Women power: Withering the storm

There are numerous dangers facing a business, but you have the power to act.Lalitha Aluri, managing director of Nampally-based Balaji Scan in Hyderabad did

10 Jun 2019 | By PrintWeek India

Balaji Scan was established by Aluri’s husband Prasad in 1995, with four partners. The firm did well for the next four years until the partners decided to part ways in 1999. “These partners had other business where there was cash flow, and did not see the same kind of cash flowing in Balaji Scan. The print business then was on credit-basis, and the period was as long as six months,” says Aluri.

The split meant the partners share had to be settled. “That was a setback,” says Aluri. “It also meant that my husband and father-in-law had to manage the business.”

The business transition was not as smooth, which forced Aluri to join the business. “We upgraded our scanning kit, and strengthened the design house. We had to work overtime, at times 18 hours a day, to come out of the debt,” she says.

Few years down the line the field of platemaking underwent a dramatic change. India was introduced to CTP. “We were at the dead end of drum scanning technology,” says Prasad. “Instead of investing in a platemaking kit, in 2004 we decided to diversify into printing.”

It was Aluri’s idea. The scanning business was getting saturated, and if Balaji had to survive it had to enter into the printing business, says Aluri. “Reading books was my hobby since childhood. I had a library at home. I used to write poems, too. After joining Balaji, I saw many eminent writers come and get their book work done. For me that was exciting. Print became my vision.”

The Mitsubishi 1000 Diamond installed in 2007 at work

There was initial hesitation, as Balaji became a client to the clients they served. "But we went ahead," Aluri says.

Balaji Scan retained the name and started taking print orders. The firm’s business was like a barter system where it provided scanning services to the same customers from whom it sourced it print. Payments were adjusted. “Unfortunately, sometimes, we could not get our urgent jobs delivered in time, because for the printer, he knew, the payment of this job will be adjusted against the scanning service we provided,” says Aluri.

This payment method prompted Aluri to invest in a printing press. It was a Komori Lithrone 426 first, and a year later a five-colour Komori Lithrone. In 2007, Balaji invested in its first brand new Mitsubishi Diamond 1000. “The idea of going for a brand new machine came during our visit to Drupa in 2004. But we did not have the resources then. When we did, we installed the Mitsubishi Diamond 1000,” explains Alluri.

Lean manufacturing connect

Aluri is the president of Confederation of Women Entrepreneurs of India. She came across a cluster development concept, promoted by the Government of Telengana, which offers schemes with funds and subsidies.

Aluri says, “I spoke to a few like-minded printers about forming a cluster. That’s my immediate goal.”

And so, Balaji Scan is part of another cluster of nine members which are implementing a lean manufacturing process. It is called the Hyderabad Cluster. “We are at stage five now,” says Aluri.

The Government of Telangana is spending Rs 3.75-lakh on each company to implement this. The objective is: to eliminate waste.

“Many printers keep large inventories of material fearing that the prices will go up. Here, we eliminate the need for large inventories. We keep only as much as is needed,” says Aluri.

