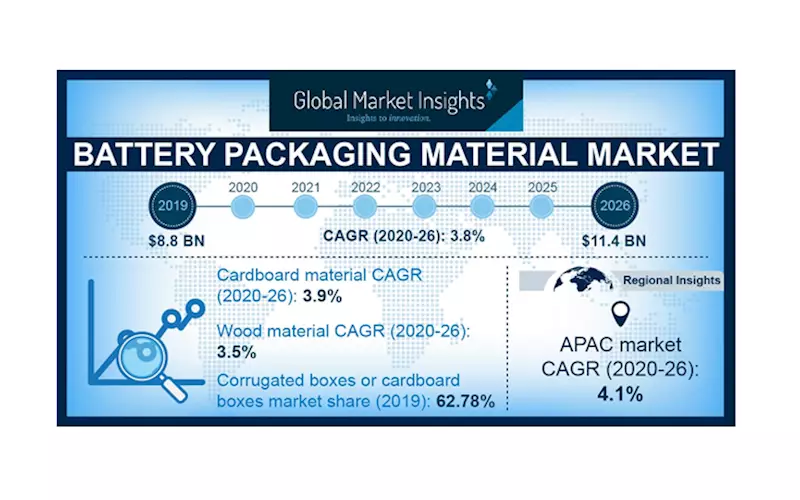

Battery packaging material market size to surpass USD 11.3-billion by 2026

According to a new research report by Global Market Insights, battery packaging material market size will surpass USD 11.3-billion 2026. Battery packaging materials have been playing an invaluable role in the battery manufacturing process. Even though demand has been fuelled by the automotive sector, cell phones and portable computers, applications such as electric vehicles (EVs), are also gaining traction.

04 May 2020 | By Dibyajyoti Sarma

Of late, there has been demand for low-emission and emission-free energy sources, including renewables. Notably, popularity of Li-ion batteries has surged for portable devices, EVs and other electronic applications given that they have high energy density, high voltage, and light weight.

Industry players have exhibited profound traction towards lithium batteries which have become the top-notch energy source to bolster a range of consumer goods, including cars, EVs, and mobile phones.

Drawing on the potency of lithium batteries, packaging designs and the combination in battery packs and modules are being offered in massive quantities.

With millions of EVs already on the road, the desire to decrease the repercussions linked with the use of internal combustion engines fuelled transportation and the trend to reduce carbon emissions has surged in recent years.

Factors such as high voltage, high energy density, low self-discharge rate, long life cycle have brought a paradigm shift in EV industry and revolutionised battery packaging material market.

Increased focus of the US Department of Energy (DOE) on lithium-ion based electrochemical energy storage owing to the theoretical capacity and electrochemical potentials will augment its demand. Battery packaging materials have been leading to cost savings, on the heels of seal-strength properties, mechanical, and permeation properties. With the deployment of batteries to bolster an array of applications soaring by leaps and bounds, there are opportunities up for grabs for stakeholders.

It is anticipated that end-users are likely to be inclined towards PVC plastic as it has been perceived as an affordable material and offers tremendous solder and abrasion resistance.

APAC region is likely to be the happy hunting ground as electronics industry appears to thrive in countries such as India, China and Japan. Japan, along with developing Asian countries may offer unparalleled opportunities to stakeholders eyeing to expand their penetration.

For details visit the Global Market Insights website.

See All

See All