The Legend of Autoprint: 10000 installations and still counting

Autoprint commemorated the milestone of 10,000 installations by honouring the proud owner of the humble Dion 450+ machine on 24 April, 2015 during a function in Coimbatore. Autoprint’s highpoint is their reach to more than one-third of the pincodes in India. The 22-year old Autoprint has overcome a tough marketplace and has continued on the development path at its Coimbatore factory.

PrintWeek India looks at how Autoprint has evolved from its nascent stages to become a brand in the prin

08 May 2015 | By PrintWeek India

Autoprint was established on 6 December 1992. Today the manufacturer of offset print and allied machines have three manufacturing factories, two in Coimbatore and one in Himachal Pradesh. Apart from these, there is a customer care centre and head office

Factory being inaugurated in a traditional way. In addition to this manufacturing site, Autoprint has an established demo centre and a 15 year old training setup. The investment for training, with machines, infrastructure and manpower put together, would be approximately Rs 40 lakh

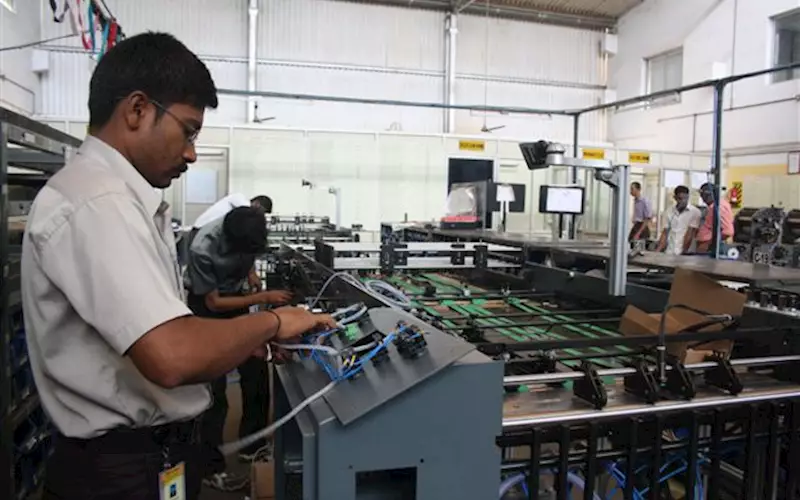

The 1510 and 1520 Colt machines under production. On an average, 50 Colt machines are manufactured in a month

Colt is Autoprint’s most popular product, and has 7000 installations

Vijayshree Instaprint Machinery in Puducherry sought tax benefits. The Puducherry plant was a sales office apart from a manufacturing plant. Then Autoprint shifted this plant to Nalagadh, Himachal Pradesh, when there were issues in tax benefits. The Himachal plant is a manufacturing unit and caters to single-colour press manufacturing

This is Autoprint’s corporate office located in the heart of Coimbatore city where it holds trainings and meetings

Autoprint’s R&D office is spread across an area of five acres with a build up area of 10000 sq/ft. In May 2013, Autoprint got recognition from the Government of India for a weighted deduction of 200% on all capital good expenditure for R&D, other than land

Autoprint’s very recent R&D development is the VDP imaging machine for reading variable data and identifying the image. The image could be a variable barcode. The reading is done by the camera. On verification, you will download a security feature onto the carton thereby making it a unique product

Kaun banega lakhpate scheme conducted for Autoprint buyers held at Ahmedabad by Autoprint and its business associate, Raval Trading

Demo van concept by Autoprint is a first ever initiative by any manufacturer. This was conceptualised in February 2000

The first demo in demo van was of 1510 Colt at Karur

It has an air conditioned environment for the customers to take trials

Since then the demo van has travelled more than two lakh kilometres across the length and breadth of the country for about eight years

