Perfect binding week from Impel-Bindwel

In 2023, the Impel-Bindwel group will complete three decades of its presence in India. To celebrate this spirit of service, the 30th year will be celebrated with a perfect binding free-service week which will kick-off on 2 October, Gandhi Jayanti. For this Impel-Bindwel team has selected key regions in the country, for example East Delhi, Central Mumbai and so on.

21 Sep 2022 | By Charmiane Alexander

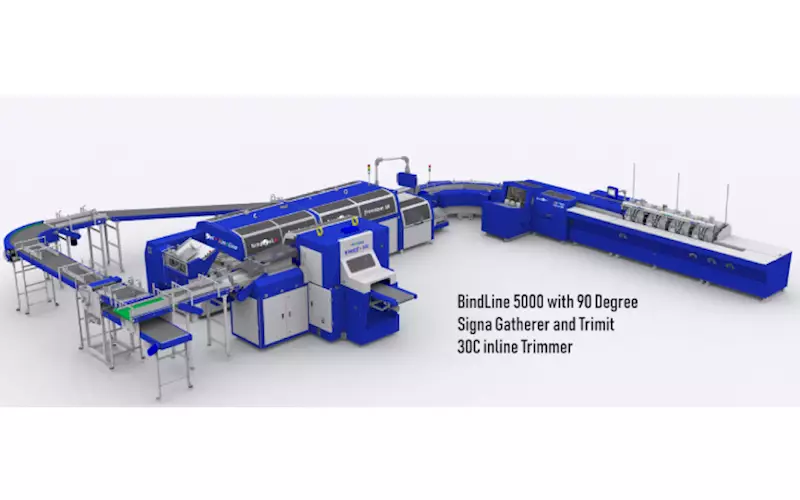

With a modest beginning as a service provider to the book print industry, the Impel-Bindwel went on to become the largest supplier of bookbinding adhesives and later, manufacturing automatic book binding machines. Connectivity, shop floor space optimisation and being operator friendly have been the key themes for the organisation’s growth in innovation. The latest inline binding solution from Bindwel which was on display at PrintPack 2022 has the smallest footprint among machines globally, while delivering the lowest costs of energy per book.

There will be many new alliances, segments, products and services planned and will begin in the 30th year. The origin of the Impel-Bindwel group has been in service. “Every customer we have serviced has made us richer with a technical insight and added to our ideas on serving customers better, said Pallippuram Sajith. the managing director of Impel Services (A Welbound group company).

Top engineers from the Impel-Bindwel team have selected specific regions in the country, for example East Delhi, Central Mumbai and so on. The group led by Arvind Kalasur, Gopakumar and Jose Vaidynathan will visit book print customers at a pre-fixed time and audit their perfect binding machines. Also, they will provide tips on how to maintain binding machines better as well as also guide customers about controlling wastages.

Arvind Kalassur, the director of services for the Impel-Bindwel group said, "We have been doing this as a part of our maintenance contract or as adhesive support, to many customers. We have seen that we can help the customers improve their quality, reduce costs and eliminate wastage." Kalassur added, "The issues in bookbinding are either due to material, machine or manpower. Through this free service week we are trying to address the issues faced by customers who have aged machines. It is not important whether it is a machine supplied by us or not, we feel enthused to support any machine of every binder who has been with us in our journey of 30 years . Also we will be able to help them with spare parts at cost prices from the market."

"The glue pot of a perfect binder is where all the trouble begins. Pigmented adhesives, with fillers as well as foreign particles get deposited on the tank, layer after layer. This will ensure that the heat is not transferred to the adhesive as planned, and clubbed with high speed production of thick books, in most times it leads to what is called "cold-binding" which not only consumes more adhesives, but ends up giving reduced bond strength said Gopakumar Kandoth, the national service head for the group. Kandoth added, "Then comes the milling station which is a "dust-generator" and if not extracted properly, along with the open glue pot leads to a lot of trouble like charring. We will help these customers to understand such practical insights, keep their operational costs in check and provide more life for their machines – as we work with them to resolve some of these critical issues", said Kandoth.

"The Impel-Bindwel team will be calling up the customers in the designated areas and fixing up the dates for this free services program. Our teams are eager to reconnect with our customers and serve them with all their energies during the Perfect Binding Free-Service Week, the team from Bindwel will help book print firms bind books better and more cost effectively", said Anil Kumar, director sales with Impel-Bindwel group.

Today, the Impel-Bindwel has ventured into manufacture of case packaging machines that has leading brands like Nestle, Haldiram's and ITC as customers. The group also boasts of 30 years of relationship as a leading distributor partner of Henkel Adhesives in India, and is associated with Nordson group for integrating their adhesive dispensing technologies. They also represent Wohlenberg- Baumann group as well as the world leaders in pharmaceutical leaflet folding machines Guk-Vijuk.

The 150 plus people company is headquartered in Mumbai and manufacturing facilities in Bengaluru.

See All

See All