Top Products – Ancillary

What are you looking for at Labelexpo India 2016 – a new press, pre-press or post-press equipment, labelstock, or other ancillary products? Whatever it may be, there are choices galore at the four-day show, which begins from 17 November at India Expo Centre, Greater Noida. For your easy reference, PrintWeek India brings you a handy dossier of top products on display at the premier label event.

In ancillary products, you have the newly developed Smartscan system from Erhardt+Leimer; LA1

16 Nov 2016 | By PrintWeek India

Erhardt+Leimer (Stall B 24)

Smartscan

The newly developed Smartscan system offers inexpensive access to print image monitoring in label printing. In fact, the system is multi-talented. It has a video function with zoom, it enables 100% print image inspection, and splice detection and detection of missing labels and un-removed matrix. You can choose different functions as you require and combine them building block-style into a perfect system for your requirements.

Also see the company’s new web-guider for narrow-web applications: the DR 2375 from the Elguider product family.

GEW (Stall F3)

LA1 LED UV system

The company will display a comprehensive range of UV curing system comprising mercury arc systems, LED systems and hybrid systems together with the fully hybrid Rhino ArcLED electronic power supply.

But the focus will on the new, fully air-cooled LED UV curing system lamphead, LA1, which GEW will bring to the Indian label market. Introduced in June, the LA1 is compatible with the existing ArcLED systems without the need for external chillers, pipes or coolant.

The LA1 is an LED UV curing solution that is able to perform without the added infrastructure and maintenance required by water-cooled LEDs while enjoying the benefits of the efficiency, reliability and extended life cycles of LEDs.

Printing presses that operate with ArcLED technology can be upgraded from arc lamps to LED to benefit from both technologies with the same power supply, controls and cooling system.

Shavo (Meech Shavo Tech) (Stall H40)

TakClean and CyClean web cleaning systems

The Indian representative for UK-based Meech will show the power of web cleaning technologies to the label industry, TekClean. There is a need to minimise wastage. Again, achieving higher levels of productivity is a key priority for label printers and converters, who often struggle to determine the best solution for removing contamination from their web process. This is what makes this product important.

TakClean, a tacky roller contact system, uses elastomer rollers to remove dry, unbonded contamination from a moving web, which is then transferred onto adhesive roles where it is trapped. The design of the system also allows operators to see the contamination being collected on the adhesive roll. Meeach’s CyClean, a non-contact system, is a solution for substrates carrying higher contamination levels. The system is capable of removing 0.5 micron contaminants and will deliver higher levels of cleanliness for label printing applications.

Look out for a compact in-mould labelling (IML) generator, the latest product introduced by Meech in the run-up to this show.

Must see | Royal Coat (Stall K25)

IST Metz MBS range

Did you know that LED technology is expected to achieve a market share of around 30% in 2016, a significant rise compared to previous years? Well, a Yole market research institute study tells exactly that. LED technology currently makes up the greatest proportion of adhesive curing and inkjet printing, but it is also increasingly requested in label printing. So get ready to see a range of new IST Metz MBS system in whose housing either a UV lamp or LED technology can be used at the Royal Coat stand. The new hot swap concept for Lampcure and LEDcure systems allows users to interchange between both UV technologies at any time.

On the Royal Coat stand also see a range of Zecher anilox rollers. According to Sunil Talpade of Royal Coat, Zecher has developed a wide range of engraving technologies. Especially, Zecher's latest innovation, SteppedHex Technology. It helps deal with the daily challenges; and offers tailored solutions in the most optimal and economic way.

Tresu / Capital Graphic Supplies (Stall H1)