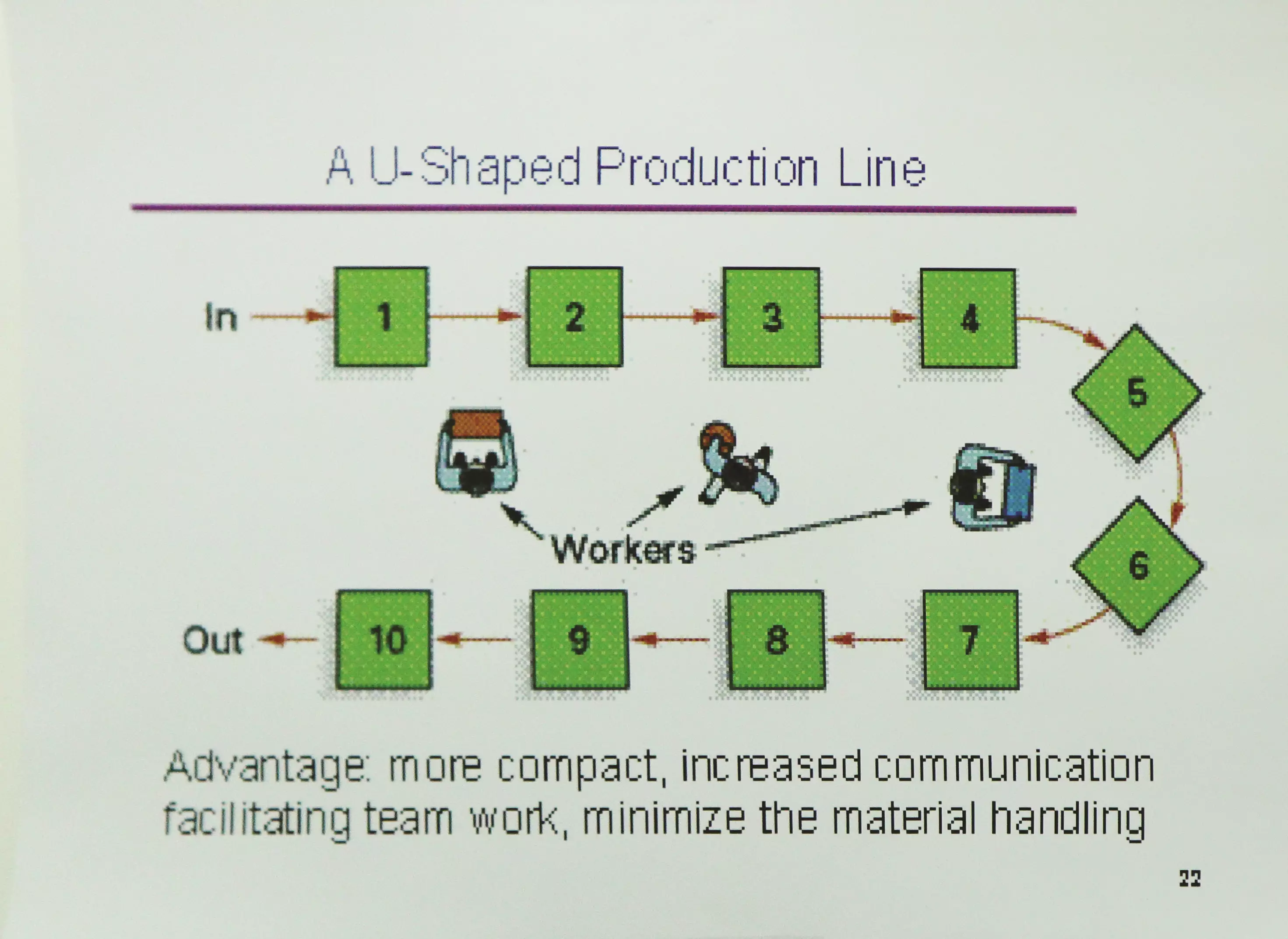

There are standard operating procedures, which each of the companies needs to follow. For example, the departmental in-charges have to follow a set procedure and it includes movements of man and machine.

It’s been two years since Balaji has been implementing the lean manufacturing process.

Aluri says, “We have been able to save 1,000 sqft space by proper designing of the shopfloor. We have now added a punching and a six-clamp folding machine installed in the same space.”

In terms of monies, Aluri says, at a rate of Rs 20 per sqft, we have been able to save Rs 20,000 per month and generate additional revenue from the new machine.

In the last two years, Balaji has been able to save waste and generate revenue worth around Rs 25-lakh.

Lean manufacturing SOPs: Balaji Scan is part of a nine-member cluster which implements a lean manufacturing process called the Hyderabad Cluster

Confidence and complacency

Balaji specialises in commercial printing, and most are job works. 80% of its print runs are below 10,000.

Balaji’s tagline – A roof for colourful printing, it’s not just colour, but quality and consistency too. That’s one of the reasons the company has invested in a Kodak Trendsetter platesetter and moved from violet plates to using TechNova’s Elite thermal plates. “It’s the stability of dots, which delivers quality and consistency. Plus we can repeat the jobs using the same plates, if the customer needs a reprint,” says Prasad.

Balaji’s ground plus three-storey building also has a complete binding unit including a Welbound 2000 perfect binding machine.

While Aluri is confident of the print capabilities and service of the Rs 6-crore turnover firm, staying satisfied with commercial print jobs is not the way to go, she says. “I have been working with great passion, and I don’t regret having joined the print business. However, we are now in a phase, where we have to look beyond commercial print business.”

Prasad agrees. He says, there’s a difference between confidence and complacency. “We don’t dictate to the market, we deliver what the market wants. Our next move will be towards packaging.”

Besides, there’s no fun in doing monotonous and mundane jobs, says Prasad. “The cost of raw material is increasing by the day and the margins are shrinking.”

Why packaging?

In the last 10 years, the city has grown manifold. The world’s biggest IT companies have their operations here. There are pharma companies. And there are small players too.

The advantage of doing packaging work, unlike commercial printing jobs, is that one can approach the customer directly. Plus, commercial printing, unlike the stable packaging market, is a business in flux.

Prasad says, “There are small local players, who want their products to be well packaged. Today, small businesses do not want to pack their products in brown paper packs. For example, a small sweet shop owner wants MetPET packs, or a small biscuit manufacturer wants his products to be packaged with all value-adds like spot UV printing.”

Hyderabad is famous for biryani, and the employees of large IT companies, who do not stick to fixed eating hours, are served packaged meals, mostly takeaways. “All we need is five customers who require packaging for their products,” explains Prasad.

Lean manufacturing process SOPs

Future plans

Entering packaging is one, and getting to the Rs 10-crore turnover is another. The firm has engaged consultants to help it grow.

Aluri says, “We have learned from our mistakes. We do not give credit over a month. Earlier, we used to write off dues as bad debt. But that’s down to nil.”

Aluri blames the printers for the bad debts which arise out of the credit system. “We do not blacklist the defaulters. And the debts keep piling.”

The other way of staying in the black is by working to a margin. “Ideally it should be 20-25% but we work at 13-15%. We don’t take up jobs that don’t fetch us that much.”

Aluri concludes, “If I have to pay my staff, I have to increase my turnover, but more importantly, I need to keep good margins.”

See All

See All