Medpack boosts die-cutting ops with Vinsak E-Diffsystem

Hyderabad-based pharmaceutical packaging start-up Medpack India has reinforced its die-cutting operations with the installation of Vinsak E-Diffsystem on its Lombardi Synchroline (330-mm) narrow-web press.

22 Jun 2021 | By Abhishek Muralidharan

The system is powered by Spain-based converting equipment manufacturer Technocut, which recently joined hands with Vinsak in August 2020.

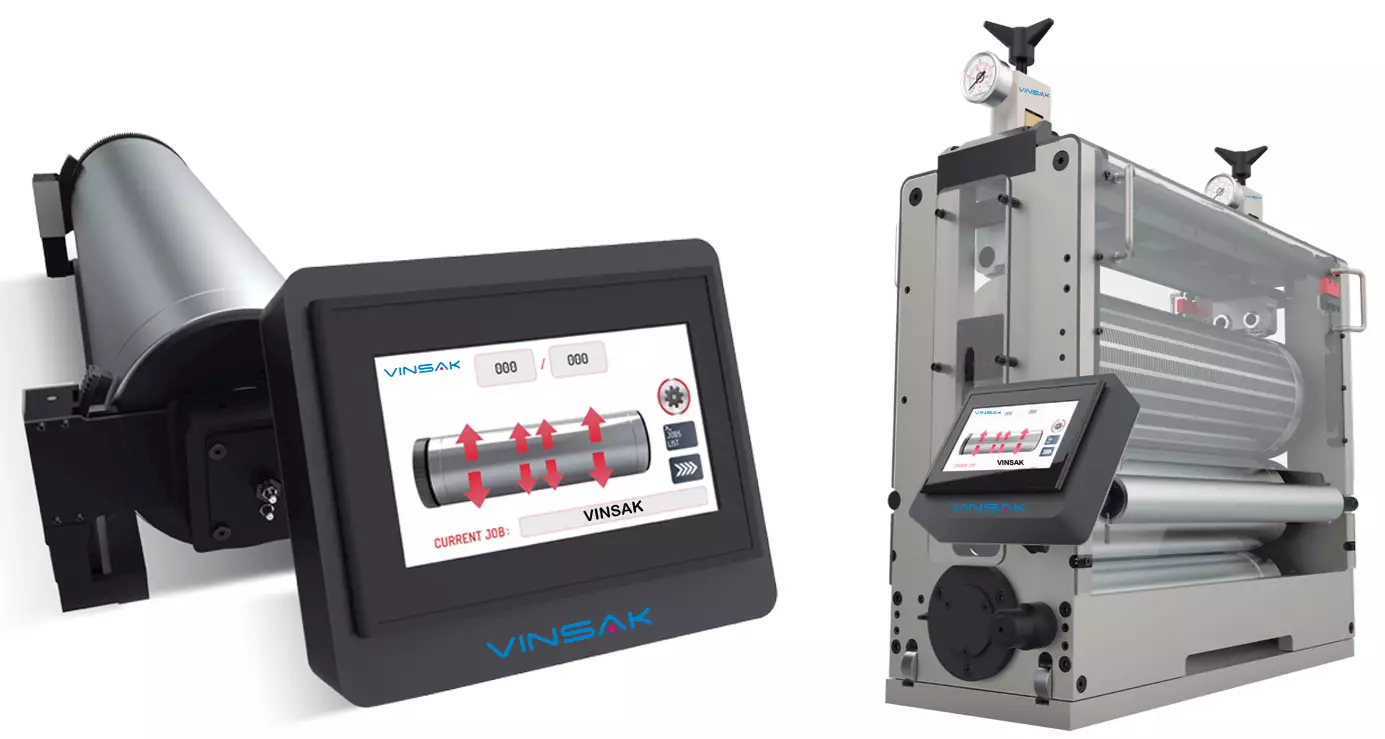

The E-Diffysystem is a unique air gap system designed to control the die-cutting process in narrow-web label production. “This new system will help us offer cutting-edge functional products to the pharmaceutical industry,” said T Muralidhar, director, Medpack India.

According to Harshad More, national head service, Vinsak India, equipment such as the Technocut E-Diffsystem can help label printers enhance print quality, reduce production cost and save time and wastages. “The system ensures smooth label dispensing on high-speed lines by eliminating problems such as a deep die-cut or marks on the release paper among other solutions,” he said.

One key aspect about the equipment is its ease of installation - the system can be simply installed by replacing the existing anvil roller in the die-cutting station enabling a flexible die to be cut into pressure-sensitive materials virtually independent of the liner thickness.

The system facilitates an electronic variable adjustment with micrometric precision in the correction range of + and - 0.001-mm between the anvil roll and the magnetic cylinder. “E-Diffsystem is capable of electronically changing the air gap between the roller and cylinder in three different ways – operating, driving side and overall adjustment,” said a press note shared with PrintWeek.

It added, “The E-Diffsystem is miles ahead in technology. The product distinguishes itself from other mechanical systems in the market as it eliminates the need for regular adjustments and lubrication along with a lower step size.”

The E-Diffsystem advantage at a glance

- A clear human-machine interface

- An initialisation function to automatically return to starting job position

- Store settings as per each job (as a reference position)

- Automatic maintenance signals (greasing)

See All

See All