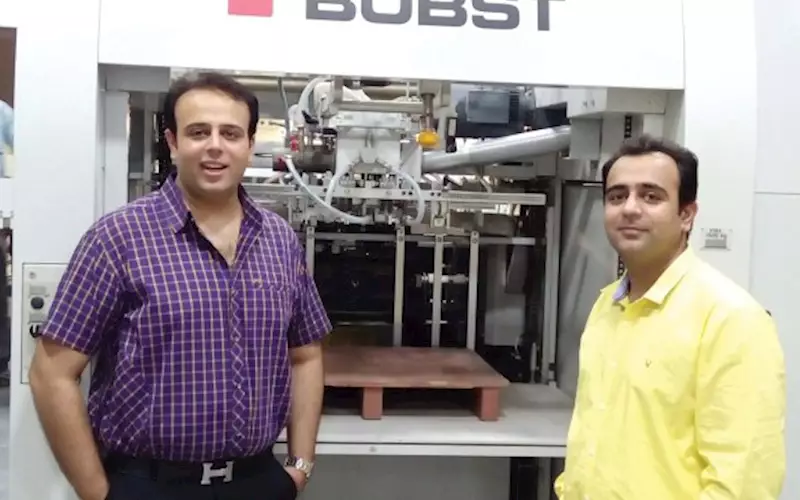

Me & My: Bobst Novacut 106

Company Name:Shiv Offset

24 Jul 2015 | By Rahul Kumar

Key person: Jiten Shadija.

Model & Configuration: A Novacut 106 die-cutter and a Novacut 106 die-cutter with stripper. We also have a Bobst Ambition folder-gluer.

Year of installation: The first Novacut 106 and Ambition were installed in 2012, while the second Novacut 106 with stripper April, 2015.

City: Sajida, says, Indore is a hub for the pharma and food industries.

How has the kit benefitted you: We do not cater to any domestic work in MP, but across India and directly export to 11 countries. We opted for the first Bobst because of it accuracy, maintenance, and the brand and continued with Bobst for the second kit, because we can use the same tools on both the machines. We can plan same job on both the machines. And maintenance. It has improved our productivity and quality. And though Bobst machines are expensive, the volumes we do and better margins because of the quality, has helped us recover the investment in good time and become profitable.

Production record: We do around 22-lakh cartons per day.

Commitment you could fulfil: We can deliver 10-lakh cartons within 12 hours of the order received.

About Bobst: Our competitors are working on used Bobst, which was bought 20 years ago. I expect the ones I have to serve me for 35 years. Bobst machines excellent both in terms of productive and quality, but they need high levels of maintenance to achieve that. We are happy with both.

Future plans: We have ordered an Expertfold, which is expected to be delivered by November this year. By the end of this year, we are also targeting 45-lakh cartons per day, and that’s our aim.

See All

See All