Sri Kriscon’s business surge amid Covid-19 prompts Bobst investment

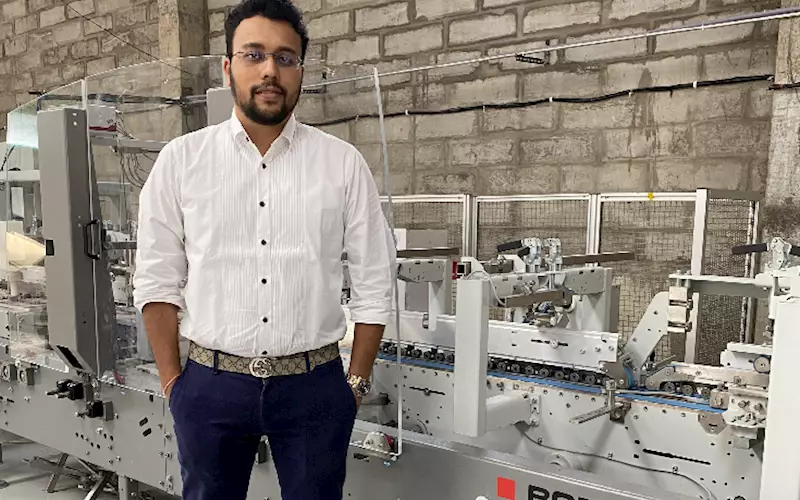

Chetanya Soni is not as worried as the rest of the industry. The director at Sri Kriscon Industry is coping with the pandemic which continues to upend many businesses.

19 Oct 2020 | By Noel D'Cunha

Sri Kriscon added new clients during the lockdown, which Soni said, drove these clients to produce hygiene-secure products by the consumers who would rather not choose their requirements, which are not packaged. The surge in demand has also prompted the company to invest in Bobst’s Novacut 106 E 3.0 die-cutting, Ambition 106 A2 foldergluer machines, and Heiber & Schroeder Speedliner machine.

Sri Kriscon operates as a monopolistic player, supplying internal coated packaging to ice-cream and butter boxes to clients in Madhya Pradesh, as well as packaging to clients beyond the state.

The clients include the Sanchi Group, Johnson Endura, and con-fectionery manufacturers in Indore, among others. The surge in business created a bottleneck in its finishing division, which was equipped with Chinese and Indian-make die-cutting and folder-gluers. “These machines had limitations in terms of speed and quality, plus types of folding it could perform.

Hence, we had to perform certain folding jobs manually, which delayed our fulfilment time.” In today’s time, Sri Kriscon is converting almost 350 tonnes of paper-board a month and while overall the Kriscon industry produces 12,000 tonnes per year. “As we serve the dairy and pharma companies, we had the permission to work at full pace, but were constrained by the capabilities of our existing machines’ speed to produce more,” said Soni.

That’s when Soni decided to invest in Bobst finishing equipment, which according to Soni, has the best-incla ss features. “We compared the Chinese and Bobst machines and found that the Chinese machines would perform well for only maybe three to four years, and then start having issues.

On the other hand, we saw the Bobst machines performing consistently with assured longevity,” explained Soni on his decision to opt for the Bobst machines. The Bobst Novacut 106 E 3.0 is a new third generation die-cutter with new maximum size format 760×1,060mm.

The technological changes are geared towards faster job changeovers, reduced stoppages even further, more flexibility for operators and easier job setting and hence resulting in more productivity. According to Soni, his company was looking for a die-cutter with high registration accuracy and reliability due to criticality of their jobs.

The proprietorship family business was started by Soni’s uncle in 2015 as a paper business, with Soni, who is a chartered accountant, joining the business in 2017. The 39,000sqft Sri Kriscon plant has a total of 1,100 employees, 250 of whom are in the packaging plant. At present, Sri Kriscon’s packaging business is around Rs 25 crore, and it hopes that with the new Bobst it will be much more.

“When I started the business back in 2018 my motto was to provide a good quality product considering time, accuracy, and consistency in mind. We hope the new Bobst machine will boost our turnover,” concluded Soni.

SRI KRISCON FACT FILE

- Established in 2018

- Location: Indore

- Speciality: Packaging

- Equipment: Heidelberg CD: 102 six-colour UV presses; Bobst Novacut 106 E 3.0 die-cutting and Ambition 106 A2 folder-gluer; Heiber & Schroeder Speedliner; to old Bobst die-cutter; and Indian and Chinese machines for packaging finishing

See All

See All