The pandemic is driving short-run prints - The Noel D'Cunha Sunday Column

Around the world we are seeing large, offset printing production being replaced by short-run jobs. “I think this trend is here to stay and will continue to develop even more in the future,” says Eijiro Hori, president of Horizon Group.

Read on...

30 Jan 2022 | By Noel D'Cunha

PrintWeek: Two of the top five moments of 2021 for Horizon were — one, the Horizon Smart Factory 2021, a week-long exhibition where we team up with both print and tech companies to show how our devices can be used to automate the printing or book-binding process; and second, the growing interest for smart-factory innovation. First, let’s talk about the exhibition?

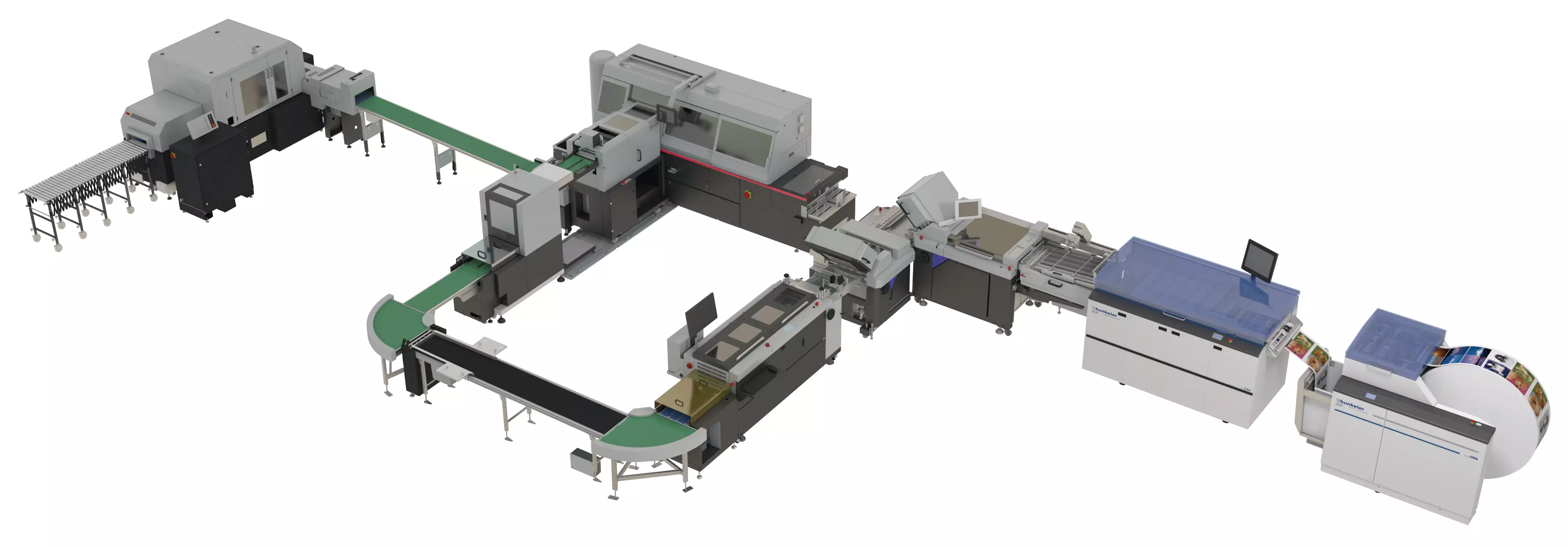

Eijiro Hori: In the Horizon Smart Factory 2021, we teamed up with both print and tech companies to show how our devices can be used to automate the printing or book-binding process. We opened up our facilities for in-person visits domestically and offered a wide range of tours and demonstrations online for anyone who could not make it in person. There were over 800 in-person visitors and 4,700 registered viewers for our online tours and demonstrations, which were offered live in Japanese, English, and for the first time ever, in Mandarin.

Click here to the see videos of all the tours and demonstrations.

PW: The second, growing interest in smart-factory innovation. Can you explain?

EH: 2021 was a year of resilience and recovery with the Covid pandemic affecting everything from a trip to the local grocery store to the global supply chain and international travel. One unexpected trend we’ve noticed is a growing interest in smart factory innovations: with social distancing, in-person working limitations and other such Covid prevention measures becoming a necessity, we are seeing new interest in our automated, smart-factory-ready devices from printers and binders all around the world.

Horizon solutions are a perfect fit for these current trends because efficient production can be maintained with fewer workers and manual adjustments than would be required conventionally. With the lingering pandemic and shrinking population of skilled workers, this is a trend we expect to continue for the time being.

PW: With the lingering pandemic, 2021 became a year of perseverance. How did 2020 pan out for Horizon?

EH: Like Japan and the rest of the world, 2020 was a difficult year for us, but policy changes and innovations we implemented early on are beginning to bear fruit and are providing hope that 2022 will be a better year. No one knows how long the pandemic will last, so it is up to us to adapt and make the best of our current situation and resources.

2021 showed how crucial it is to be able to adapt to new situations and challenges — not only on a personal level, but as a company too.

PW: For example?

EH: More than half of Horizon’s sales are overseas. So, the pandemic has impacted us greatly. Facing the difficulty of international travel, we’ve had to change the way we work and interact with our regional dealers and their clients overseas. We have invested substantial time, effort and funds into advancing the technology and training for our sales and customer support teams so that they can carry out their duties virtually. Some examples include online training classes for overseas system operators/engineers, virtual demonstrations of our devices for potential clients, and reliable customer support from our World Support Centre in Kyoto.

