Investment strategy on target at Concord

Vadodara-based Concord Printing (Pravin Printing) has installed an RMGT 920 six-colour plus coater press with six-cassette AMS P3 UV curing system and Bobst Visionfold 110 folder-gluer recently, as part of a long-term investment strategy.

16 Jan 2017 | By Rushikesh Aravkar

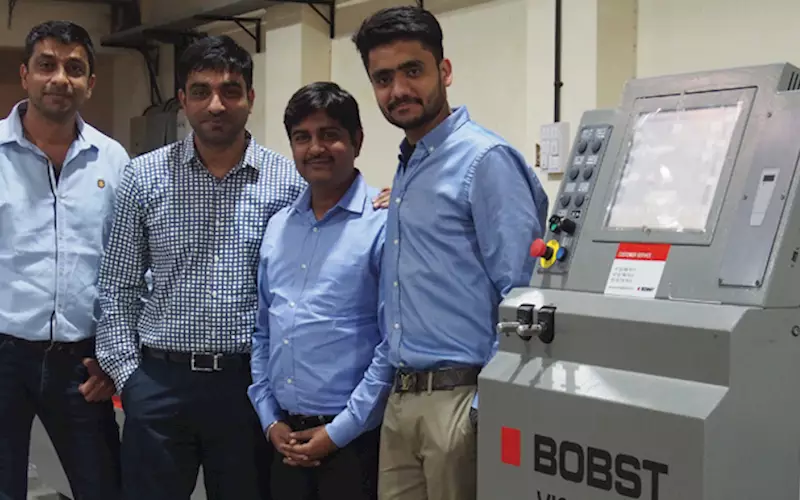

The 60-year old commercial printing business, headed by Memon brothers – Kayyum and Arshad – is slowly and steadily transforming itself to become a packaging converter.

The RMGT 920 press is Concord’s first UV printing machine and will enable it to produce metallised cartons.

Kayyum, director at Concord, said, “The 25x36-inch size is an advantage. All our ancillary equipment are suited for this size and almost 80% of commercial and packaging jobs are covered.”

In the post-press division, Concord already has a Maxima die-cutter. The new Visionfold 110 folder-gluer will enable it to take on complex four- and six-corner gluing work.

Arshad said, “Having the latest technology gives a competitive edge. Visionfold with four and six corner attachment gives us versatile work mix. It gives us the ability to quickly and easily process four- and six-point corner work, including complex boxes and trays that would compromise the efficiency of most folder-gluers.”

With the new investments, Concord has been able to convert a majority of its existing non-UV jobs to UV and also add several new clients thanks to higher levels of operational efficiency.

“The new machines are fully-loaded, so we are able to dispatch printed and converted products within two days. The Visionfold speeds up the make-ready and guaranteeing consistent output quality. Also our experience with the service levels from Bobst is what customers expect from a supplier,” added Memon.

Operating from a 22,000 sq/ft plant, Concord converts 80 tonnes of FBB per month.

See All

See All