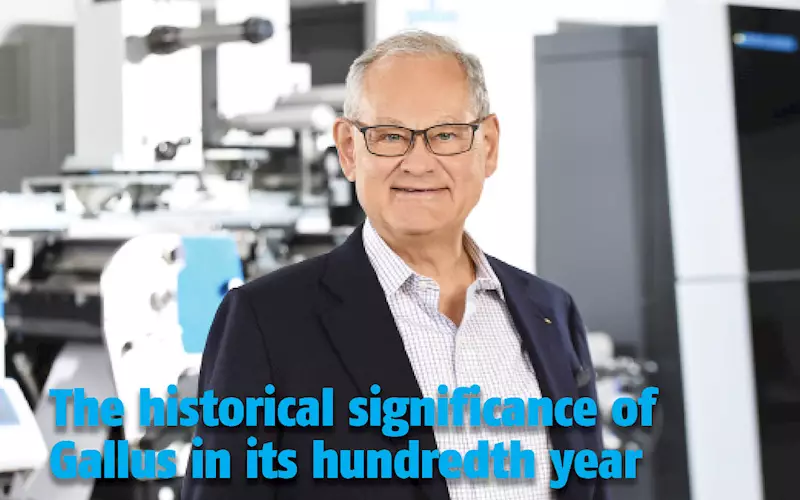

The historical significance of Gallus in its hundredth year - The Noel D'Cunha Sunday Column

2023. Next year we can look back at 1923. At the formation of a small, well-structured business. When Ferdinand Rüesch, Gauger, laid the foundation for the Gallus Group.

Ahead of the centenary year, Noel D’Cunha catches up with Ferdinand Rüesch of Gallus at the PrintWeek booth during the Labelexpo show and discusses all things labels.

Read on...

13 Nov 2022 | By Noel D'Cunha

Noel D’Cunha (ND): 1923 marked the formation of a small, well-structured business, Ferdinand Rüesch, Gauger, that laid the foundation for the Gallus Group. You took over in 1990-1991. What role did Gallus play in the subsequent years in the flexo arena, and its thrust in multiple markets, including India?

Ferdinand Rüesch (FR): Gallus recognised the trend from letterpress to flexo and the growth of UV Flexo early, and therefore, acquired Arsoma, an innovation leader in flexo press manufacturing way back in 1989 to get a foot in the door of the new trend the flexo technology. The challenge for Gallus has been to make UV flexo printing and rotary screen printing compatible and productive. The challenge was to have all the different inks, UV flexo, and screen to be compatible with each other, so that you could print screen over UV flexo, etc. Step by step, the prices of UV inks came down. Only direct food labels stayed with water-based flexo. In India, Gallus customers switched quickly to UV flexo.

ND: India is one of Gallus’ favourite markets. Why?

FR: It is the Gallus family in India, where we have a family spirit all over the label industry. Even though some of us are competitors, all industry partners aim for the same goals, have a great time together, and have deep respect for each other. It is a country where emotions are lived, and they strengthen relationships. The staff and colleagues of Heidelberg India offer consultancy on all topics related to the label printing industry.

ND: The EM 280 flexo press is a legend in India. It’s an oft-asked question, but what’s your answer to why it’s a special press – in India and worldwide?

FR: It’s because the machine is easy to operate, easy to fix, easy to learn, easy to adapt, easy to extend, and it works all over the world and in every environment. This machine has big footsteps not only in India, but worldwide.

Gallus Labelfire

ND: You have been a frequent visitor to India, and your Indian customers. How has the Indian label manufacturing unit evolved over the years?

FR: Indian label manufacturers learn fast. They often went to Switzerland and Europe and exchanged their thoughts with the label printers here and implemented their findings very quickly.

ND: We hear India will install a never-before Gallus flexo press somewhere in Ahmedabad. Is it going to be the first RCS platform?

FR: We are not allowed to talk about this at the moment. There will be a right moment to announce this.

ND: Industry 4.0 (4IR) has been a talking point for over a decade and has been evolving. What has been Gallus’ approach to manufacturing which has been successful, and which the label manufacturers in India can emulate?

FR: Gallus offers electronic interfaces that enable our customers to collect machine data directly and automatically out of the control system. This data can, for example, be used to optimise the production workflow, create productivity charts and feed them into an MIS system.

ND: It is said that the pandemic has created challenges, but it has also accelerated many aspects that are key to 4IR. With the experience you have, what should the Indian label manufacturers do?

FR: The actual Gallus portfolio was developed to minimise energy consumption and waste and to maximise production efficiency. Short web paths and modern register control systems are reducing waste and enabling a reliable production process. The new design- and operating-concepts guarantee short makeready times, ease of use and high efficiency. Electronic data interfaces enable better monitoring of machine performance and can help increase overall equipment effectiveness.

