Producing Top Books – The Replika Way

The best endorsement for Replika Press comes from a customer, Neil Bradford of Random House in London, who says, "I have dealt with Replika for many years now and they have always been a committed, positive and professional organisation very much setting the standards for book production and service within India."

A guide to the book production process at its Kundli unit.

Photographs: Rahul Kumar

Words: Rahul Kumar and Supreeth Sudhakaran

19 Jul 2013 | By PrintWeek India

Producing Top Books – The Replika Way

Replika Press' efforts to produce top notch books makes it one of the best book print firms in the country

In 2010, the company achieved a turnover of Rs 70-cr (Rs 700-million). Seth: "Notwithstanding the slowdown in 2009, exports rose by 15%."

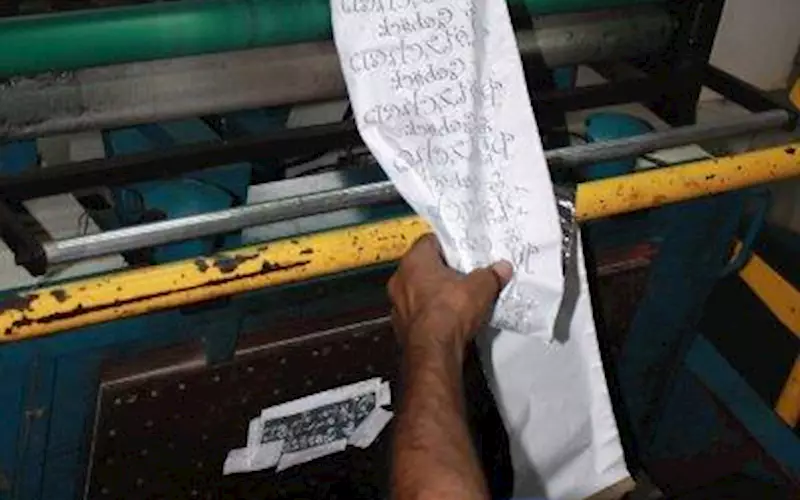

The first and foremost step in book production is typesetting

This happens in three stages: typesetting, checking for font size and other formatting details and finally, making corrections, if any

Once the pages are finalised, the CTP operator readies the plates for printing

In the pressroom, the operator prepares the sheets to be printed. This is in keping with Replika's adherence to ISO 9001:2008, FSC, SMETA/Prelims and BSCI social audit accredited, SAP ERP systems

At Replika, a Protek processor is used to expose the CTP plate. This is punched and delivered to the shopfloor where the printing press is located

Printable cut-sheets are loaded to the feeder of the press

A printing press operator mounts the CTP plate on the press

The press at Replika is equipped with an auto-plate loader

Once the paper and plates are loaded on the KBA Rapida 105 (U) eight-colour press or the Heidelberg press, the printing process begins

The press operator monitoring the supply of sheets from feeder to the printing unit

The operator checks the first few sheets for printing quality and registration faults

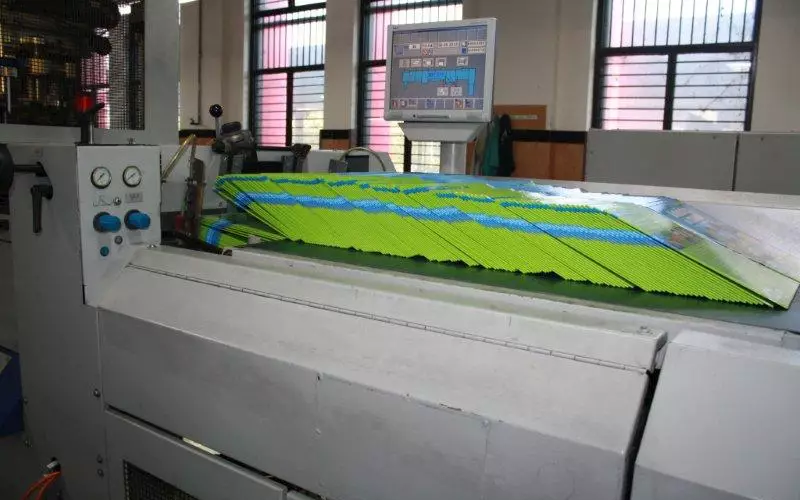

The printed sheets are then put on the folding machine

The folding machine operator collects the press signatures

Gathered sections on its way towards becoming a final book

Section-sewn books ready to be trimmed to the final cut size

Section-sewing operator examining the stitched sections

Section-sewing operator puts the sections of sheets into the machine

A stack of soft bound books; ready to be packed in boxes

A stack of hard case books minus outer jacket

The covers being prepared and inspected by inspectors to ensure high levels of quality

