Spotlight on 10 packaging players at PackPlus

PackPlus 2017 opens this week on 3 August in New Delhi. Rahul Kumar speaks to 10 top exhibitors at the show and understands what to expect at the four-day show

31 Jul 2017 | By Rahul Kumar

Bizebra India

Kiran Bidvai

Our industry will grow by 20%. This includes our company thanks to our new and existing products.

Our company specialises in check weighers and metal detectors. We are based in Navi Mumbai and recently, we have made inroads in the spice segment and dairy segment with its check weighers, metal detection and X-ray devices.

One technology which is under-estimated by our industry is the technology applied in after-sales service. We have the My Bizerba concept where we have automation in service offerings.

Boston Polymers

Garvit Garg

"The Indian packaging industry is growing," said Garvit Garg. He added, “Compared to FY15 statistics, Indian packaging industry is worth USD$32 billion. If we see the current statistics growth rate, this figure will be doubled by 2020.”.

In today’s scenario, most of the industries such as FMCG, pharmaceuticals, etc, are using plastics for packaging. Due to its innovative technique and cost effective methods, plastics are the de facto technology. In FMCG sector, plastics industries are more concerned towards hygiene and increased the shelf life of the product. This gives a boost in the FMCG sector to pack with the help of plastics products.

Boston Polymers has products like Silage Film used in the packing of agriculture products, anti-static films used in the industries, VCI film for protection of product from rust.

As a new entrant in the market, we have focused more towards quality packaging products. That too by a manufacturer from North India.

BST Eletromat India

Ameya Dhumal

We expect the market to grow. And the increased opportunities in India will give a boost to the Indian currency to be stronger in the future. This will have a big impact on the packaging industry in India and the Asian market. The implementation of GST will also have a long lasting impact on the overall Indian economic conditions.

Even after the demonetisation slump, we have managed to achieve our business objectives. The entire credit for the achievement goes to our team at Eltromat and our customers who believed in us when it comes to quality assurance systems provider in the Indian market.

I feel many converters and printers in India are not aware of the potential and endless possibilities with BSTe products on their presses.

Colour monitoring and colour measurement consistency are not given importance as it should have been given. BSTe iPQ Spectral is one such tool that will help printers/ converters to unleash the potential of this technology. BSTe iPQ Spectral efficiently supports complying with default colour standards by carrying out an in-line measurement within the printing machine. Perfect comparability with hand-held offline devices and inline spectral measurement system working within the XRGA standard and along with a partnership with X-Rite.

I like what brands like Absolut and Bira 91 do with the products. Also Neuhaus Belgian Chocolate, especially their truffles box. The reason being these brands understand what they stand for in the minds of their customers and at the same time, they value customers’ expectations about their product. These brands have been setting trends in innovating the packaging in their respective product category and clearly are the market leaders.

The five things I would like to alter in our industry is honouring the credit period and taking services for granted; expecting prompt service every time and that too free-of-cost; over-reliance on manpower for every process; finalising quality assurance systems on basis of price whereas it should be always on the basis of quality and performance.

Today, BST Eltromat is a pioneer in quality assurance system for web processing industry worldwide. We have been providing simplest solutions even for the most complex applications and our customers have been appreciating this over a period of time. This year’s edition of PackPlus is also a very important platform for us to get our customers closer to the BSTe iPQ Center the most intelligent and integrated quality assurance solution currently available in the market.

BST Eltromat is planning to demonstrate iPQ Center with iPQ Check and iPQ View modules during PackPlus 2017.

Ganter India

Ram Grover

The Indian economy is growing and so is the packaging industry. As growth rides on increased industrial production and international trade, demands on package converters have become more intense and sophisticated. Within India, increasing penetration of organised retail and increasing preference for branded products has added fuel to the demand for flexible packaging solutions. Machines and advanced technologies for the flexible packaging industry have to meet the rising requirement.

Across industries and around the world of standard machine elements, Elesa and Ganter has carved a niche for itself. We are renowned for our quality and innovation. We realize the growth trends and unique demands from packaging industry and have developed customised solutions for our customers.