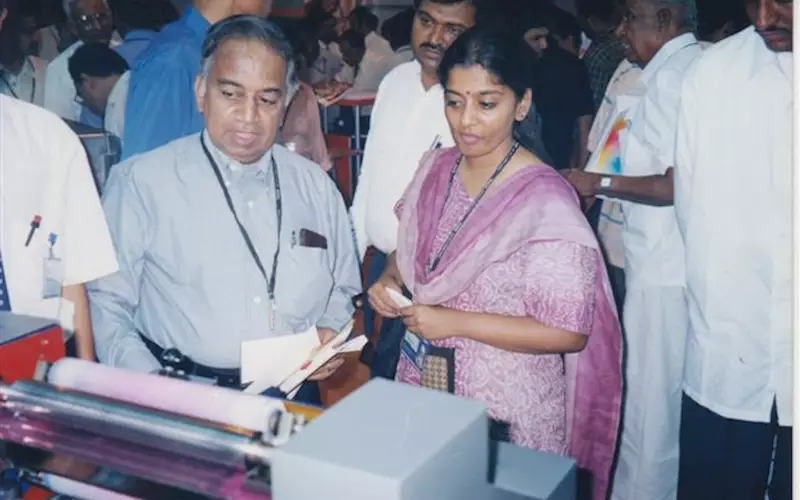

K Ramakrishnan, chairman at Autoprint at an exhibition

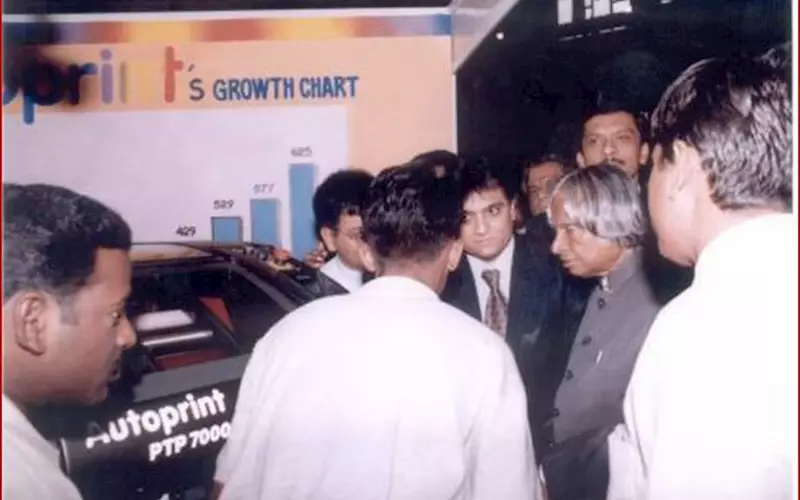

APJ Abdul Kalam, the then president of India visiting Autoprint’s stall at an exhibition held at New Delhi

Ashok, explaining to the Rajasthan chief minister about Autoprint

Autoprint received the prestigious Rajiv Gandhi National Quality Award for the Year 2003 – 2004. Autoprint was ranked No. 1 among 3.4 million small scale industries

UK-based Vaccumatic’s Setmaster ready for dispatch to Sivakasi-based Orient Graphics. Autoprint were the official dealers for Vaccumatic in India

Autoprint’s first CNC machine at the R&D centre. At present Autoprint has six CNC machines

CN Ashok of Autoprint explains the technical specs of the Checkmate 50 print inspection machine to the VIPs from AIFMP

One inspection machine has been operating on a beta site in Bengaluru. One Checkmate is heading for Mumbai. The tech team at Autoprint has been tweaking the efficiency of the machine in the folding carton segment which have been boosted with three Chromasen lenses

