Picture Gallery: Open House in Kerala celebrates print power

The second in the series of open houses, jointly organised by Henkel and Welbound, was held on 20 July, with an objective to review the dynamics of bookbinding and publishing industry. The event saw over 30 book print firms and publishers mark their attendance at Welbound’s Thiruvananthapuram plant in Kerala.

The open house included factory visit, live demonstrations and knowledge sessions.

PrintWeek India's highlights from the open house...

26 Jul 2013 | By PrintWeek India

Picture Gallery: Open House in Kerala celebrates print power

The Welbound team welcomes the guests at Welbound's Thiruvananthapuram factory

The open house commences with a walk through glimpse of the Welbound factory. P Sajith (r), marketing director, Welbound Worldwide: “The fast changing scenario in book production for long as well as short runs has made it imperative for the book printers to evolve and up the ante to add value to the printed books"

The Welbound factory is fully loaded with CNC part forming machines

The different tool heads for CNC machines that produce critical machine parts, some of these parts are used by ISRO for metallurgical development of rockets

The machine parts are exposed to natural weathering to relieve the stresses induced during manufacturing. This process continues for for 30-60 days

Welbound's Kishore Kumar explains manufacturing process citing the engineering drawings of machine parts

The sample spare parts arranged for display

After the factory visit, the participants visited a book printing firm located 100 metres from the factory. Here, they observe Welbound's WB 3600 12 clamp perfect binder in action

The printing firm houses a range of Welbound products which produce textbooks for Kerala, Karnataka and Tamil Nadu textbook society. In picture is Diploma 4Z3X combination folding machine with four buckles and three knives

In the post-lunch session, the participants interact with Henkel’s Ashish Pradhan and Pearson’s Subhasis Ganguli

Pradhan in his presentation discusses challenges for the Indian print industry and highlights the best practices to be adopted to overcome these challenges

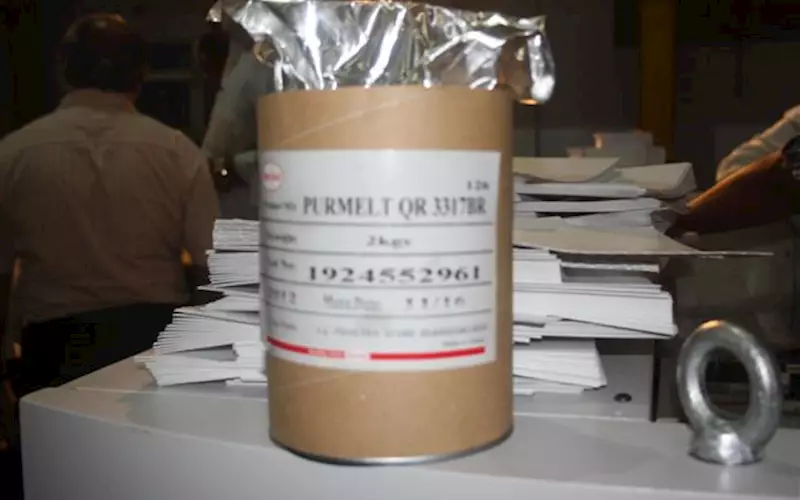

In a Q&A session, Henkel’s Sandeep Pai(r) said, “The short-run market such as photobook has been a quick adopter of PUR bookbinding technology.

Suresh Nair of Welbound explains the strengths of PUR-binding with a "well-bound" book sample

