Slip sheets: Palletless load handling saves money

A slip sheet is an alternative to a wooden pallet with added advantages. Rushikesh Aravkar investigates into the how using slip sheets for assembling, storing and transporting goods can save costs and maximise space utilisation.

30 Jan 2017 | By Rushikesh Aravkar

Slip sheets have been used in India for last 15 years, majorly by the foodgrain, textile and engineering companies for their overseas shipments. Even then this method of load unitisation seems to have missed the eyes of the new generation packaging managers, who are on a constant lookout for cost reduction and material savings.

A casual survey among the packaging fraternity reveals that eight out of ten packaging managers are unaware of what slip sheet is.

Probably, that’s one of the reasons why even after being around for quite a while, a solution like slip sheet with huge potential for cost savings as well as productivity benefits has had a poor adoption rate.

Basics

So, what is a slip sheet?

A slip sheet is a flat sheet of solid fibreboard, corrugated board or plastic (PE) sheet with tabs on one or more sides. It can be deployed as an alternative to the traditional wooden pallets for unitisation of the load during warehouse storage and transport.

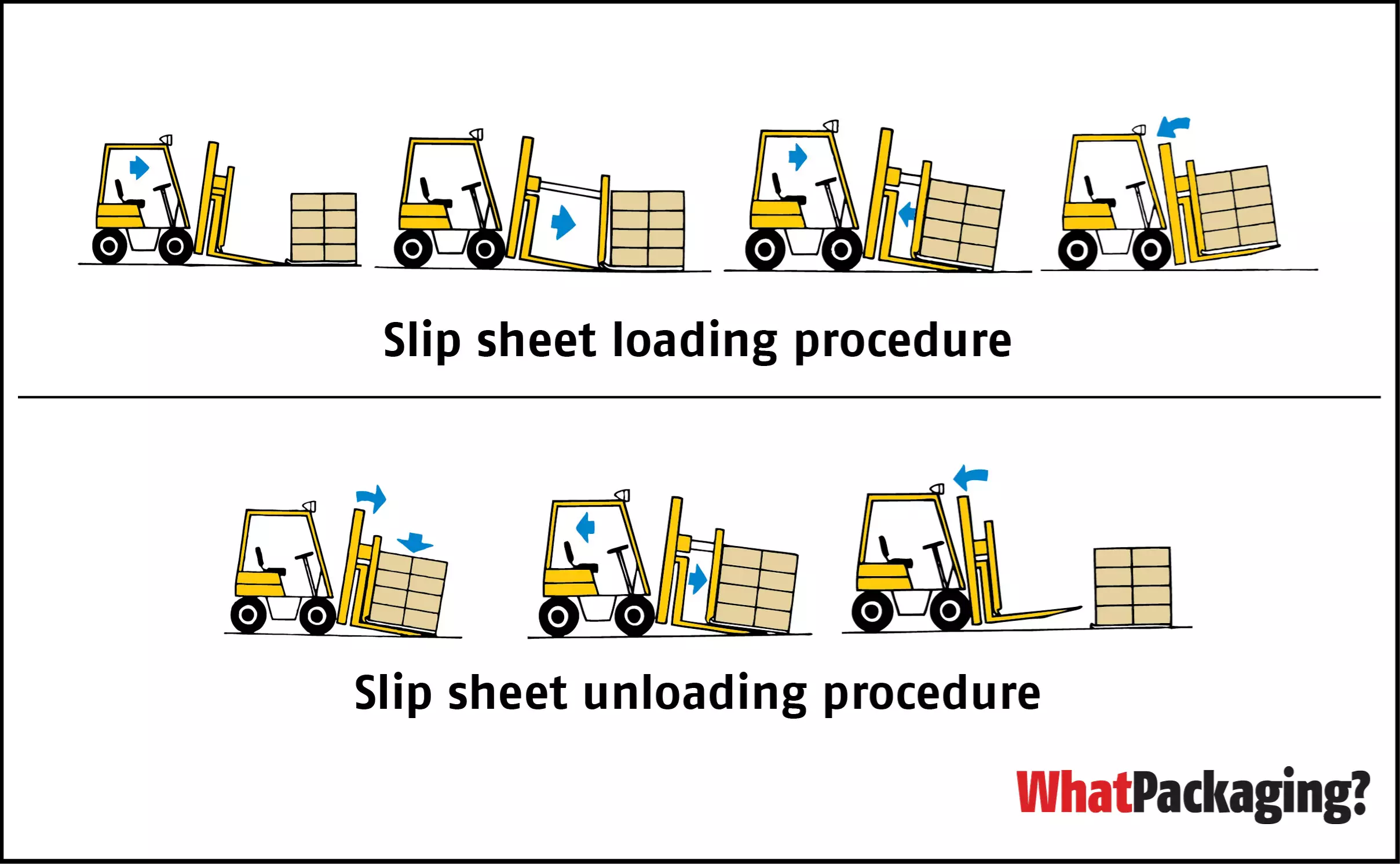

Using slip sheet requires a forklift truck with a special hydraulic push-pull attachment.

