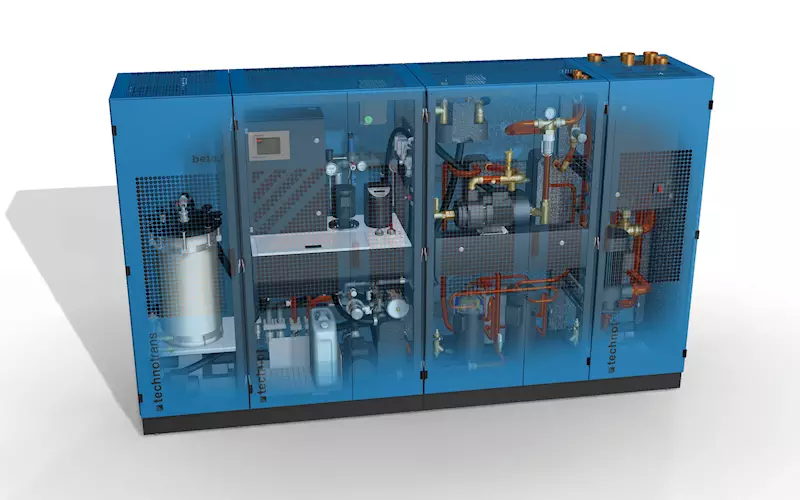

The German press auxiliary manufacturer, Technotrans, has introduced a combination unit Beta.c eco+ modular solution for dampening solution circulation and ink unit temperature refrigeration unit based on digital scroll compressor technology.

The technology uses a patented free-cooling function, which helps to lower the CO2 emissions and energy costs of offset printing applications. The cooling system adapts to the demand of the printing with the help of the digital scroll technology and cools only as required by the load.

Peter Böcker, head of sales of Technotrans AG, said, “The current intake decreases to approximately 10% of the nominal current.” He further explained, “The automatic control enables substantial cost-savings, particularly during partial load operation."

The temperature control circuit pump is frequency-controlled. "Up to 80% of the drive energy can be saved thanks to the adaptation of the pump output," informed Böcker. As a result, “The total energy consumption can be reduced by 50% in combination with the speed-controlled cooling water pump beta.ps eco and also result in cost savings,” explained Böcker.

The system with its measuring and dosing systems also saves on additives. The consumption data is automatically recorded. Optionally, Technotrans also offers the Beta.f dampening solution fine filtration system for a long dampening solution and filter service life.

The efficiency of the system has been certified by BG ETEM.

R M Associates is Technotrans' agent in India. Together the companies have been promoting the sales of chilling systems, cleaning units, recycling processes to some of the leading newspapers and print firms in the country.

See All

See All