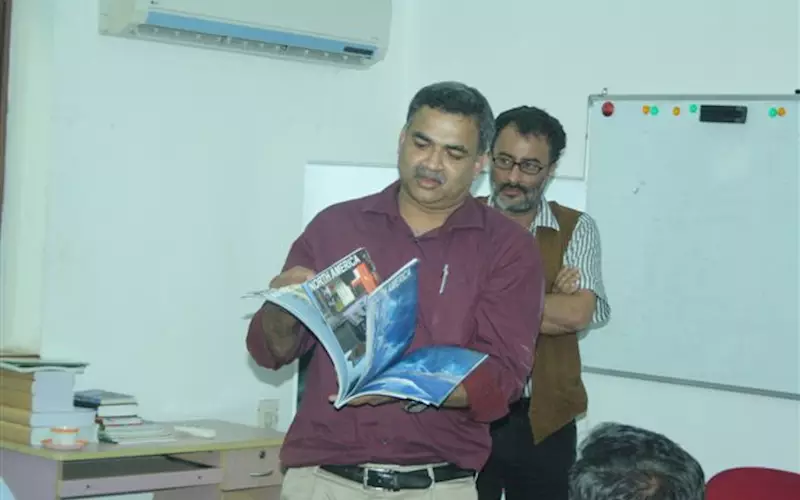

The highlight of the open house was an interaction between Subhasis Ganguli of Pearson and Ramu Ramanathan of PrintWeek India. Ganguli (r): "Faster turn-around times, health and safety norms, capacity and storage space to deliver just in time etc are some of the things we expect from our printers"

Ganguli pointed out each stage of the book process is linked with the others. Sawing the skill set apart means each job will be done worse. Therefore he said, every book print firm must have 3d P&L instead of charging per 1,000 books

Welbound's Kishore Kumar (r) demystifies PUR for Ganesh Sivam of 1st Print

K C Sanjeev of Welbound in discussion with top print CEOs about effectiveness of binding required for printed books

Sandeep Pai and Ashish Pradhan of Henkel discuss the opportunities in the Indian book printing segment

A WB 3600 - 12 clamp binder specially designed for cover pasting and side stitched books using 'water-based adhesive', attracted some of the textbook printers present in the group

The folding machine from Welbound's technology partner GUK was showcased at the open house

The high-end electronics of the Welbond's single clamp perfect binding machine keeps its hassle free from fluctuating electric supply

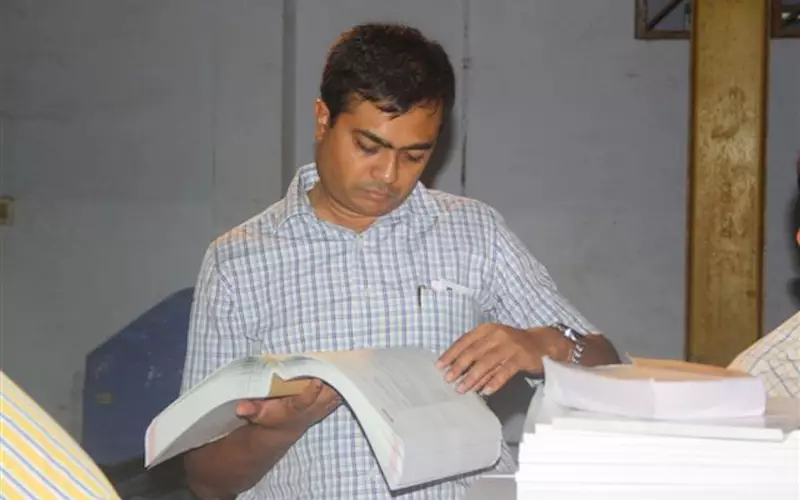

Mandar Ugar of Pune-based Vikram Printers scrutinises the lay flatness of a PUR-bound book sample

Kishore Kumar of Welbound discusses the nitty-gritties of binding with Ashish Pradhan of Henkel

According to Henkel, after the initial struggle, it now sees that printers are realising the benefits of using PUR in terms of cost and time savings

Welbound's Suresh Nair in a tech-talk with book printers

Stitchwel Colt, the modular saddle stitcher is ideal entry level saddle stitching system to produce superior quality centre stitched books

The yet to be launched seven clamp perfect binding machine was being redied for demonstration

Welbound feels that the open house is a platform for book publishers, printers, binders and short-run print solution providers to discuss trends and opportunities in the field

In conclusion, when corporations and institutions like Welbound and Henkel come together, then a network could be created; and there can be an additional value to the books we produce

See All

See All