The US-based material handling equipment manufacturer, Cascade Corporation with India-HQ in Pune, is one of the suppliers of such push-pull attachment. Explaining the operation, Vishnu Bhagwat, general manager at Cascade Corporation, says, “Once the shippers are stacked with load on the slip sheet, the tab is clamped by a gripper on the hydraulic arms, which then pulls the load onto the forklift tines.”

“Now when the forklift moves to the desired location, the hydraulic arms push the load along with slip sheet off the tines and the gripper releases the tab.”

In order to facilitate this smooth operation, the top and bottom surfaces of a slip sheet are characterised with a dual coefficient of friction (COF).

“Slip sheets are designed in such a way that the coefficient of friction of the top surface is greater than that of the bottom surface. So that it doesn’t suffer load shifting during loading and unloading. At the same time, the lower COF of the bottom surface enables easy loading and unloading when the hydraulic arms pull and push the slip sheet,” says Ganesh Ananthakrishnan, managing director at DSM Agencies, a Chennai-based supplier of pallet stability solutions including slip sheets.

Slip sheet v/s pallet

The palletless handling of unitised goods using slip sheets and push-pulls can save money and reduce damage.

The primary advantage of a slip sheet is the prevention of loss of box compression strength caused because of pallet overhang and deck board spacing.

Adding to benefits of using slip sheet over the pallet, Ananthakrishnan says, “The weight of a slip sheet is significantly lower than that of a pallet and this saves transportation costs. Slip sheets have another advantage of occupying less space in containers thereby more goods can be loaded in a container. Plus unlike pallets, slip sheets do not require fumigation.”

The average cost of a 1200 x1000 mm sized wooden pallet is about Rs 1,100 whereas a plastic slip sheet costs around Rs 300, which makes cheap enough to be discarded after one use.

Ram Srinivas, assistant manager – packaging development, Amneal Pharmaceuticals, who in his previous stint was involved in slip sheet implementation, says, "Slip sheet is a winner, it maximises warehouse space utilisation extensively. “About 100 slip sheets can be stored in the space required for one pallet. Besides this, because pallets occupy large space, companies prefer to stagger the order of pallets, whereas slip sheets can be ordered in one go.”

“Also, pallets can be easily contaminated with rodent droppings and insect as well as residues from previously carried products. Since slip sheets are flat and made of inert materials, they do not provide a medium for infestation or contamination. Slip-sheets also eliminate the fire hazard associated with wooden pallets,” adds Ram.

Besides these obvious benefits, companies can achieve significant logistical savings for high volumes of sea shipments in containers as well as air shipments. Ram explains, “Average weight of a pallet is about 18kgs. Air shipments are charged on weight basis costing Rs 250 per kg for shipments destined to the USA. Therefore eliminating pallets can earn significant cost savings.”

In cases of container shipments via sea, road or rail transport, pallet removal leads additional space in the container, which if used wisely can accommodate more number of shippers per container. (Refer case-study)

In spite of all the advantages, the humble slip sheet finds limited users in India. The primary reason, according to Bhagwat, is a lack of awareness of the concept. “Secondly, the unwillingness of companies to make the capital investment in the push-pull forklift truck is a deterrent. They do not realise that this one-time investment with ROI of less than three years can earn huge logistical savings.”

Ananthakrishnan says, “The Indian markets are used to pallets and the slip sheets being a relatively new concept is slow to take off. The adoption of slip sheets in India is driven by the end-user rather than the product manufacturer wanting to shift to newer technologies. If end-user decides not to accept goods on pallets and, then customers will switch to meet their customers’ requirements.”

In last 10 years, Cascade has sold more than 80 machines in the country. “However, this situation is changing,” says Bhagwat. “Year on year, the number of installations continue to surge.”

Case-study: Bengaluru-based food manufacturer saves millions with slip sheets

A Bengaluru-based food product manufacturer, which exports to the US market, recently implemented slip sheet for one of its high volume product, which is shipped via sea transport.

The company ships approximately 45,000 packs per month in 1,872 shippers on 104 pallets in three containers.

In December 2016, after continuous trials for over seven months, the company switched to slip sheets. It has invested in two sets of push-pull attachments one for the plant in Bengaluru and the other for the warehouse in the USA costing Rs 25-lakh each.

Eliminating the pallet, the company was able to add two extra layers of shippers per container and thereby it was able to ship all the shippers in only two containers.

Not only did they save the material cost with eliminating the pallet but also earned logistical savings by reducing the number of containers required. The company has earned monthly material and logistical savings of worth Rs 6,42,040. It aims to recover the ROI in about eight months.

(To download the detailed cost savings calculations for the case-study fill the form below)

See All

See All