Today, Elesa and Ganter offers wide range of 50,000 standard machine elements worldwide. The products offerings are: operating elements, machine elements, indexing elements, clamping knobs, clamping levers, U-handles, fixed, revolving, fold-away handles, control elements, rotary controls, levelling elements, joints, hinges, hatches, hook, toggle and power clamps; plus accessories for hydraulic systems, and tube clamp connectors, castors and wheels, retaining magnets etc.

Kiran Consultants

Gaurav Bansal

We are very enthusiastic about the growing packaging market, new eco-friendly packaging innovations and increased applications of packaging in the supply chain replacing loosely sold material. With the growing volumes, comes issues of lot traceability, planning, wastage control, MIS, accounting where we come into play and help the manufacturing industries streamline their end-to-end processes.

Kiran Consultants will showcase Flexibiz during PackPlus. The show is a packaging and supply chain event, where we get to meet a lot of pharma and food manufacturers looking for packaging materials etc. We wish to help this segment by providing our CRM Solution for distribution. It is an order booking mobile app to assist the retailers and stockists to book their orders to the C&F/Distributor. For the packaging and label manufacturers, we have an ERP Solution.

The company has had a successful 2016 during which it implemented CRM Solution for distribution at Virbac India – a healthcare company. This means, 300 sales reps, area managers and stockists send their orders to C&F thru mobile. Plus the sales reps can book their daily time attendance through the mobile phone.

The usage of IT to manage the business processes will boost the industry process. He says, "For pre-sales we have CRM Solution managing leads, estimates and quotations. Post-sales we have trouble tickets management, bill payment collection system. ERP manages the order booking, planning and production, dispatch, and accounting." ERP, he feels, caters and copes with all pain areas and intricacies.

Narang Sons

Amandeep Singh

The Indian packaging market has grown multiple folds in the last ten years. And it still has the potential to keep expanding in coming years. After the FMCG sector rapidly adapted to newer packaging options, this industry has got a boost in sales in the field of printing and packaging. This has supported even the small players of the market. As the urbanisation is taking over in the rural areas of the country the demand for packaged products will rise to its all time high. That is why I am very positive and optimistic for my products to have increased demand to meet the market requirement.

Narang focuses on two type products. One of our product range in mostly used in BOPP and similar packaging products (it is used in rice, atta, chemical, fertilizers, etc. 5/10/20 kg bag packaging). The other product range in used in the paper bag and corrugated boxes.

Our products come under a very small scale industry and had very low value in the total value of package material. There are no organised players in the market. As in the last decade, our company could see the potential in this growing market, we have focused on quality and supplies of our product. This has helped us to rise as an organised manufacturer who can meet the expectation of our clients and emerging market.

As our products are from a small scale industry, most of the times the people of the packaging industry find it difficult to procure our products ending up with some unprofessional suppliers who do not have any knowledge and expertise in our field.

In our field, we are deploying the latest available technology to manufacture our products. Adaption to newer products is very quick if they are better than the older options available. So there is no under estimated technology. The only difference is that it may take a bit extra time for any new thing to come in market and mark its presence.

PR Packaging

Vishesh Gupta

Our current demographic dividend is a competitive advantage among all other countries. Consumerism is bound to grow as we see higher and higher positive sentiment in the country. More people, more products, more packaging. The Indian packaging industry will grow strongly in the packaged food, luxury and high-end, and consumer electronics segment.

At PR Packaging our focus is on cosmetics oriented lamitubes and rigid boxes. In 2016, we diversified into lamitubes, and expansion in rigid boxes.

One technology which is under-estimated by our industry but has a great future is ... data usage and artificial intelligence. We see other industries capturing this technology in its prime time, but not the printing and packaging one. What kind of data is to be collected, how to do analytics on that, real time MIS, making predictions using data from the past, all this can be very important.

Cosmetic majors like Emami, L'Oreal use very subtle packaging along with a blend of powerful statements and innovation.

One thing about our industry ethos, which I would like to change is, introduce a healthy competitive spirit focussed on innovation and value addition. The fact is everyone's self-centered, it's just that the radius of the circles differs. We all need to increase our parochial views and think about making a dent in the packaging ecosystem, be it through IoT, material exploration, or collaborations.