Samples of hardbound covers at the unit

The prepared hard covers are loaded on the case-making machine

A fully-bound hard case book on the Kolbus machine at the unit. The machine can produce sewn books at the speed of 70 books per minute from a minimum size of 90x100x3 mm to a maximum of 320x510x80mm

Replika invested in a Kolbus Sigloch SB-7020 and a book-block preparation line Kolbus BF 527 to upgrade its hard casing-in online in 2012

Hard-case books on a conveyor belt and shrink-wrapped

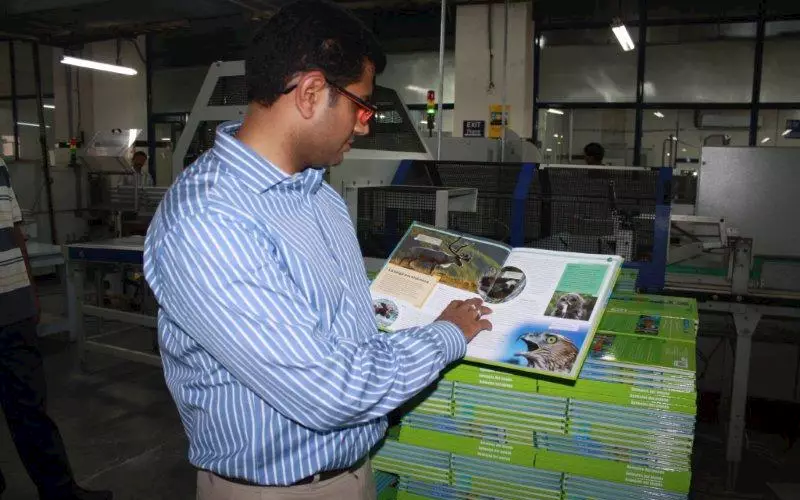

Sanandan Seth, director marketing, Replika Press, personally, checks the finishing of the book

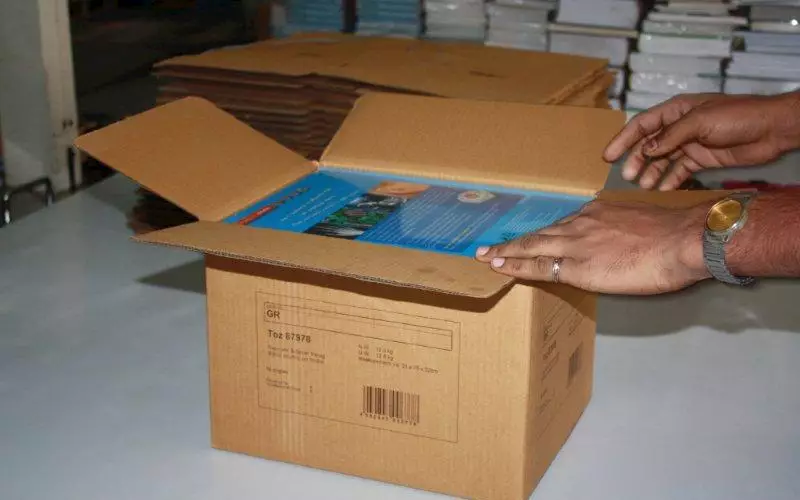

The books are packed using tapes and filled in corrugated boxes before they are loaded for palletisation process

A corrugated box with books that are ready for being handed over to the logistics department and palletisation process

A stack of packed corrugated boxes are ready to be loaded and shipped. Replika has a capacity to produce 1,15,000 books per day

Once the books are packed in corrugated boxes after being sealed, each box is strap-packed

Systematic palletisation is the key to avoid bottlenecks at delivery. Optimum packaging is necessary to keep the books moisture-free during transportation

Bhuvnesh Seth, managing director, Replika Press: Innovation tends to follow a fixed path - one big idea begets another

Replika Press receiving the Post-press Company of the Year accolade at the PrintWeek India Award 2012. Will they repeat history ?

See All

See All