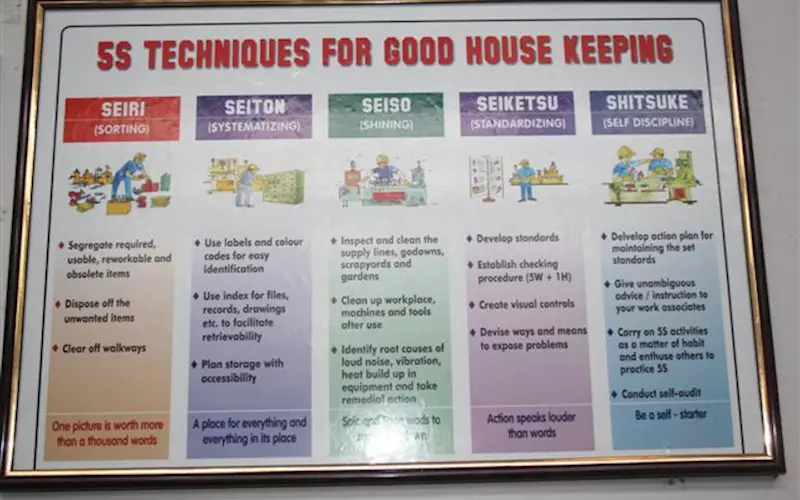

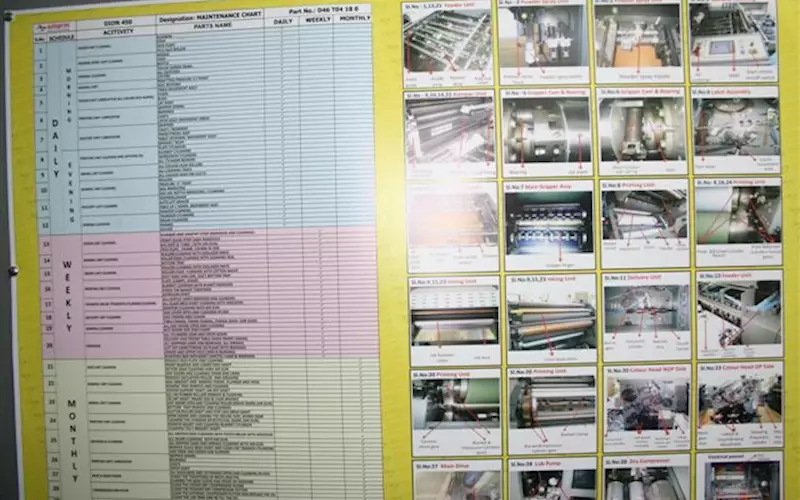

Autoprint follows the 5S principle throughout in the manufacturing processes

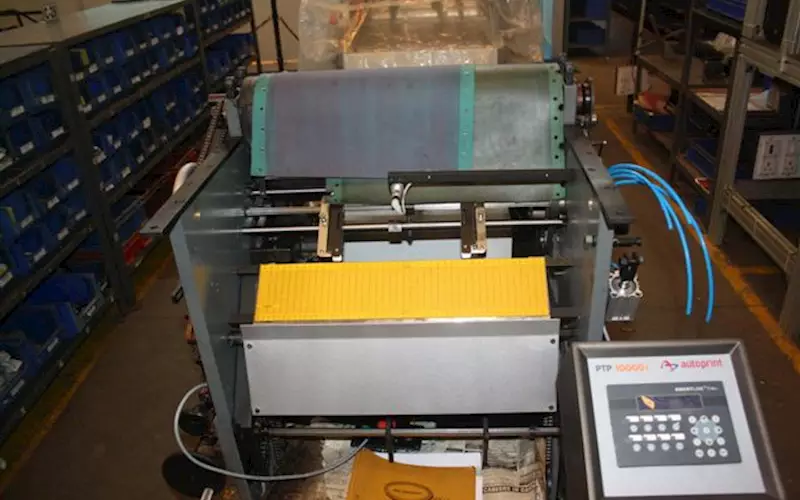

The Dion 450+ four-colour machine being assembled and tested

Two top movers, Fine Coat and Reckoner VDP ready for despatch

Test run for the Fine Coat 65 UV coating machine

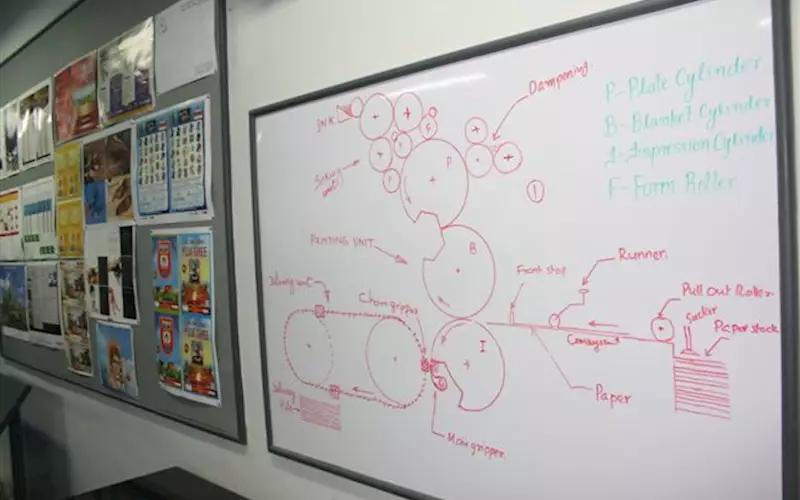

Autoprint follows blue ocean strategy to manufacture machines that could do multiple operations and also reduce the make-ready time

The Reckoner VDP being assembled on the shopfloor

A closer view of the Pack-to-Pack Colt machine

Simple tips on the theory of what the machine does. In addition, Autoprint's video tutorial helps in better understanding of settings and paper handling

Spot the errors and then do prevention and remedy

The Autoprint demo centre in Coimbatore where a single skilled operates the Dion 450

The thumb rule to top quality printing: simple tools and to keep the shopfloor as clean as "a temple at home"

Autoprint does prototyping and R&D with the help of the Solid Edge software. This helps Autoprint identify if a mechanism is working properly. Apart from this, the entire bill of materials is available. Also, the Autoprint team can check on the critical parts

On behalf of Usman Khan of Jivandeep in Lakhimpur-Kehri, the proud owner of the 10000th Autoprint machine, Autoprint’s dealer in UP receives the honour

See All

See All