Quadtech

Craig Du Mez

We expect the packaging market in India to grow somewhere between 10-15% in the coming year. That optimism is driven by the growing trend of supermarkets and packaged food habits. We believe the market for this is largely untapped, and local demand is definitely on the rise. Some factors that contribute to increase buying power include a stable political situation, two years of good monsoon seasons, and major tax reforms.

In 2016, we opened a new, modern office space for QuadTech India. This move and expansion are a large step forward in better serving our customers. By creating a space that is both welcoming and functional, we are better equipped to demonstrate QuadTech print technology solutions. We are also very excited to add local assembly capabilities and a local 24/7 help desk team to continue growing and extending our service capabilities.

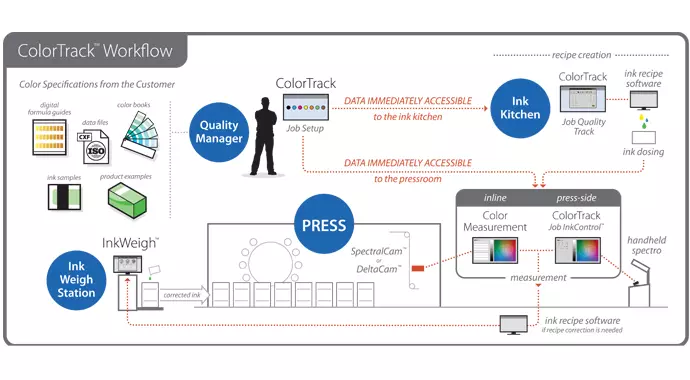

From a product standpoint, our product launches demonstrate an unprecedented level of innovation, bringing never-before-seen solutions to package printers. Since Drupa, we’ve added seven “colour management breakthrough” features to our ColorTrack solution, some in combination with our new, highly affordable DeltaCam inline spectrophotometer technology.

Our new ColorTrack software is not yet well known, but people who have seen it immediately understand the impact that it is about to have on the industry. At Drupa 2016 and again at China Print 2017, our workflow solution kept our stand full of visitors from beginning to end. ColorTrack is a unique industry-first technology that is highly adaptive. With a variety of options for hand-held and inline configurations, the software facilitates fast, accurate press-side correction of ink formulations. Early adopters will have a definite competitive advantage, as we expect ColorTrack to become widespread once the industry has been exposed to the clear benefits. With the rapid growth in the India packaging market, now is the time for printers to grab market share.

To compete worldwide, there is a great need for organisation and standardisation with package printers. Brand owner quality and consistency expectations are very high and becoming increasingly complex. Printers who can not only achieve high-quality print—but also prove their performance to print buyers—will have enormous opportunities for new business and profits. Print quality workflow systems have shifted from being a “nice-to-have” capability to a must-have technology, enabling printers and converters in an ever-competitive market to drive efficiencies, increase print quality and critically, increase profitability.

Regent Plast

Kartik Deora

Regent Plast’s star product is the innovative wood finish cream jars. The company with a factory in Umbergaon launched multi-layer plastic bottles in 2016. The advantages, according to Deora are leak-free bottles, masterbatch savings and improved quality of packaging.

Regent offers a large portfolio of ready packaging. This means our customers need not invest in their own moulds. This is a huge advantage for start-ups as well as existing and large companies launching new products.

One technology which is under-estimated by our industry is in-mould labelling.

I think brands like Castrol with their attractive packaging genuinely boost product appeal.

Our industry is bedevilled by under-cutting on pricing rather than investing the money to build a better quality product (i.e. ploughing profits in purchasing higher technology equipment).

Uflex

Sachin Dahake

The Indian market growth will be more than 1.5 times.

India’s largest flexible packaging player will display a laser engraved printing cylinder at PackPlus. At Uflex cylinder division, we have done technological innovation which is beneficial to the printing and packaging industry. One of it is the low ink consumption printing cylinders which result in cutting manufacturing cost.

Biodegradable packaging is the most under-estimated technology in our industry.

I genuinely like what Paper Boat has done. It is a revolution in liquid packaging.

One thing I would like to alter about our industry is long credit period.

See All

See All