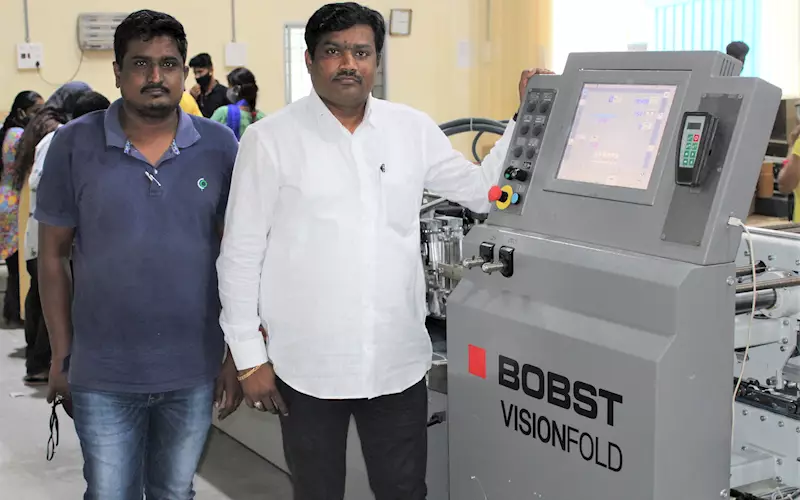

CPP gives converting a Bobst Visionfold push

Hyderabad-based Creative Print & Pack (CPP) installed a Bobst Visionfold 110 A2 folder-gluer to its finishing department in 2019 in a bid to help its customers’ demand for just-in-time (JIT) delivery.

07 Sep 2020 | By Noel D'Cunha

“We now understand how much a disaster can the disrupt supply chain,” said CEO of CPP Kondaiah Chowdary. “However, even in normal times, it was necessary for us to form a strong partnership with our customers to ensure that there’s no break in the process of the efficient delivery system of their products to the market.”

Established in 2007, CPP specialises in producing hand tags, mono cartons, corrugated and rigid boxes, canisters, and paper bags for customers in the FMCG, textiles, cosmetic, electronics and pharmaceutical sectors across South East Asia.

The company operates from two manufacturing units in Hyderabad and in the last few years has invested in a pre-owned six-colour Heidelberg press and a Heidelberg Easy Matrix die-cutting machine to boost its production capacity. “We understand that without an agile supplier, our customers who demand JIT deliveries could face higher-priced goods. It could perhaps wipe out any cost savings achieved through reduced inventory,” explained Chowdary.

“The main challenge before we invested in the Bobst Visionfold was the output, changeover times and capability to process different types of jobs. We had Boxtech folder-gluer and they had their own limitations and we needed to grow our business. With the Visionfold 110 A2 we could open up new business opportunities, increase our output and deliver faster output to our end buyers with added advantage of improving our cost efficiency,” said Chowdary.

The new Bobst kit, Chowdary said, lets his company be more flexible allowing short runs, quick set-ups as well as meeting any spike in demand. “We follow JIT delivery, but if there’s a sudden surge in demand, we have to be prepared to meet it. Here, speed was a major deciding factor. We also needed to extend our capacity and eventually succeeded in doing so by adding the Bobst Visionfold 110 A2 folder-gluer.”

The Bobst Visionfold is capable of running at a speed of up to 350 m/min, manufacturing both side-pasting boxes and lock-bottom cartons, three-ply corrugated cartons and with options for 4/6 corner and specialty boxes.

“The know-how and process support of Bobst to run difficult jobs, which comes with experience, has helped us run the machines smoothly, allowing our company to be able to dispatch goods on-time thus, boosting our productivity in the long run,” said Chowdary.

Besides the capabilities of the Bobst kit and the range of its machines, it’s the reputation of Bobst’s support team to take on the responsibility of after-sales which was crucial in making the buying decision. “We chose the Visionfold after duly researching the market,” said Chowdary. “The best part is that during this first year with the Visionfold, we have not faced any issues,” he concluded.

Creative Print & Pack fact file

- Established in 2007

- Location Two units in Hyderabad

- Speciality Packaging (producing hand tags, mono cartons, corrugated and rigid boxes, canisters, and paper bags)

- Equipment Heidelberg six-colour press and Easy Matrix die-cutter and Bobst Visionfold 110 A2 folder-gluer among others

See All

See All