Zund, Caldera launch pre-press automation software Primecenter

Cutting systems manufacturer Zund and French software specialist Caldera have jointly launched a new pre-press automation software – Primecenter – to help wide format digital printers to save time as they prepare jobs for printing.

19 Jun 2020 | By Aultrin Vijay

Zund, in association with Caldera, has announced the launch of Primecenter, a new software solution that "creates an ultra-efficient pre-press workflow", on 15 June 2020. Apparently, the launch was supposed to materialise at the Drupa show, which was postponed owing to the Covid-19 pandemic. Developed in cooperation with Zund, the Caldera-owned and branded product has been available for delivery from June 1.

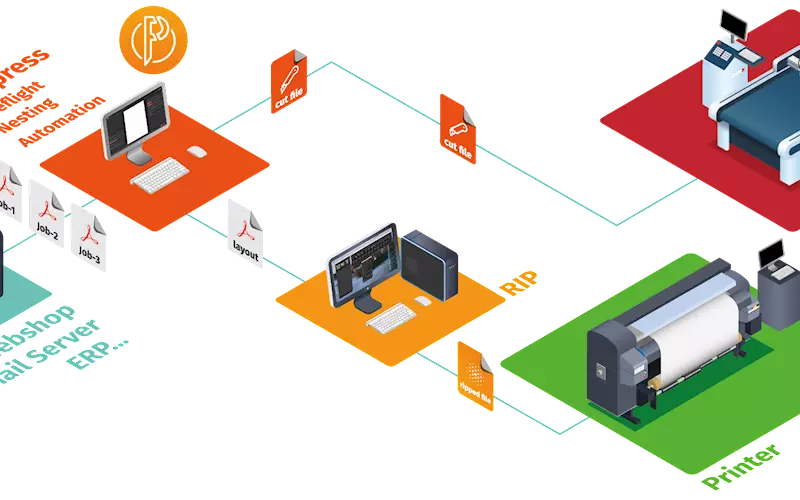

According to Zund, Primecenter simplifies file preparation and output, allowing users to configure their workflows – from design to print to cut – with the level of automation that best meet their needs.

Explaining the need behind creating the software, Prasanna Venkatesh, managing director at Zund India, said: "Workflow management is becoming more complex and so is the coordination of internal production processes. More often, web shops are integrated as an additional sales channel. This tends to increase the number of jobs while decreasing the run length. From a production standpoint, it heightens the need for a highly flexible, easy-to-use file-prep procedure. Which is exactly why Primecenter was created."

The company claims that an user can take the artwork and create a print-ready layout with just a few steps. "In doing so, the user can choose to go through the required steps manually or create a fully automated process," a press note shared with PrintWeek stated.

The target audience for the new product includes all sizes of print shop and the core users will be the pre-press operators who prepare files for production. Primecenter’s remit includes unique actions designed to automate roll-up, POS, stickers, backlit, banners production and more. For larger print operations, the software reduces the multitude of repetitive daily tasks faced by prepress operators.

The note further detailed that Primecenter offers the user complete freedom of choice as to the desired degree of pre-press workflow automation, intelligently. "Primecenter is available in Basic, Pro, and Max versions. The level of automation can be adapted to changing requirements at any time. Because of Primecenter's open interface, the software can output to any RIP/printer and any cutter," it said.

The company said graphics can be nested contour-based at the push of a button or in an automated process. This results in optimal material yield with minimal waste and shorter production time.

"Often, maximizing material usage is not the primary concern. That is where Primecenter offers an array of alternative nesting methods," the release said. For example, jobs can be ganged using metadata to simplify sorting, if they consist of multiple parts, or to have them be ready for delivery at the same time.

According to Venkatesh, the software makes it very easy to create trim boxes, define bleed, or add register marks. "For applications involving transparent materials or transfer print, there is an option to mirror the layout. Primecenter also lets the user integrate selected metadata in the output file."

The information printed along with the job facilitates job tracking and, once cutting is complete, quick and correct attribution of cut parts to the respective orders. The PDF files are verified by the Preflight Check tool after import and before export.

"Optionally, each step of the process may be automated by hot folders, filename conversion or by using an XML-based job ticket exported from an MIS or ERP system or a web shop. Primecenter handles layout preparation and preflight checking autonomously and reliably – the perfect basis for an efficient, cohesive workflow," he added.

According to Zund, the integration of its Zund Cut Server and Cut Time Estimation makes production planning faster and more flexible. The visualisation of the expected production time creates transparency. "At any given time, this makes it easy for the user to keep track of time allotments and with it, the ability to guarantee close adherence to specified delivery times," the company stated.

Venkatesh said that there are many bottlenecks lurking in preparing layouts to be printed and cut, such as inflexible production processes, manually generated trim boxes, manual preflighting and nesting of designs. "This can lead to tremendous inefficiencies and production delays. Primecenter adapts to the workflow requirements of the individual print service provider, not the other way around."

Meanwhile, Caldera’s product manager Arnaud Fabre, said, “We’ve developed Caldera Primecenter to provide our customers with the right tool at the right place. Not only can they save time by employing this new prepress solution, but its optimisation features can also result in substantial media savings too.”

See All

See All