FlexiPrint IMW E-Line and FlexiPrint Reservoir

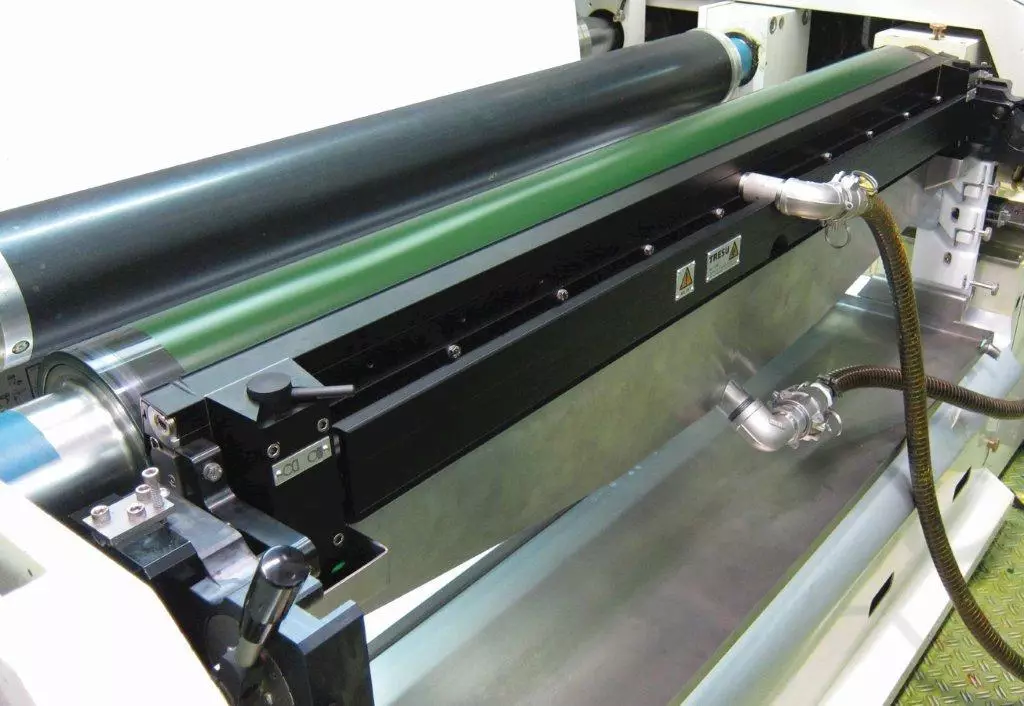

The Tresu Group will showcase ancillary equipment, including supply systems and chamber doctor blades, for controlling and automating ink coating supply in narrow and mid-web flexo printing presses. Two products, the FlexiPrint IMW E-Line and FlexiPrint Reservoir, will take the centre stage at the Tresu stall. The company is represented by Capital Graphic Supplies in India.

The FlexiPrint IMW E-Line chambered doctor blade with widths of up to 1,800mm (70.8-in) and speeds up to 500m/min (1,640 ft/min) can reduced ink and substrate waste, uniform print quality, increased press speeds, shorter cleaning times and reduced emissions, claims the company. The closed-cassette FlexiPrint Reservoir, which needs no pump, operates at press speeds of up to 300m/min (984 ft/min).

Also see Tresu’s lightweight carbon fibre chamber doctor blades up to 6,000mm (236-in) width, which features a top-coated ink-repellent surface, offering protection against detergents and adhesives with pH values of 9.0 and above, and easy cleaning. Tresu says the curved inner surfaces maximises volume and facilitate controlled discharge.

Unique UV and Light (Stall J17)

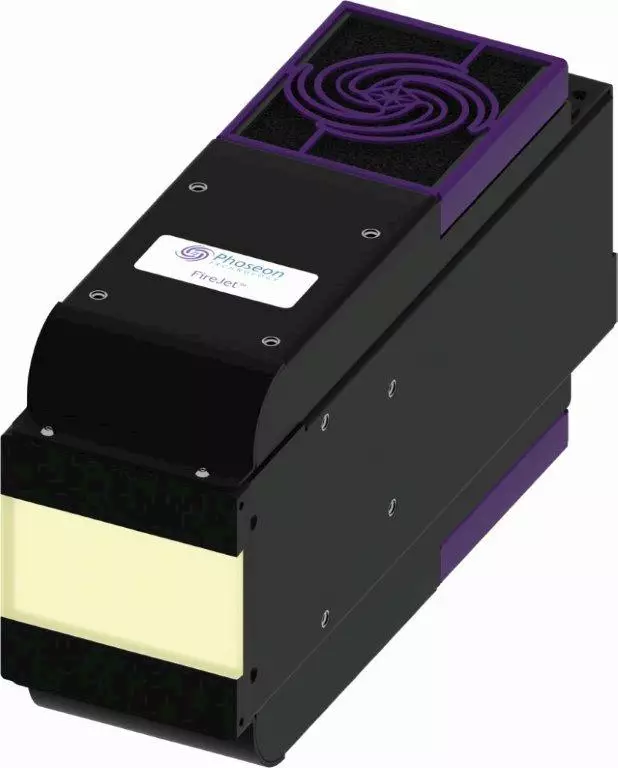

Phoeseon UV LED system

UV LED is the future, claim experts. And Vasai-based Unique UV and Light, which represents Phoseon Technology’s mercury arc UV curing systems for over a decade, will bring the Phoseon’s UV LED curing system at the show. The UV LED system will replace the existing mercury-based technology for many valid reasons, says Sunil Daddikar of Unique UV. Daddikar claims Phoseon has supplied the UV LED flexo solutions to Gallus, Mark Andy, MPS and Nilpeter. Unique will also showcase its own make, Unique UV curing systems, for narrow-web and wide-web applications.

See All

See All