PW: What are the positives of these initiatives?

EH: We are seeing sales of new products that were released after Covid started, which show how effective these new methods and technology are. Even when the pandemic ends, I don’t see us ending these services as they have become essential for future sales.

PW: About Horizon’s Indian operation? Your assessment of India’s growth prospects?

EH: Unfortunately, the pandemic forced all of our business operations in India to come to a halt. However, we have been able to recover some ground since its beginning and are gradually rebuilding as conditions are improving. In fact, we are seeing more interest in India for our systems because of their automated processes and ability to do variable, short-run jobs. As India is adapting to a life with Covid, print shops and binderies are looking for devices that can be operated with as few workers as possible.

We see this as a sign of potential growth, and plan on answering this opportunity by providing more virtual demos and support for all interested parties.

PW: In order to create a positive impression on consumers, brands are seeking more and more from print and packaging. Speed to market, flexibility, profit-centric approach and sustainability has become the new normal...

EH: Just as we’ve had to adapt in order to survive the pandemic, the printing industry will need to change in order to meet these new demands if we want to survive. Around the world we are seeing large, offset printing production being replaced by many short-run jobs. I think this trend is here to stay and will continue to develop even more in the future.

PW: Such as?

EH: Print shops need to be able to handle a diverse range of jobs with fewer workers and a smaller margin for error if they want to make a profit, which is where Horizon solutions can help. Our solutions are perfect for such jobs as they automate both the job setup and production processes —essentially allowing print shops and binders to finish a wide variety of jobs in a quick, efficient manner with lower labour costs and chances of human error. Making a new standard for the print/finishing process is the only way our industry can keep up with modern trends.

PW: What should the print strategy be? How can print enable brands to thrive in unprecedented times, going beyond the function of their product or service?

EH: The foundation of any company’s marketing strategy should be in the quality of its product or service. However, to differentiate yourself from competitors it may be necessary to promote other qualities of your company/product that don’t always relate directly, but improve your brand’s credibility and show what the potential customer can gain from your product — even if it isn’t something concrete, like a good feeling or sense of wonder.

PW: Sustainability has become the buzzword, even with Indian consumers. One study showed that 77% of these consumers invest time and money in companies that try to do good. Three sustainable actions you have undertaken in the past year that you can share with us?

EH: At Horizon, we are committed to sustainable practices.

For one, our systems are developed and manufactured in an environmentally friendly manner. Our Biwako manufacturing plant is located next to Japan’s largest lake, Lake Biwa, and we make it a priority that all of our manufacturing and waste management practices exceed local standards so that the beauty of the lake can be enjoyed long into the future.

We are an official endorser of the Mother Lake Goals (MLGs), which are similar to the UN’s Sustainable Development Goals but for the surrounding Lake Biwa area, and actively participate in volunteer clean-up efforts around the lake.

In addition to the local environmental practices, we strive to decrease worldwide paper waste by creating user-friendly devices that allow operators to set up jobs with the least amount of paper waste possible. At our Horizon offices, we ourselves engage in sustainable practices and make sure that our paper waste is properly recycled so it can be reused in the future.

PW: In their report from 2011, Ogilvy and Mather define “green gap” as the gap between consumers’ green intentions and green actions. Is there such a gap between what our industry talks about and the rest of society?

EH: I think there is a “Green Gap” between industry insiders and the general public. The problem is that industry terms aren’t always used in everyday life, so it’s our job to explain them in a way that can be understood universally. New ideas aren’t always accepted right away, so continued, periodic reinforcement of such ideas is quite important if they are going to become accepted.

PW: It’s been tough for the print customers across the spectrum — meeting challenges of print and packaging fulfilment for those who have thrived, and those who were on the margins. Are there examples of resilience and innovations from your customer's side?

EH: In the US and Europe (even here in Japan), I hear printers and binders are seeing a decrease in skilled workers as the general populations are shrinking and the pandemic is keeping workers at home. This has helped shift attention towards our devices as they can be used to automate the whole finishing process. I have heard of success stories where binders have implemented our systems along with additional robotic technology, like robot arms or automated guided vehicles (AGV), in order to operate complete production lines with two or three workers.

PW: And finally, your plans for 2022?

EH: I will be watching the global pandemic closely, but regardless of how things turn out, Horizon will continue to promote the concepts of smart factory technology and aim for further automation of the printing industry.

For 2022, we will be releasing a few new products to the market and actively promoting them to our dealers. At the same time, we will continue to research and develop new systems that can handle the demands of the future, possibly even wander outside of the printing industry. We plan on existing 50 years in the future, adapting and making necessary changes that it will take to survive as a company.

Rapidfire questions

- How do you unwind?

I indulge in driving and playing golf.

- Favourite film(s)?

Bohemian Rhapsody and A Man Called Pirate.

- Three books by your bedside?

大本営参謀の情報戦記 (Daihon'ei sanbō no jōhō Senki) (Information warfare of the chief of the main office) by Eizo Hori; 革命前夜 (Gémìng qiányè) (The eve of the revolution) by Shinobu Suga; and 仏教の本 (Bukkyō no hon) (Buddhist book) by Yukie Ota.

- One thing about the print you always utter in a public forum?

Good can come out of misfortune.

See All

See All