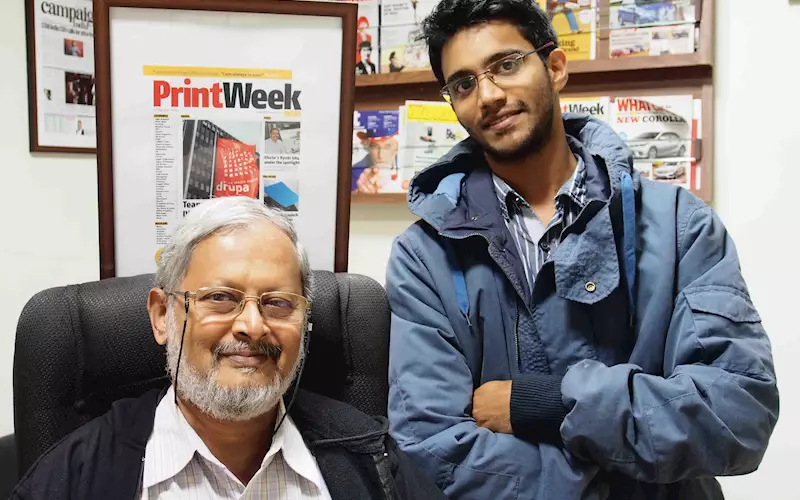

Anand and Sanjeev’s helpline

Sanjeev Govekar, the production manager of Haymarket India and Anand Srinivasan, senior correspondent at PrintWeek India track down simple solutions to your technical troubles.

15 Dec 2014 | By Anand Srinivasan

What are the different process used in textile printing? And which would be the economical process for smaller runs?

Textile printing uses two prominent techniques, direct to garment printing (DTG)- it is either printed by screen or digital and heat transfer printing, the transfers for which can be produced digitally or by a combination of screen and offset. In terms of price, currently screen printing rules the DTG printing /garment decoration due to the advantages and disadvantages in digital print. Govekar sir and I would say digital is 8-10 times costlier than screen print. As per our calculation, if a screen printing costs about Rs.15-30 per piece, the same would be about Rs 120-150 per piece when we print on digital. Digital printing is good for short run of about 200-300 pieces. Again, it depends on customer, market requirement, quantity, price, and delivery schedule. But most customers want screen printed stuff.

What are the circumstances under which I should prefer PUR binding over hotmelt binding. Does PUR binding allow you to bind smaller pagination documents?

PUR binding can be used in perfect bound applications where Ethylene Vinyl Acetate (EVA) and other traditional adhesives may not be well-suited.Some instances include books which require frequent usage, books that would be subjected to extreme temperatures and books that have glossy pages.

Also, PUR can be used for books with relatively few pages where the recommended spine width can be as narrow as 1/8 inches and that for perfect bound is 1/4 inches. This is because PUR adhesive does not need as much surface area to firmly secure the book’s pages.

See All

See All