Bobst rolls out new machines focussed on brand owners challenges

Brand owners, small or large, are under pressure from local and global competitors and changing market expectations. They face many challenges, like shorter time-to-market, smaller lot sizes and the need to build consistency between physical and online sales.

09 Jun 2020 | By Noel D'Cunha

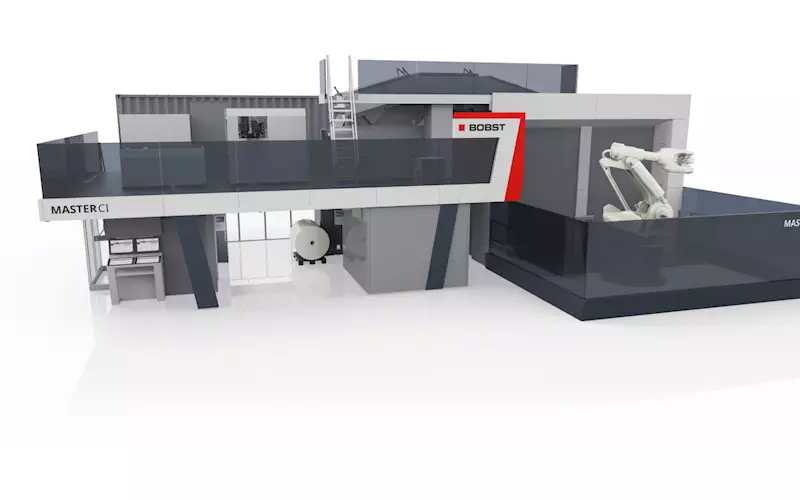

In a Skype-hosted virtual conference on 9 June 2020, which replaced its Drupa participation, Jean-Pascal Bobst, CEO, Bobst Group announced the launch of new converting machines and tools - a new CI flexo press, a laminator and inspection systems among others.

At the heart the offerings if the Bobst Connect concept, an open architecture cloud-based platform delivering solutions for pre-press, production, process optimisation, maintenance and market access. “It ensures an efficient dataflow between the digital and physical worlds. It will orchestrate the entire production process from the client’s PDF to the finished products,” said Bobst.

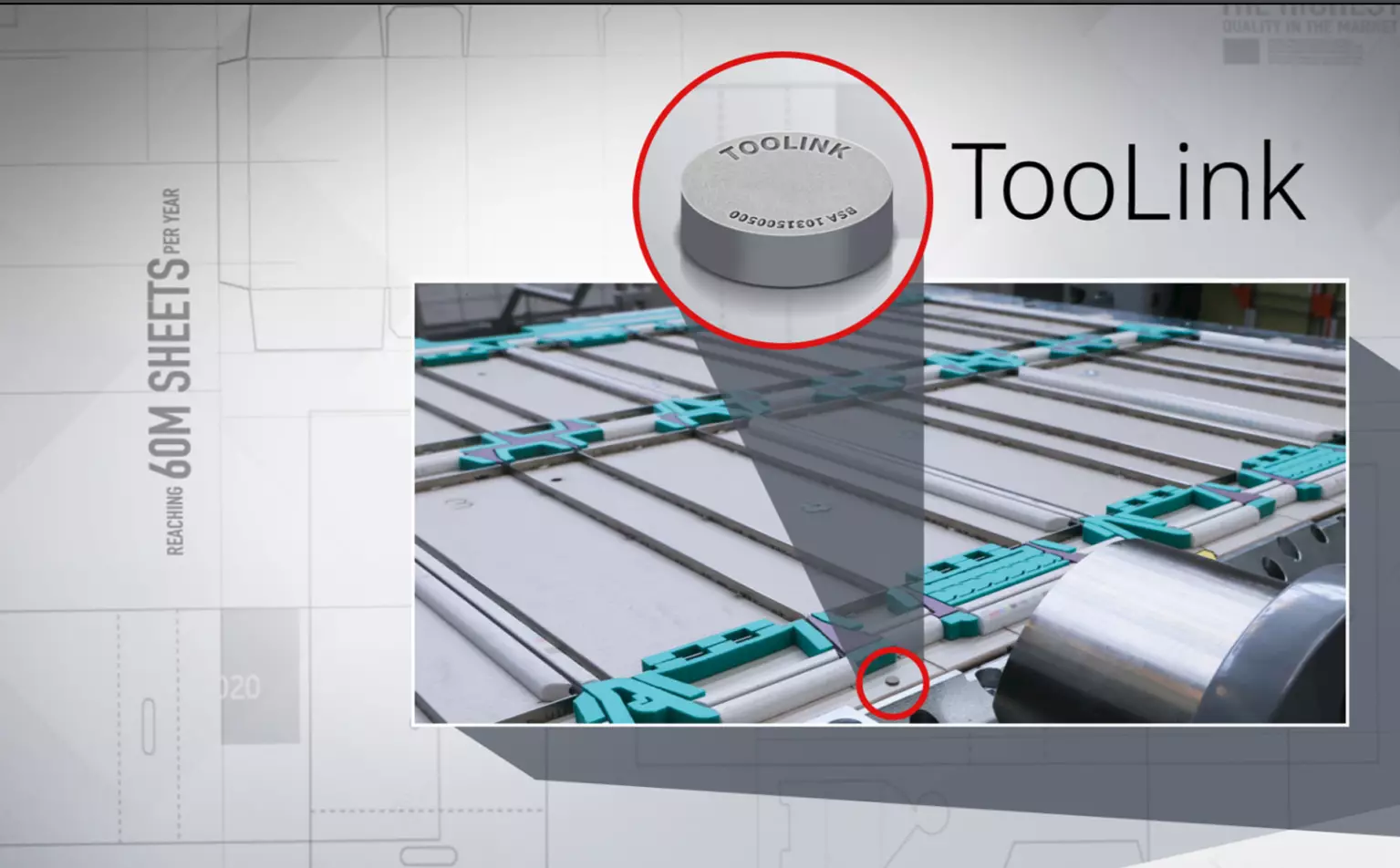

The new kits include the Mastercut 106 PER, TooLink Connected Tooling for die-cutters, new Accucheck, and a new Masterstar sheet-to-sheet laminator for the folding carton industry; the new Master CI flexo press, new multi-technology Nova D 800 Laminator, the Master M6 inline flexo press equipped with Ink-on-Demand (IoD) and DigiColor inking and colour control for flexible packaging industry; OneECG, Bobst’s extended and colour gamut technology; and new large-format version of the Digital Inspection Table (DIT).

Bobst said, the current packaging value chain remains very fragmented where every phase in the process is isolated into silos. “The new requirements require all key players to have an end-to-end view. Take, for example, the Master CI press – it takes 60-secs to change the job, reduction in waste with water-based ink, 100% quality control from PDF to finished products. It’s the same across other machines.”

The new Master CI is a six-colour press which combines smart technologies like Smart GPS and advanced automation to make the press operation easy and fast. The press can produce up to 22-million stand up pouches in 24 hours with one operator or 7,000 jobs per year. It features the Job Recipe Management (JRM) System for a digitalised production workflow from file to finished product with the creation of a digital twin of the produced reels.

A new tooling assistance from Bobst is the TooLink Connected Tooling for die-cutters. The new kit, Bobst said, can save up to 15 minutes per job changeover and simplifies the interaction between converters and the die-makers.

“In the current situation, automation and connectivity are more important than ever, and greater digitalisation is helping to drive these,” said Bobst. “Meanwhile, achieving greater sustainability is arguably the single most important current goal in all manufacturing. By uniting all of these elements in our products and solutions, we are shaping the future of the packaging world.”

See All

See All