Gallus Remote Service

Printing processes can be easily retrofitted, making the machine ready for future requirements and challenges.

In addition, even after installation at customer sites, our presses are continually optimised, and the print process is frequently examined to determine material and energy consumption.

The current UV systems can be upgraded to LED without replacing the ballasts. Depending on the application and age of an existing machine, a change of the drying system, for example, to LED (approximately 50% energy saving), a control system upgrade to extend the operating time or a retrofit of a register control system to reduce waste may make sense.

ND: Today, the pursuit is on cost-saving and productivity. It is about creating very lean and linear supply chain designs. But there are obstructions. What does one do? How does Gallus manage these disruptions?

FR: It is to find the balance between cost saving, productivity and conscious planning and always have a bit of reserve in mind to add a bit of cushion at the right planning step to help overcome human and realistic mistakes which happen in daily life. Please be prepared for this event if delivery gets too late for a reason today.

Gallus has searched for where to add the cushion, where it is possible, and sometimes you have to take unusual ways to find the right part. But besides this, if electronic parts are not available in today’s supply chain and shortage, you have to search for them all over. If it is not possible, it is, unfortunately, the moment to accept the non-availability.

ND: If you were asked to name five label manufacturers in India, which are the ones that would come close to being a 4IR factory – resilient, connected and customer-centric?

FR: Every manufacturing industry revolves around 4IR – which is one of the key success factors. Many of our install base customers are operating with 4IR concepts and are successful, and picking an individual one is a tough task. I think it is defined by their hard work and success.

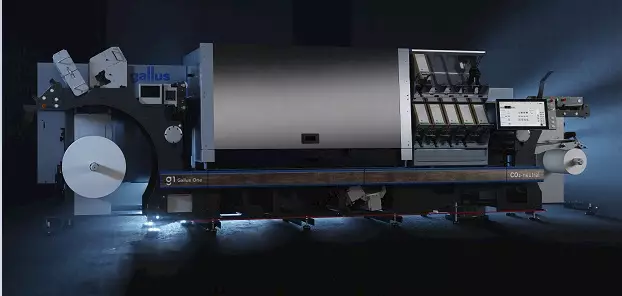

Gallus One

ND: Digital first has become the mantra. Gallus One is a digital offering from Gallus. Much of label manufacturing is conventional flexo. Where does digital label printing fit in? Why should one think of Gallus One?

FR: You should consider digital to remove the TCO barrier. With Gallus One, Gallus offers the machine system with the best price-performance level – the ratio between costs (TCO) and output (performance). In segments such as food and dairy, retail and logistics, beverage, pharma and household, the run lengths are beneath 10,000 linear metres. These are exactly the segments where Gallus One fits in with a very attractive TCO. The overall basis is the Gallus One EcoSystem. Gallus and Heidelberg own all important technologies like press (the basis is the Labelmaster), workflow (Prinect), Ink (own ink development), predictive service (minimise unplanned downtime), and inkjet technology (this is a major pillar of the machine. It’s the basis for a high level of automatisation.) We ensure short setup time and high output with our unique vision system, innovative Ultrasonic Cleaning System, and many more.

Gallus Labelmaster

ND: That said, conventional, digital, combination – what and where is the future of label manufacturing?

FR: The future of label manufacturing is that you will have more possibilities to use the right printing process in combination with the right printing machine. So that means it will go step by step toward digital. Conventional will always be there, but many jobs will move to the kind like the new Gallus One machine.

ND: Gallus is not just about flexo presses. What are the other specialisations from Gallus?

FR: Service, application know-how, the Gallus Family, and the people. You are connected to the printing industry around the world. Gallus has an ear for the customer, we like to listen to what he needs and make it happen.

ND: In mature markets, such as Europe or the USA, the per capita consumption of self-adhesive labels is more than 10-sqm. In India, it is still less than 1.0-sqm. India’s consumption is estimated to be 1.2-bn-sqm and the market size of around Rs 6,000-crore. There is still great growth potential. What is your assessment, and which growth areas should the label converters look at?

FR: The label printer should look at specialities, complex labels with functions, multi-layer, and coupons; he has to find a niche where he can be the specialist.

ND: Finally, your outlook for 2023, Gallus’s centenary year, and the Indian label industry?

FR: It’s unbelievably great to celebrate with the Indian label industry the 100th anniversary of Gallus and have an outlook on the future of label printing and the next 100 years of Gallus. Despite the external economic situation, we are confident to celebrate in the usual Gallus manner together with the whole Gallus family.

See All

See All