Printwell installs Amritsar’s first Heidelberg Speedmaster SX74

Amritsar-based Printwell has recently installed the Heidelberg Speedmaster SX74 four-colour press, becoming the first firm in the city to do so. A commercial printer, Printwell specialises in books, catalogues and brochures. The investment is a part of the company’s strategy to create new growth platforms.

15 Nov 2018 | By Rahul Kumar

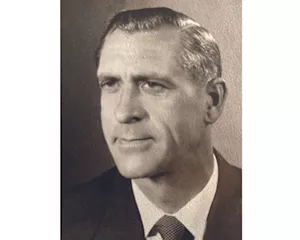

“Associating with a world-class brand like Heidelberg is a key milestone in achieving our long-term vision. With this unique investment in innovation and productivity, we are confident of a step change in our future earnings power,” Gurinder Singh, managing director of Printwell, said.

Established in 1994 to bring international standards to regional publication, Printwell has taken huge strides forward in its mission. From using pre-owned equipment to installing a new Heidelberg Speedmaster SX74 — the first-of-its-kind in Amritsar, Printwell’s journey has been remarkable.

A top-seller in its class, the Speedmaster SX-74 builds on Heidelberg’s perfecting legacy, combining technology of the XL class with the tried-and-tested SM platform, delivering productivity improvements of up to 30% over SM peers, at price points lesser than XL counterparts.

Best-suited for commercial printing and packaging jobs in mid-size format, the SX-74 supports a wide spectrum of substrates from thin sheets to boards, ranging in thickness between 0.03mm and 0.6mm. Shorter makeready and throughput times, with production speeds of up to 15,000 sheets per hour, render the press ideal for short-run jobs.

“With quicker makeready and high speed print output, the SX-74 is a precise fit into our commitment of delivering on-time, top notch work,” said Gurinder Singh.

Designed for eco-friendly operations, the Speedmaster SX-74 cuts alcohol usage to 3% from 10%, saving 172 litres of alcohol for every ten million printed sheets. This is done by using special rollers in the alcohol dampening system.

“The SX74 is equipped with surface technology to enhance service life and extend wash-up intervals,” said Peter Rego, business head, equipment sales of Heidelberg India. “The colour Assistant Pro component enables fully-automated monitoring of the ink fountain liner and self-calibration of ink zones, speeding up the inking unit response by 50 to 70%,” Rego added.

Heidelberg’s proprietary Intellistart feature incorporated in the SX-74 compares the current press status with parameters of the next job, and generates the complete sequence of operations to be performed to change jobs intelligently and dynamically. On average, the Intellistart facilitates 70% fewer operations for every job change, with schedulable setup times and constant time savings.

“Integration of the Prinect Press Room Manager with SX-74 empowers the user to control all pressroom operations from the office. A user can monitor the current job, production speed, make-ready requirements, paper usage, idle time and much more. The Prinect software manages information to guarantee automatic and timely delivery of print jobs to production,” Rego said.

“The SX 74 gives us incredible firepower to scale up our offerings, while ensuring competitive advantage. We are well positioned to capitalise on the opportunities ahead,” Gurinder Singh concluded.

See All

See All