Keetronics: The Peshwas of printed electronics

As the electronics and technology market grows, printed electronics has remained relatively docile. But all that is changing with companies like Pune-based Keetronics.

PrintWeek India was impressed by the highly specialised screen printing set-up. This operation is backed by a young team dominated by women, which, as their managing director, Rajesh Kulkarni puts it, “looks at the world, not as it is but as it could be.”

05 Jun 2015 | By Rushikesh Aravkar

We (Rushikesh Aravkar and Anand Srinivasan) are at Keetronics, where a team dominated by women “is looking at the world, not as it is but as it could be,” as their managing director, Rajesh Kulkarni, puts it.

The company does what it does well – produces functional printed electronics and advanced input devices. In simple terms, Kulkarni explains, printed electronics encompasses printing functional conductive inks on different substrates using different printing technologies.

Gravure is a favourite process with the players who are dealing with printed electronics, says Prof Dr Arved Hubler of Chemnitz University. However, Keetronics has deployed screen printing for the purpose.

Kulkarni says: In India, the applications of printed electronics don’t call for high volumes. The requirement is small quantities with customisation. Hence, screen printing.

A screen printing set-up demands low infrastructural investment and at the same time the investment in executing a job is low, too.

The conductive inks need to be incorporated into very small, confined spaces. This requires precision and hence an in-house screen making set-up with a dedicated dark room.

When we step into their tidy and self-contained workshop, we are told they own five Atma screen printing machines and Natgraph UV drying equipment that can print and cure complex electrical circuits on PET films.

A typical printed electronic job of a membrane keyboard comprises of five to seven impressions.

Vasumati Thopte (l), printing in charge at Keetronics explains the screen printed components a job in progress. These components includedie-electric components, circuits, transistors, resistors etc.

A TWS conveyor IR oven cures the conductive inks on PET films

Grafica's compact machines power the IR and UV drying at Keetronics.

Every piece is then passed through an assembly department, wherein the functionality of each printed piece is checked thoroughly

There are two assembly lines: One for printed circuit boards (PCB) and printed circuit films (PCF).

Majority of Keetronics’ print jobs include membrane keyboards and control panels. A printed circuit film keyboard as thin as one-mm can be produced. Then there are tactile, non tactile and embossed keyboards. All these can find applications where there are control panels.

A multi-up printed circuit film is being checked for registration and embossing

A printed circuit is being crimped to attach connectors on a hand-press crimping machine

Doming for keys allows better feedback when the key is pressed. In some applications, the keys are embossed for better feedback, life and aesthetics

Quality check for effectiveness of a pressed key

The company has an in-house ink matching centre which uses inks from Fujifilm Sericol

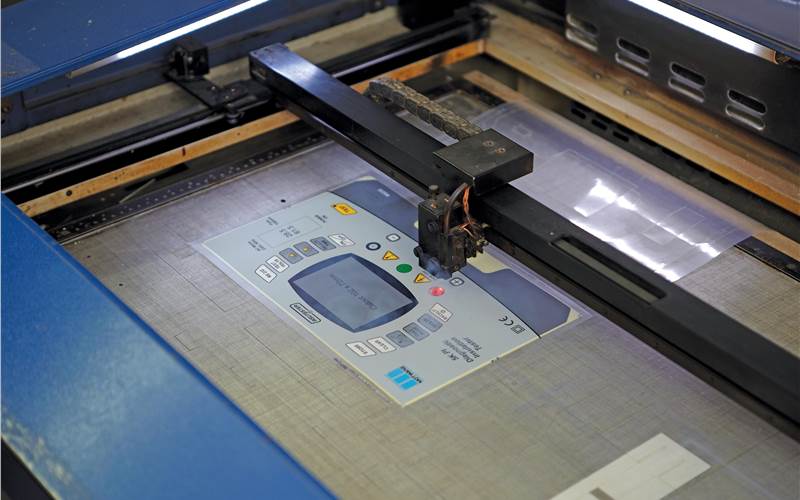

A laser cutting tool allows versatility to design customised shapes

Keetronics has deployed a life cycle testing device from Tricor Systems for fatigue testing of keyboards, keypads, membranes, snap-action switches, and micro switches for fatigue testing

Ultrasonic PCB cleaning

"Keetronics' roster of clients includes big names such as Philips, General Electric, Mitsubishi, Bharat Electronics, L&T and Tata among others," says Snehal Saraf, R&D engineer at Keetronics.

Keetronics has launched Touchmatik brand of switches aimed at both commercial and residential projects.

Touchmatik is easy to specify, install and commission, bringing smart living solutions within reach of small and medium sized projects.

In addition to switching the lights On/Off, controlling the intensity of the light, fan and airconditioner, Touchmatik also provides and cost effective automation to the user on the service front.

'Kee' team behind quality and service.

Keetronics: The Peshwas of printed electronics

See All

See All