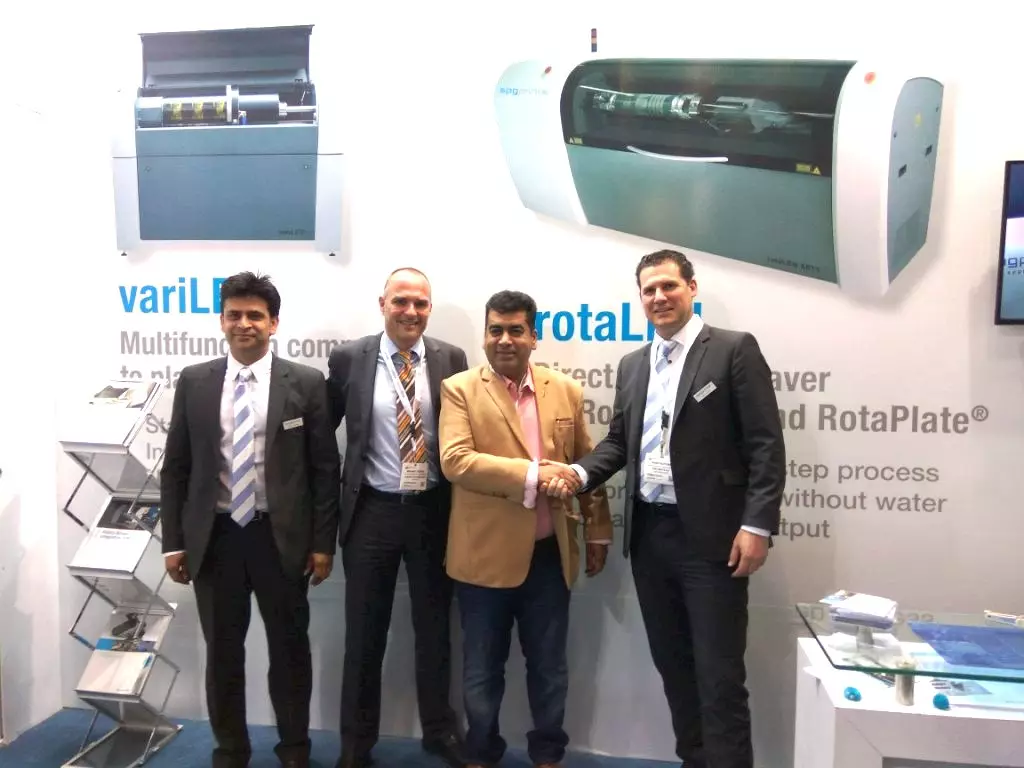

Zircon signs Xeikon and Rotalen deals; Kwality signs Xeikon

Noida-headquartered label specialist Zircon Technologies has booked two Xeikon 3500 digital presses and a Rotalen direct laser engraver manufactured by SPG Prints, all India first, which, its managing director Sanjeev Sondhi, said, will “increases the scope of applications and boosts productivity”. Also, New Delhi’s label specialist, Kwality Offset Printers has made an investment in a new Xeikon 3030Plus.

21 Nov 2016 | By PrintWeek India

Zircon books two Xeikon 3500 digital presses, India’s first

The investment in two Xeikon 3500 digital presses announced on the third day of Labelexpo India 2016 marks Zircon’s foray into digital.

Very recently, Zircon invested in a new Omet, which has been installed at one of the two plants in Dehradun. The company also has a plant in Chennai. Besides, the Omet presses, Zircon plants are equipped with five Mark Andy narrow-web flexo printing presses in operations, a screen printing setup, plus Rotoflex inspection, slitting and rewind systems as part of its post-press fleet.

“Digital is still struggling to gain a foothold in a predominantly flexo-based Indian label industry,” said Sondhi. “But change is needed, and with Xeikon’s print capabilities can convert some of the applications, profitably. Going ahead, we will also try and create a market for ourselves, which will be addressed with this new investment.”

The five-colour Xeikon 3500 can print on substrate width from 10 to 20-inch at a maximum speed of 19.2 m/min. “Zircon is a volume printer, so he will try and run some new type of labels in terms of variable content, which will benefit him,” said Bent Serritslev, managing director for Xeikon in the Asia Pacific Region. “The press offers a combination of 1200x3600 dpi addressability and 4-bit variable dot density, enabling adding micro text, for instance, for anti-counterfeiting applications.”

According to Sondhi, the Xeikon 3500 offers one-pass white, even on heat sensitive PE and direct thermal label substrates. “We hope to create perfect images on transparent as well as metallic label stock. With the Xeikon’s no-click module, we now have a solution that is efficient and cost-effective.”

Zircon buys SPG Prints’ Rotalen, India’s first

In a bid to bring rotary screen-making in-house, Zircon Technologies has invested in India’s first Rotalen direct laser engraver manufactured by SPG Prints.

The Rotalen engraves images onto RotaMesh and RotaPlate screen material in a one-step dry and digital process. The machine features a CO2 single beam laser and a resolution of 4,000 dpi.

Speaking to PrintWeek India, Sanjeev Sondhi of Zircon Technologies, said, “In India, the use of rotary screen is limited to printing white and tactile effects. However, there is wide spectrum of applications that rotary screen can deliver.”

In order to explore these screen applications on a flexo press, Zircon has invested in four screen units including the two units on its recently installed 10-colour Omet Xflex X4.

“We have plans to add two more screen units and this investment in Rotalen will enable us to make rotary screens in-house to cater to the six screen units,” he said.

Zircon employs a workforce of 275 persons and operates out of a shopfloor area measuring 100,000 sq/ft. Another 50,000 sq/ft additional shopfloor area is under construction. Zircon has in the last nine years of existence invested in an average of more than one press each year.

Kwality Offset Printers to install the 3030Plus shown at Xeikon stand

New Delhi’s label specialist, Kwality Offset Printers, is all set to add digital to its offset and flexo operation, expanding its operations with digital short-run capabilities, with the investment in a new Xeikon 3030Plus.

Chhatwal (second from left) and his son Krish flaked by Team Xeikon

The company specialises in folding carton, wet glue and self-adhesive labels and is equipped with three offset, including a Heidelberg and Manroland multi-colour presses and three Mark Andy flexo presses.

“We have quite a big chunk of work which is typically in the 1,000 metre range,” said Rajeev Chhatwal, director at Kwality. “We are also looking to expand our portfolio by offering new products to our existing clients, as well as add more clients.”

Established by Chhatwal’s father late Narinder, Kwality began as a paper cup manufacturer in 1962. Over the years, the company added labels and folding cartons to its portfolio. Today, the business is managed by Chhatwal and his son, Krish who entered the business five months ago.

The company converts around 6-lakh sq/m of labels and around 80 tonnes of paperboards per month. Besides, the presses the company has Kodak pre-press kit for both offset and flexo operation, and print enhancements like foil stamping, embossing, textured varnishes and screen effects are produced using equipment from Germany and the US. A Rotoflex machine inspects the products for quality.

The Xeikon 3030Plus four-colour plus white dry toner-based press is capable of delivering 1,200dpi prints at a top speed of 15 metres per minutes; allows use of substrates without specific pre-treatment.

“With the Xeikon 3030Plus, we have brought all the three operations in house,” said Chhatwal.

See All

See All