Labelexpo Europe 2019: Luster introduces LabelRoll-F inspection system with an industry first 8k resolution inspection camera

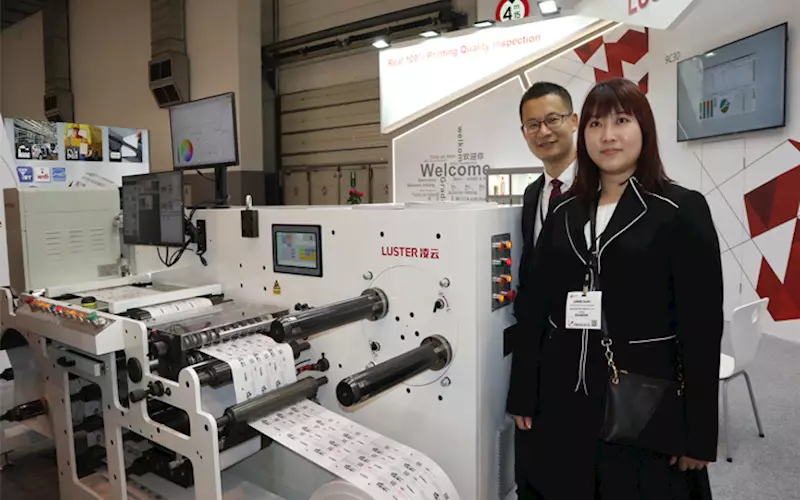

The China-based inspection system specialist is showcasing two of its key products – LabelRoll-F and PrintingProof inspection systems.

27 Sep 2019 | By Noel D'Cunha

The PrintingProof, a pre-press tool that effectively compares the digital files sent by the brands with the one produced by the converter or the signature file to the converters printed sample. The software compares and detect graphics errors, print errors, spelling errors, Braille checks and translations, text errors, barcode verification etc. “All differences are highlighted within seconds, ensure the pre-press works are finished error-free. I think it'll be very helpful for them to save costs of rejection,” said Carrie Dual of Luster while speaking to PrintWeek India.

The second product is the LabelRoll-F, a 100% inspection system which allows checking of irregularities from the beginning, and even during print, if its inline with the printing press.

Duan claimed that it is one of the most powerful optical system for 100% stable inspection on common paper, film, holographic/metallic/high-

The LabelRoll-F is also equipped with a brand new colour measurement and management solutions to complement the 8K resolution camera. “The new feature has the ability to calculate the LAB value and the delta e value and give the customers a very clear visual, especially supervisors who can check if the values are above or under the standard line they have to work with. It also has a colour spectrum, which enables the operator to check the levels of different colours being printed,” said Duan.

For Luster this will be its third appearance at the Labelexpo Europe show. Carry Duan of Luster said, the first two were standard booths, and aimed to see how the market is like, a bit about the competitors and how will our product work. I think, this show can be considered as the official debut of Luster.”

Luster has about 2,200 inspection systems in different segments of packaging installed worldwide, of which 90 units are installed outside China. There are 10 inspection systems installed in India.

According to Duan, Chinese products are becoming more and more acceptable across the world. “I think China has gone through three stages. The first was where China was the world manufacturing centre, where you saw every brand set up shop. The second stage was where the Chinese companies replicated the technologies. But the last 10 years has seen China go through a very high-speed development stage, where it has produced innovative products, added new features.”

See All

See All