Valco Melton introduces new inline print inspection system for corrugation converting

Gluing and inspection system specialist Valco Melton’s ClearVision division has introduced PrintChek, a camera-based tool for inspecting the total width of every corrugated sheet in a flexo folder-gluer or die-cutter and analysing it for print quality.

03 Dec 2021 | By Noel D'Cunha

The patented technology, available to the Indian market, can compare each box, inspect with the remove standard and highlight areas of concerns from spots and hickeys to colour registration problems, stripes, scratches and smeared, ghosted or missing print. Along with defect detection, PrintChek can read and evaluate barcodes for quality and assess the geometry of the sheet for size, skew and trim.

Increasingly, flexographic printing on corrugated secondary packaging is coming under scrutiny from customers whose brand identities are clearly displayed on boxes and trays or for whom important text and information is printed on the box that must be correct and legible. “Some quality managers will report that printing defects are not among the top three issues that they deal with throughout the year but with point of purchase boxes/trays it can be the number one complaint. In addition, print quality expectations of large key accounts are increasing and exceeding the ability of your flexo presses or operators to scrutinize output sufficiently to prevent future complaints,” explained Ravi Kiran, director at Valco Melton India Engineering.

The PrintChek is fitted with multiple cameras installed above (top-print) or below (bottom-print) the sheet along with light modules to illuminate the sheet. Line-scanning cameras take images as the sheet passes and the image is re-assembled in order to evaluate. “Minimum defects down to 2.5mm are visible. Colour measurements of a delta-E value of 3 can be resolved for accurate inspection of ink recipes and matching to desired corporate colour standards,” said Ravi Kiran.

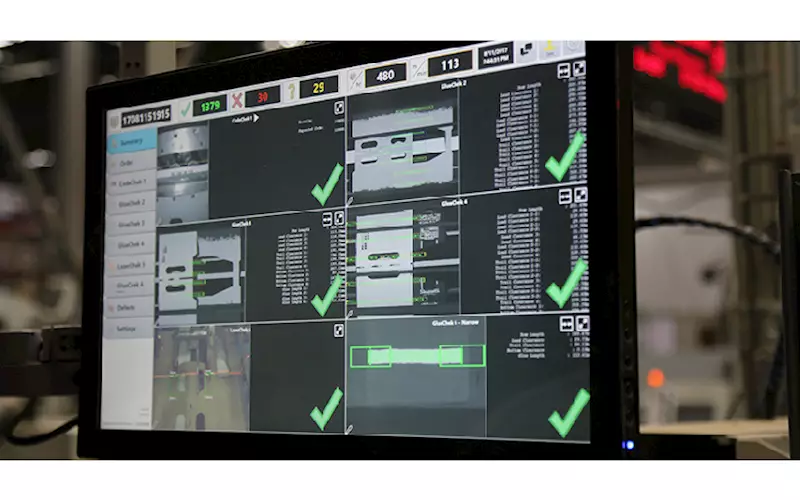

PrintChek uses Valco’s familiar ClearVisionBoxChek 7, an interface to activate desired inspection tests, set tolerances and view images. “The live image is always visible on screen and defects are visible in the defect viewer that sorts images, provides close examination opportunities and highlights reasons for the defect being identified,” said Ravi Kiran. If there is no viable PDF standard available to compare to, a sample box can be run as a “golden standard.” Defect data are stored in SQL format and defect images are stored for later inspection.

Valco’s MeasurementChek continues to serve as both a local and remote access point for production data, per box details and all of the data are stored on the local device, not on the cloud.

See All

See All