VV: It helps in tackling unplanned absenteeism. Any person who has knowledge about that machine can do the job. How does it help us? Our throughput is not compromised. How does it help our customer? Their OTIF (on time, in full) is not affected. Next is upgrading of skills. Normally, people tend to get bored doing the same job, year after year. So multi-skilling will inspire operators to learn and do new things.

ND: In terms of the Group’s overall output, 96% is domestic and 4% is export. Is the ratio same in India as well?

VV: Skanem India caters primarily to India. We export to few SAARC countries and Africa. But most of them are deemed exporters. We don't have major direct supplies.

ND: Are there flow jobs?

VV: Yes, we do have, but very sparingly.

ND: What's your marketing strategy? And how do you make products cost-effective?

VV: All employees are the pillars of the organisation. The revenue is brought in by the robust sales team. And we also have direct contact with the customers. Additionally, we have a corporate marketing team based at the Skanem HQ that actively supports the sales team with tools and marketing materials. We are developing our local marketing team as well.

ND: They say print is a technology industry, not manufacturing. As an engineer, what's your view?

VV: Manufacturing is a different beast altogether. Printing is pure technology. In manufacturing, the technological changes are not so rapid, while in printing it changes at a fast pace.

ND: Any new application development right now?

VV: Yes. There is a process that we follow, where we do an alpha validation, beta validation, incubation, and then launch the product in the market. At present, we are in the validation stage. Again, it has more to do with technological advancement.

I still remember what Mukesh Ambani said around four or five years back that they would go bullish on data. Data is going to be the king. And I agree entirely with him. Policies and strategies are decided by companies based on the data they have. Today, the industry is weak in data. We are trying to arm our customers with the data rather than them being dependent on outsiders. What if a customer or brand owner can get the data directly on his desktop? We already have a complete offering of smart labels within the Skanem Group.

ND: Data often drives digital marketing. Print can also combine data to personalise products. You are one of the few guys who brought in digital printing to produce labels. How are you leveraging this data that you're talking about? (In terms of using the data in producing personalised jobs).

VV: Whatever we have is our internal data. We don't have external data as of today. Currently, we are producing digital application for short-run jobs. Honestly, customised applications are yet to kick off in India. But we have quite a few examples of personalised applications within the Skanem Group.

ND: The recent Share-a-Coke campaign printed with the HP Indigo 20000 was quite successful...

VV: I agree with you. There are strategies on the anvil and in the coming months I'll be able to reveal more details.

The flexo printing division at Skanem's plant in Mumbai

ND: When you talk about customisation, personalisation, a lot of brands come into the picture. Does Skanem discuss with brands to understand what their requirement is? How do you go about fulfilling that?

VV: There's a lot of interaction between Skanem and the brand owners to understand the needs of the customer. We capture the need/voice of the customer with regard to what they are looking for, the target audience they focus on, the product itself, value addition that we can provide etc. This is captured in the voice of the customer. And that is specifically mentioned, when we do the NPD. Once they like what we have to offer, we go in for mass production. We also work along with our customers on improving their sales, end-user experience, supply chain etc. That's how we work.

ND: How do you handle brands which ask for the price cut?

VV: It depends upon what the demands are, and there are a lot of multinational companies where they have very realistic expectations. I have seen that price is not the only deciding factor. The emphasis is on consistent quality, first-time-right supplies, on-time delivery, and price. These are the things, which every brand owner looks for today. They are not looking to cut corners. The concept of – total cost of ownership – comes into the picture. So, to save two paise, we're incurring a loss of Rs 10. This is something that the brand owners have realised.

ND: Trends like consumer becoming the king is driving labels demand. Is that helping Skanem in a way?

VV: The scale of economies will always help any industry. Look at the consumption pattern during the last year and this year. Consumer behaviour is purely dependent upon what stage of the economy the country is at. Consumers are more aware today, and they have the purchasing power. I think it's not the economy, which is changing. It might be the way that you do business which is changing. But any business that you do would require branding, marketing and in most cases packaging. Is the labelling market safe? I would say, yes.

ND: How do you deal with the supply chain? There is a lot of e-commerce angle coming in.

VV: That’s all under our anvil. WhatPackaging? and the whole market would be made aware of it at the right time.

The Skanem plant in Guwahati is ISO 9001 and URSA certified (Unilever)

ND: Also, brand protection and security are things that’s becoming more and more important...

VV: Brand protection is something that we are working on. We have a robust smart labels offering within the Skanem Group, which empowers brands to promote, protect and track and trace, among other tailor-made brand protection solutions. A lot is happening behind a simple piece of printed paper.

ND: It’s said, labels create waste. How does one reduce label waste – for example, going linerless?

VV: One thing which is constant in the whole business is change. So we have to be innovative. We are coming up with ways and means to aid sustainability. One of the examples, as you mentioned, is – going linerless. It is very popular within the food industry in Europe and the UK, and Skanem Group has successfully offered these innovative linerless solutions. We continuously work towards environmentally-friendly and sustainable solutions for our customers.

ND: There are regulations coming in which would require Skanem Interlabels to partner with its suppliers. It could be label stocks, inks, coatings and varnishes that are food safe or non-migrating. Is Skanem doing anything on that?

VV: One thing which we are very clear of is ensuring all kinds of compliances, statutory, mandatory, food safety regulations, and CSR are adhered to. The moment you have these compliances come into play, the industry will become much more organised and a level playing field. We are currently one of the most compliant organisations, and we are also ensuring that our channel partners, stakeholders are compliant too.

ND: Compliance is a challenge, but also an opportunity?

VV: It's a huge opportunity. It creates a level playing field. You have more organised players coming in. There is a lot of responsibility the printing manufacturers have to follow. We make sure that we meet the statutory and mandatory requirements.

A flexo press at Skanem's Guwahati plant

ND: Also, will the price pressure go away?

VV: I always am a firm believer that price sensitivity in the Indian market is definitely going to be there. You know, we as Indians, we love to bargain. Even if you walk into a branded store, the first question we ask is: is there a discount? That's inbuilt in us. So, there will be price pressure, but the effect would come down a little bit more.

ND: Will the present-day economic scenario be a challenge?

VV: There are two ways to look at it. Leaving politics aside, I think today the economy is more poised towards better growth. The reason I say this is that when you have a high jump, you need to have a dip. And this is probably a dip, which will help us stabilise, bring systems in place, look at alternate options, and then take it forward. I believe, we are on the right track.

ND: Three plants already. What next, more plants?

VV: Right now, my focus would be on growing the existing facilities. But after three years, why not?

See All

See All